Nov. 04, 2024

Alumina Ceramic foam filter is just developed as a new type molten metal filters to decrease casting flaw.

And also as a catalyst carrier for Air Treatment in recent years, plays a vital role in that decompose organic pollutants into pollution-free water (H2O) and carbon dioxide (CO2) to meet high environmental requirements.

Alumina Ceramic foam filter plate is as a carrier, which has a pretty important function for the air purification.

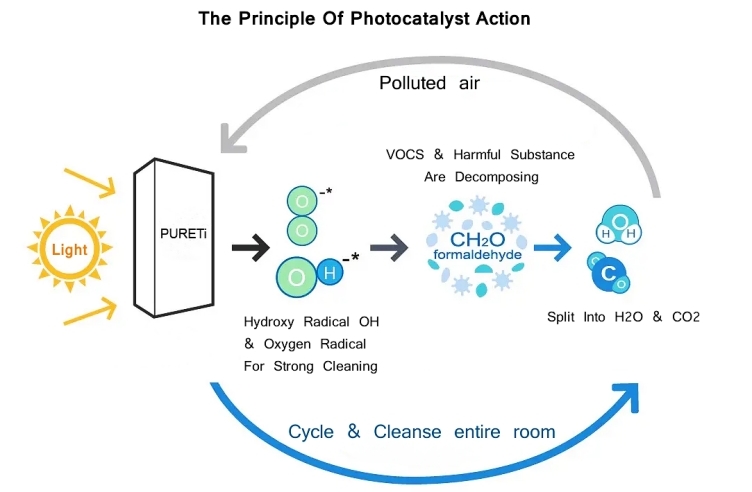

When the photocatalyst is under light irradiation(including sunlight and other natural light), it can make photocatalytic reaction that is similar to photosynthesis, and it can produce free hydroxyl groups with strong oxidation capacity and reactive oxygen species with strong photoredox function.

They can oxidize and decompose various organic compounds and some inorganic substances, destroy bacterial cell membranes and solidify viral proteins, and kill bacteria and decompose organic pollutants.

Also they can decompose organic pollutants into pollution-free water (H2O) and carbon dioxide (CO2).

So, the photocatalyst has strong sterilization, deodorization, mildew prevention, antifouling and self-cleaning, air purification function, which can be meet high environmental requirements.

The characteristics of photocatalyst is to use the oxygen molecules and water molecules in the air to convert the organic matter in contact to carbon dioxide and water.

It does not change itself, but it can promote chemical reactions. Theoretically, the validity period is very long and the maintenance cost is low. At the same time, titanium dioxide itself is non-toxic and harmless, has been widely used in food, medicine, cosmetics and other fields.

Now the applications include but not limited to oil fume gas treatment, indoor air purification, industrial waste gas treatment and wastewater treatment.

Alumina Ceramic Foam Filter Plate is mainly used in the melting filtration of aluminum and aluminum alloys.

It can efficiently filter residues such as oxide slag, oxide scale, non-metallic inclusions and gate groove linings in molten aluminum, and solve the problem of aluminum and aluminum alloys being sensitive to internal defects.

The unique production process and detection method make the alumina filter plate with high opening rate, uniform pore structure and high surface strength.

Available in 7" to 26", mesh up to 60ppi filter plates.

Our company has obtained ISO 9001-2015 system certification.

For three kinds alumina ceramic foam filters, asbestos hemming, fiber paper and expandable gasket.

Today, we exported Right-Angle side alumina ceramic foam filter plate for our Canada Client.

Alumina foam ceramic is a kind of foam material made from high purity alumina. The foam ceramics have the characteristics of uniform porosity, high temperature resistance, heat shock resistance, wear resistance and chemical stability.

Widely used in casting processing, water treatment, chemical industry, environmental protection and other industries.

It is the ideal liquid aluminum filter; Catalyst support, and good sound insulation, thermal insulation material.

Contact Us

+86 158 3011 4065

Guoruiyuan Building, ShengLi North Street, Chang'An District, Shijiazhuang City, Hebei Province, China.

Navigation

Navigation