Jul. 25, 2024

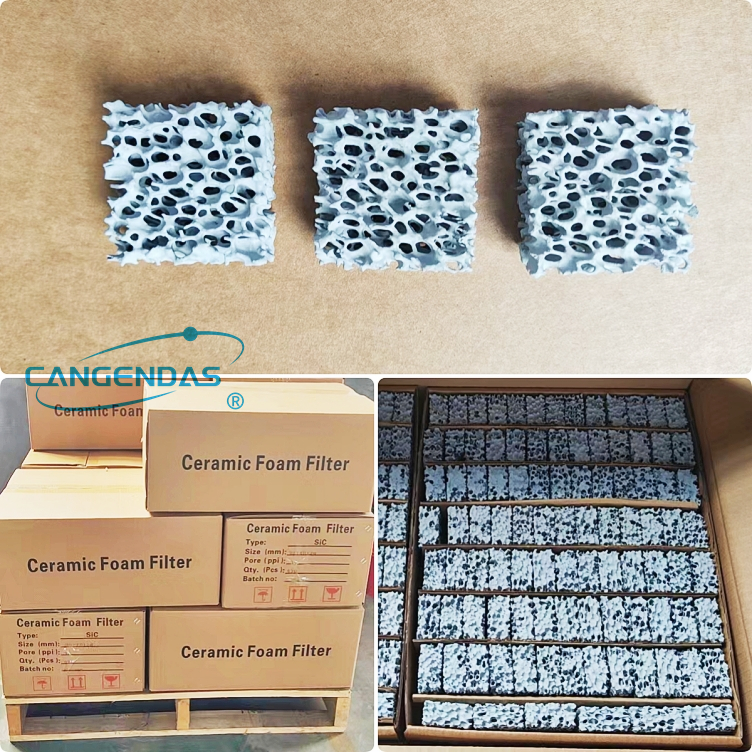

SIC Ceramic foam filters are suitable for the casting of all copper alloys and cast iron because of its high strength, resistance to high temperature impact force and chemical corrosion and operating temperature 1530°C.

SIC Ceramic foam filters can significantly improve the quality of cast iron parts and reduce the rejection rate. They can also be used in continuous casting and rolling processes and can be manufactured to different sizes and thicknesses depending on the runner and pouring weight.

It can effectively remove oxidized inclusions and other non-metallic inclusions by blocking and capturing adsorption of molten copper or molten iron using three-dimensional structure. No matter gray iron, ductile iron, shaft body, cylinder block or complex large pieces, hardware parts after filtering, the quality will be very stable and satisfactory results.

It is also suitable for copper, bronze, brass and other copper alloys, reduce the turbulence of copper liquid and purify the molten copper liquid. What is especially valuable is that the life of copper castings purified by filtration is significantly prolonged in high requirements or harsh environment such as Marine turbine and chemical parts, and it also has good effect on the cast copper parts with surface polishing requirements.

It also plays an important role in the traditional copper industry, electrical and electronic copper industry and continuous casting and rolling technology. Since copper and its alloys, including zinc alloys, have greater specific gravity and produce greater thermal shock during pouring, the use of silicon carbide foam ceramic filters in the copper casting process generally has strict size requirements.

Ceramic foam filters produced by our company adopt imported raw materials from Germany and advanced laser cutting technology, which can meet the requirements of manual modeling and mechanized production line with higher efficiency, and ensure the quality standard requirements of casting factory productization.

Excellent raw materials and advanced production technology ensure quite stable dimensional tolerance of our ceramic foam filters.

Hebei Cangchen, a professional manufacturer of such SIC filters, we have our own registered trademark: "CANGENDAS", but also we have OEM service for all customers from the world. We are a professional factory with ISO certificate and our SIC filter has been passed REACH&RoHS certificate.

Today, a pallet of SIC Ceramic foam filters are exported to India, "Visible Good Quality" helps us get the excellent reputation from our client!

Contact Us

+86 158 3011 4065

Guoruiyuan Building, ShengLi North Street, Chang'An District, Shijiazhuang City, Hebei Province, China.

Navigation

Navigation