Jul. 20, 2024

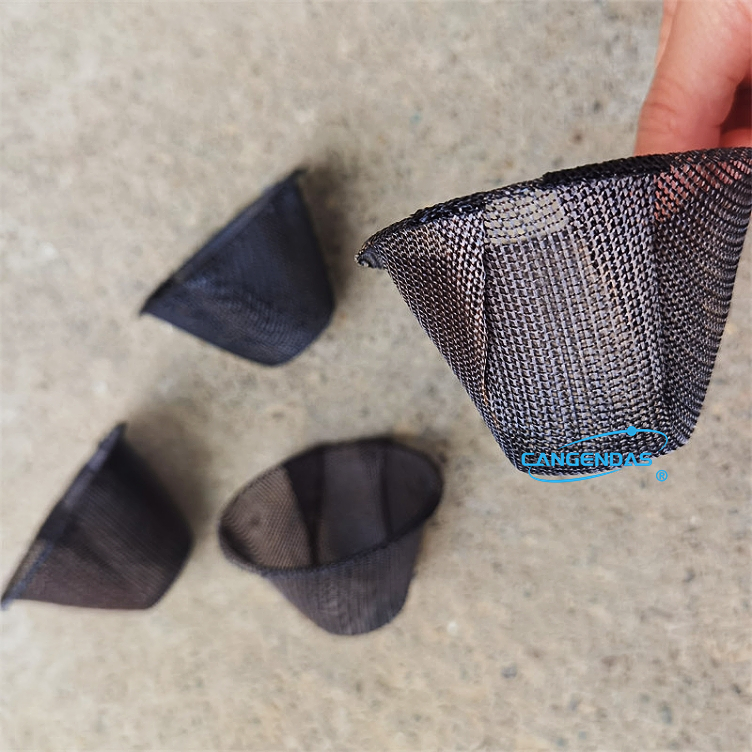

The cap fiberglass filter mesh is made of high temperature resistant fiberglass by special process weaving and post-treatment. Products have become serialized, advanced technology, stable quality.

The cap fiberglass filter mesh cost is cheap, easy to use, it can improve the mechanical properties of castings without changing the metal composition, improve the production quality of castings. At the same time, it is resistant to high temperature and ablative properties, and it can operate at temperatures of about 850 degrees.

Compared with other types of cap type filter, the lower cost, easy to use, does not change the composition of the casting, good slag filtration effect and small air volume have already attracted all clients from the world attention and choose.

Purification mechanism of cap type fiberglass filter mesh

● Cap type fiberglass filter mesh is usually a network structure, which is a non-metallic liquid metal purification device with the required mesh opening. Its porosity is higher, the slag collection surface area is larger, and it can reduce the the Reynolds number of the mesh metal surface flowing through the cast filter, then it can make the filler be more stable and reduce the production of secondary oxidation slag in the mold.

● Since the cap fiberglass filter mesh is placed at the bottom of the gate of the sprue cup, runner or sand mold, the molten metal injected from the sprue cup into the cavity can stay momentarily while passing through the position. The slag can be the main small-density inclusions floating and separating from the molten metal. These inclusions also produce deep adsorption when they pass through regular or irregular grids. This phenomenon can continue to purify molten metal before the pouring cup is filled.

● The role of surface filtration: Surface filtration is a common metal liquid purification function of all casting filters. When the molten metal passes through the casting filter, unfloated or floating inclusions with a relatively large surface area, such as molten slag, are captured by the surface of the casting filter. In addition, the captured inclusions will form a finer filter eye with the cast filter continue trapping subsequent inclusions, thus enhancing the filtration effect. However, at the same time of this surface filtration, with the decrease of the pouring temperature and the increase of the viscosity of the molten metal, as well as the extension of the pouring time, the cap filter mesh will be blocked to varying degrees, thus make filtering effect be worse.

So, the cap filter mesh should be replaced with a new one according to actual casting scenario to keep its best filtering effect.

Product performance of cap fiberglass filter mesh

● The cap fiberglass filter mesh is made of high temperature resistant fiberglass by special process weaving and post-treatment. Products have become serialized, advanced technology, stable quality. Compared with other types of cap type filter, the lower cost, easy to use, does not change the composition of the casting, good slag filtration effect and small air volume have already attracted all clients from the world attention and choose.

● The cap fiberglass filter mesh cost is cheap, easy to use, it can improve the mechanical properties of castings without changing the metal composition, improve the production quality of castings. At the same time, it is resistant to high temperature and ablative properties, and it can operate at temperatures of about 850 degrees.

1. Improve the graphite form in the casting to reduce the graphite size, thinner thickness and slightly curved shape.

2. Change the machining performance of castings and improve the processing speed.

3. Stabilize the metal melt and flow rate, completely protect the cavity and prevent the metal melt from damaging the cavity and causing sand clamping defects in the casting!

4. Prevent the flow of metal melt too fast, resulting in sand expansion, cavity drop, burrs and uneven surface!

5. Eliminate bubbles to increase the density and hardness of the casting and the tensile strength at room temperature.

6. Efficient removal of impurities, reduce casting inclusions, air, slag holes and trachoma defects, greatly reducing the defective rate!

7. The trial production range includes cast steel, cast iron, cast copper, cast aluminum, sand casting, bright casting, wax casting and lost casting, water glass and resin sand casting, which greatly improve the production of castings and reduce foundry costs.

Contact Us

+86 158 3011 4065

Guoruiyuan Building, ShengLi North Street, Chang'An District, Shijiazhuang City, Hebei Province, China.

Navigation

Navigation