Nov. 25, 2022

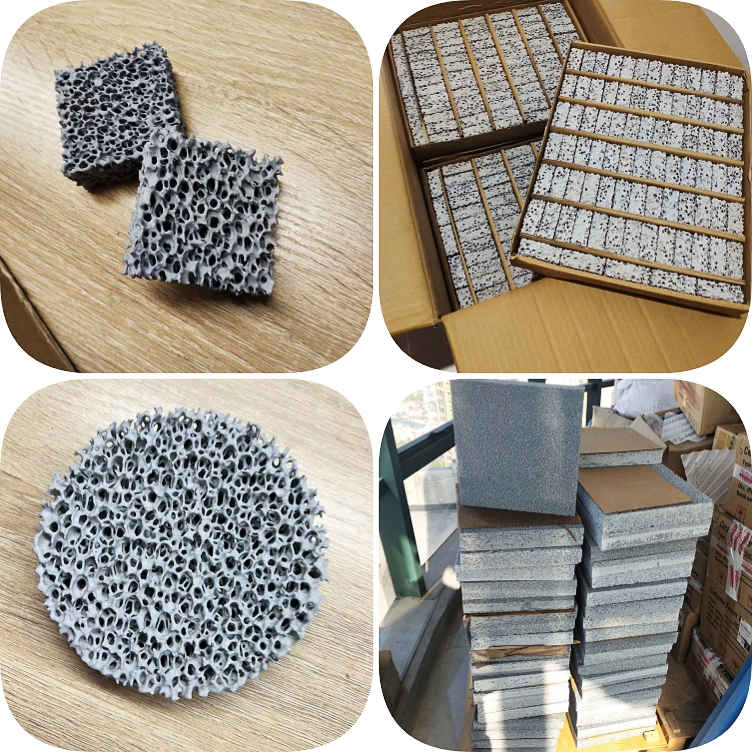

SIC Ceramic foam filters are suitable for the casting of all copper alloys and cast iron because of its high strength, resistance to high temperature impact force and chemical corrosion and operating temperature 1530°C.

● It can significantly improve the quality of cast iron parts and reduce the rejection rate.

● Also can be used in continuous casting and rolling processes.

● Can be manufactured to different sizes and thicknesses depending on the runner and pouring weight.

● Can effectively remove oxidized inclusions and other non-metallic inclusions by blocking and capturing adsorption of molten copper or molten iron using three-dimensional structure.

● No matter gray iron, ductile iron, shaft body, cylinder block or complex large pieces, hardware parts after filtering, the quality will be very stable and satisfactory results.

● Also suitable for copper, bronze, brass and other copper alloys, reduce the turbulence of copper liquid and purify the molten copper liquid.

● What is especially valuable is that the life of copper castings purified by filtration is significantly prolonged in high requirements or harsh environment such as Marine turbine and chemical parts.

● Also has good effect on the cast copper parts with surface polishing requirements.

● Can used for filtration of Alumina alloy.

Do you have requirements of above SIC ceramic foam filters? Let's talk more.

Alumina Ceramic foam filter plate for Smelting Aluminum

Apr. 22, 2025

Contact Us

+86 158 3011 4065

Guoruiyuan Building, ShengLi North Street, Chang'An District, Shijiazhuang City, Hebei Province, China.

Navigation

Navigation