Dec. 26, 2024

(For Aluminum Casting Filtration)

There are many reasons for aluminum pollution, Such as:

1. In the smelting process, aluminum is exposed to the furnace atmosphere in a molten or semi-molten state, easy to oxidize, easy to react with water vapor and absorb hydrogen, easy to form various forms of non-metallic slag (such as furnace lining debris, chloride, carbide in flux, etc.) and coarse metal intercompound particles and so on.

2. Non-aluminum impurities are carried in during the process circulation by some of waste materials maked up the charging material.

Because the waste is coming from the process waste and scrap during each process in factory and the waste outside the factory, so, the composition is complex due to different way as well as the quality is poor. These impurities often make the billet produce bubbles and inclusions, which seriously affect the purity of the metal melt, thus further affect the processing properties, mechanical properties, corrosion resistance and the appearance quality of the product.

One kind of High temperarure Carbonized Fiberglass Filter Mesh can perfectly filter the aluminum.

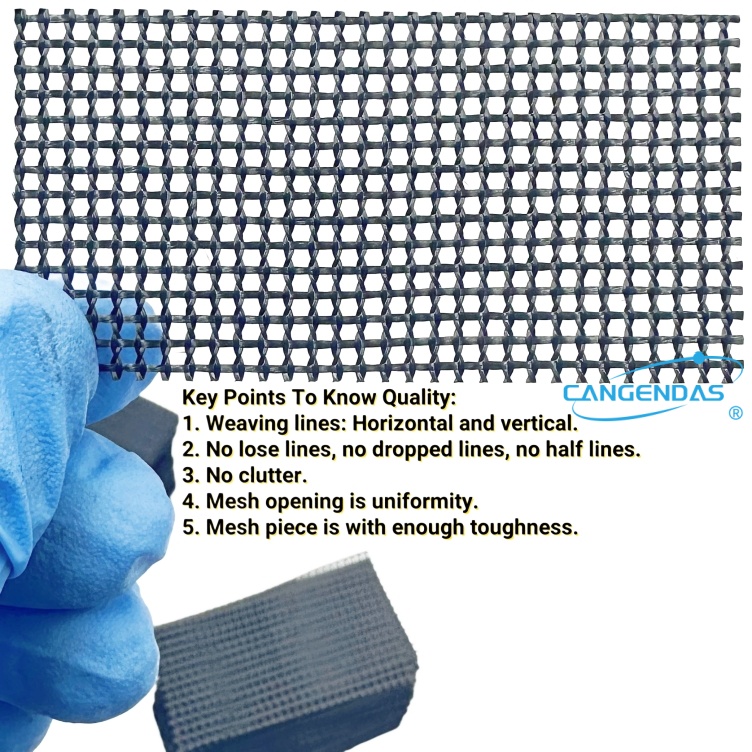

WOVEN FABRIC-Special fiberglass mesh filter is woven by high silica and alkali free fiberglass yarn and woven looms.

HEAT SETTING-Fabric mesh is needed to be heat setting in order to keep horizontal and vertical after woven process

COAT RESIN-Then white fabric mesh is needed to be coated with special resin, which can make it tough enough, finally, it will become brown.

CUTTING SHAPE-Cutting is quite important step during the whole process, there are two cutting ways in our factory, one is by machine, the other is laser light. Usually, square and rectangle are cut by machine, round, fan-shape and other heteroideus are cut by laser light.

HIGH-TEMP CARBONIZE-Final step is high temperature carbonization. This is the most important process. The key points are temperature and time. Can't be more or less and must be absolute precision.

Pieces In Cutting & Cap In Process

For quality inspection: Pieces dimensions, meshing opening, tolerance and toughness are the key points.

1. Pieces dimensions, meshing opening, tolerance inspection:

2. Toughness Inspection:

Fiberglass filter mesh pieces carbonized after high temperature, it becomes easy to be bendy and folded, this is unqualified products. Because toughness is quite important factor that decides quality is good or not.

The pieces can not be snapped when doing toughness test, this is the key point that decides good quality!

Package can be customized with our OEM service. Usually, 100pieces per plastic bag, 10000 pieces per cartons and cartons on one pallet.

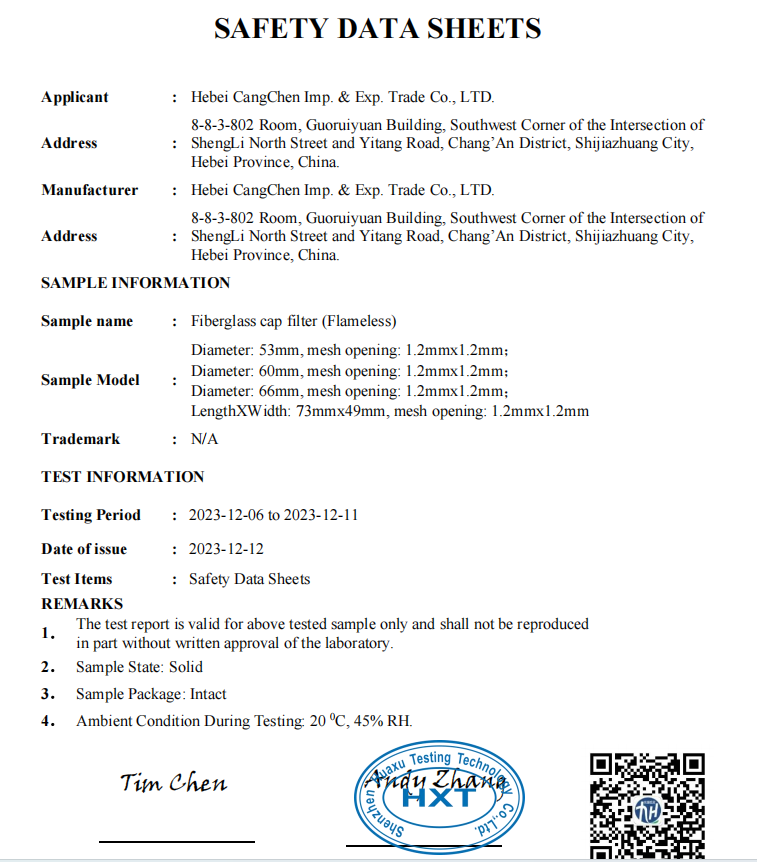

We, Hebei Cangchen, a professional manufacturer of fiberglass filter mesh, with own registered trademark: "CANGENDAS", but also OEM service will also be provided for all customers from the world.

We are a professional factory with ISO certificate and our filter mesh are inspected by strict way as per quality requirements. Our filter mesh has been certified by "SDS".

Fiberglass Cap Filter For Car Wheel Hub And Pistons

Apr. 14, 2025

Contact Us

+86 158 3011 4065

Guoruiyuan Building, ShengLi North Street, Chang'An District, Shijiazhuang City, Hebei Province, China.

Navigation

Navigation