Jan. 15, 2025

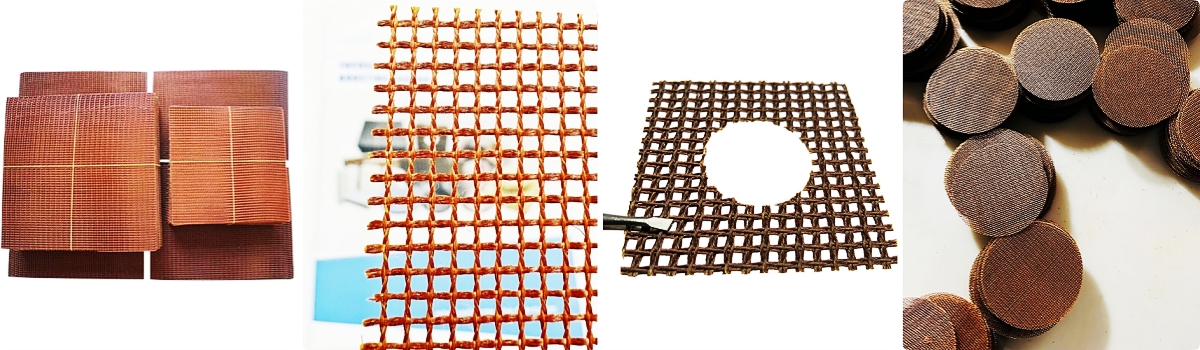

High Silica Fiberglass Filter Mesh is ideal for in-mold filtration of gray, malleable, white, compacted graphite and ductile cast irons, as well as non-ferrous aluminum and copper-based metal alloys and many types of small scale steel casting filtration.

Different Kinds of mesh opening can be chosen to filter different kinds of molten iron and steel.

| Mesh Opening Chosen | White Iron | 1.5mm |

| Gray Iron(Pour weight≤100kgs ) | 1.5mm | |

| Gray Iron(Pour weight≥100kgs ) | 2.0mm | |

| Malleable Iron | 1.5mm | |

| Compacted Graphite Iron | 1.5mm & 2.0mm | |

| Ductile Iron(Pour weight ≤ 100kg) | 2.0mm | |

| Ductile Iron(Pour weight ≥ 100kg) | 2.5mm | |

| Carbon Steel | 1.5mm | |

| Stainless Steel | 1.5mm | |

| Brass | 1.5mm & 2.0mm | |

| Bronze | 1.5mm & 2.0mm |

High Silica Fiberglass Filter Mesh is weaved by high silica fiberglass yarn and coated with special refractory coating. It can effectively remove slag, refractory particles and non-metallic inclusions from molten metals. Made from specially treated silica yarns, the thick type silica mesh filters are capable of withstanding pouring temperature up to 1620℃.

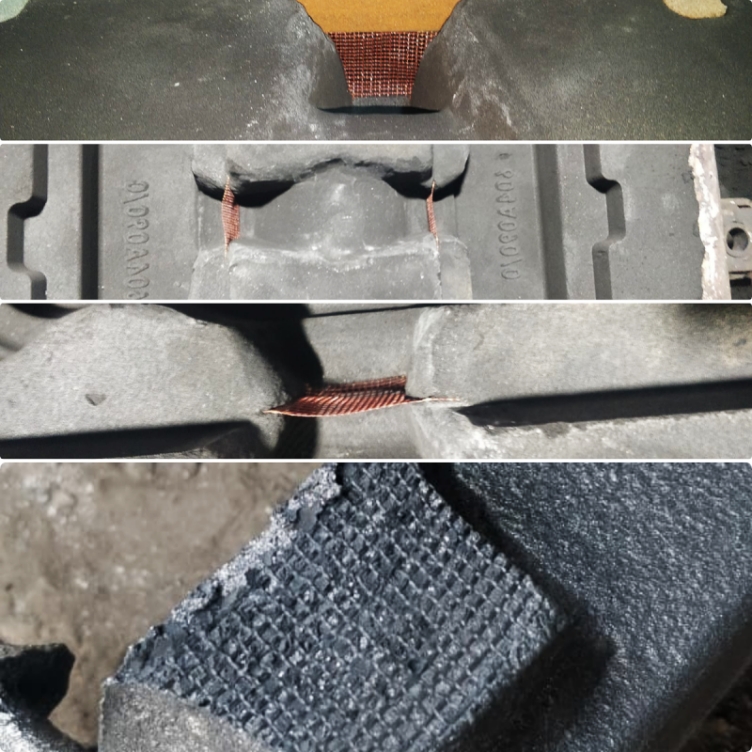

Besides the function of molten metal filters, it could be also used for riser knock-off or de-gating knock-off. Investment casters have also placed the perform cup shape filters in the wax mold gating system to filter metal at pattern entry.

High Silica Fiberglass Fabric Filter Mesh Key Points of Usage:

1. Use area of filter net: F1 = F2 / AxB

● F1: the cross-sectional area of the casting system.

● F2: the original cross-sectional area of the casting system.

● A: the porosity of the filter screen, generally 50-60%.

● B: the filtration rate of filter screen, generally 60-80%.

Therefore, the cross-sectional area of the casting system is generally 2-4 times that of the casting system without the casting net.

2. Position of filter screen:

● Place the filter under the sprue cup;

● Placed on the parting surface under the sprue;

● Three different positions on the lap surface of the runner.

The ultimate goal of Hebei CangChen

Mar. 17, 2025

Contact Us

+86 158 3011 4065

Guoruiyuan Building, ShengLi North Street, Chang'An District, Shijiazhuang City, Hebei Province, China.

Navigation

Navigation