Aug. 08, 2022

The cap-style is woven with special high-twist & high-strength alkali-free fiberglass and special post-treatment. The maximum temperature resistance can reach 900 ℃.

It is widely used in automobile and motorcycle wheels, cylinder pistons, aluminum rods, aluminum materials, aluminum ingots, aluminum plates and precision casting of all types of aluminum alloy casting.

It can effectively remove impurities, reduce turbulence and eliminate air bubbles, thereby improving the quality of castings and reducing costs. At the same time does not pollute the aluminum liquid and affect the chemical properties of the metal. Therefore, aluminum waste containing the filter mesh, aluminum liquid from sprue and the riser can be directly returned to the furnace for remelting, greatly reducing costs.

In the filtration of molten aluminum, the cap filters can remove harmful impurities such as bubbles, ash oxide and various inclusions in molten solution, and improve the yield of casting and the quality of aluminum products. In addition, it also avoids other metal components infiltration into the aluminum solution, so as to ensure the quality of aluminum castings.

The special-shaped cap filter has light weight and high corrosion resistance, which is the key point of the cap type filter. This point makes it very suitable for the direct construction of the underground straight up pipeline engineering and the surface of the pool.

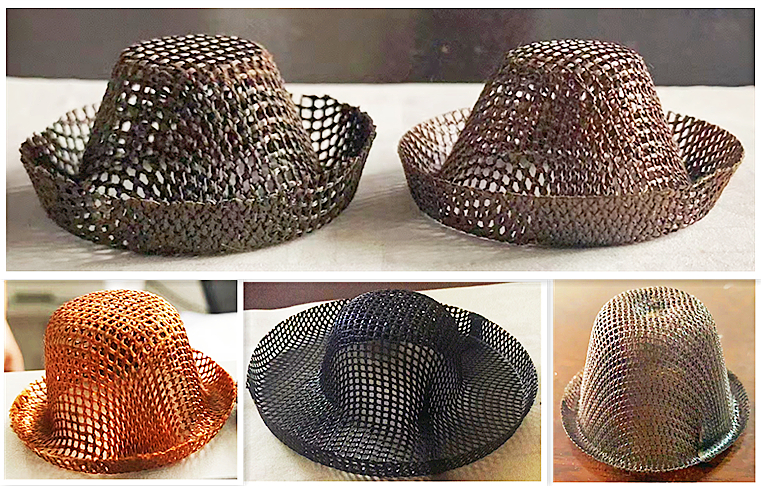

There are Many Shapes Of Fiberglass Cap Filters from China Hebei Cangchen Manufacturer: Black color and yellow color. High temperature carbonized type is better to filter molten metal.

Fiberglass Cap Filter For Car Wheel Hub And Pistons

Apr. 14, 2025

Contact Us

+86 158 3011 4065

Guoruiyuan Building, ShengLi North Street, Chang'An District, Shijiazhuang City, Hebei Province, China.

Navigation

Navigation