Mar. 16, 2025

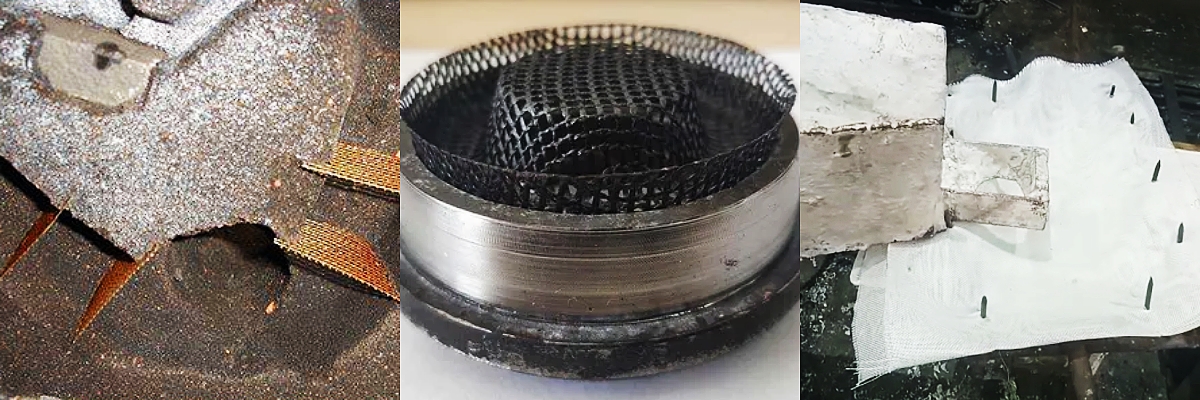

Although Galvanized steel and iron wire mesh filters are commonly used for low pressure castings filtration at present, they are cost effective with good strength and flexible on shapes and sizes.

But a huge number of Fe element will be added to the aluminum castings during and finish filtration. Also, the recycled aluminum liquid can not be used again, this will make cost increased.

In addition, this filtered liquid will make the castings mechanical strength lower.

Now there is a new and better material to perfectly replace it to avoid the above disadvantages.

Fiberglass fabric mesh filters for aluminum filtration are specially designed and woven for the diffusion and filtration of molten aluminum. High twisted yarns are used to control strand diameters and resist fattening or distortion under pressure from contact with molten metal.

The integrity of the weave pattern is maintained by the use of phenolic resin, and by the use of leno or plain construction in high density. Regular coating and carbonized treatment are both available.

E-glass fiberglass mesh filters for molten aluminum filtration are designed and woven for the diffusion and filtration of molten aluminum.The molten aluminum is very easy to be oxidated when touched with air.

The pure molten aluminum is more easier to get during primary melting, foundry casting and scrap recycling with filtration by this fiberglass mesh filter.

The main types can be the one without coating(white color) and with coating(yellow or dark brown color) and smokeless carbonized treatment(black color).

Fiberglass Cap Filter For Car Wheel Hub And Pistons

Apr. 14, 2025

Contact Us

+86 158 3011 4065

Guoruiyuan Building, ShengLi North Street, Chang'An District, Shijiazhuang City, Hebei Province, China.

Navigation

Navigation