Aug. 28, 2022

Manufacturing process

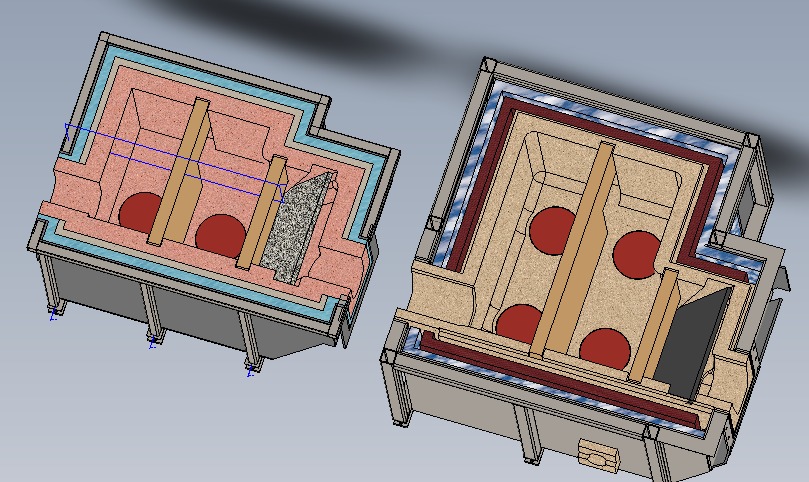

The organic foam sponge with three-dimensional network structure and connected pores is used as the carrier, which is infiltrated into the special ceramic slurry with thixotropy, and a special rolling process is adopted to make the ceramic slurry evenly spread on the skeleton of the carrier, and then finished by roasting at high temperature after drying curing.

Using method

1. Clean filter box

2. Gently put the filter plate into the filter box, and press the sealing gasket around the filter plate by hand to prevent the flow of molten aluminum.

3. Evenly preheat the filter box and filter plate to make it close to the temperature of the molten aluminum. Preheat to remove moisture and facilitate initial instant filtration. Preheating can be carried out using electric or gas heating. Under normal circumstances, it takes about 15--30 minutes.

4. Pay attention to the change of the aluminum hydraulic head during casting. The normal initial pressure head is 100-150mm. When the molten aluminum begins to pass, the pressure head will drop below 75--100mm, and then the pressure head will gradually increase.

5. During the normal filtration process, avoid knocking and vibrating the filter plate. At the same time, the launder should be filled with aluminum water to avoid too much disturbance of the aluminum water.

6. After filtration, take out the filter plate in time and clean the filter box.

The ultimate goal of Hebei CangChen

Mar. 17, 2025

Contact Us

+86 158 3011 4065

Guoruiyuan Building, ShengLi North Street, Chang'An District, Shijiazhuang City, Hebei Province, China.

Navigation

Navigation