Oct. 29, 2024

Firstly, aluminum is exposed to the furnace atmosphere in a molten or semi-molten state in the smelting process. It is very easy to oxidize, easy to react with water vapor and absorb hydrogen, easy to form various forms of non-metallic slag (such as furnace lining debris, chloride, carbide in flux, etc.) and coarse metal intercompound particles and so on.

Secondly,non-aluminum impurities are carried in during the process circulation by some of waste materials maked up the charging material.

Because the waste is coming from the process waste and scrap during each process in factory and the waste outside the factory, so, the composition is complex due to different way as well as the quality is poor.

These impurities often make the billet produced bubbles and inclusions, which seriously affect the purity of the metal melt, thus further affect the processing properties, mechanical properties, corrosion resistance and the appearance quality of the product.

Our fiberglass filter mesh are produced to remove effectively impurities, reduce turbulence and eliminate air bubbles, thereby improving the quality of castings and reducing costs.

Widely used in automobile and motorcycle wheels, cylinder pistons, aluminum rods, aluminum materials, aluminum ingots, aluminum plates and precision casting of all types of aluminum alloy casting.

Also, does not pollute the aluminum liquid and affect the chemical properties of the metal.

Therefore, aluminum waste containing the filter mesh, aluminum liquid from sprue and the riser can be directly returned to the furnace for remelting, greatly reducing costs.

Application type:

● Filter cloth in roll (white & brown, without/with coating) : It can be fixed in the aluminum liquid flow tank, used for aluminum ingot, aluminum rod, aluminum strip and other continuous casting workshop to purify aluminum liquid.

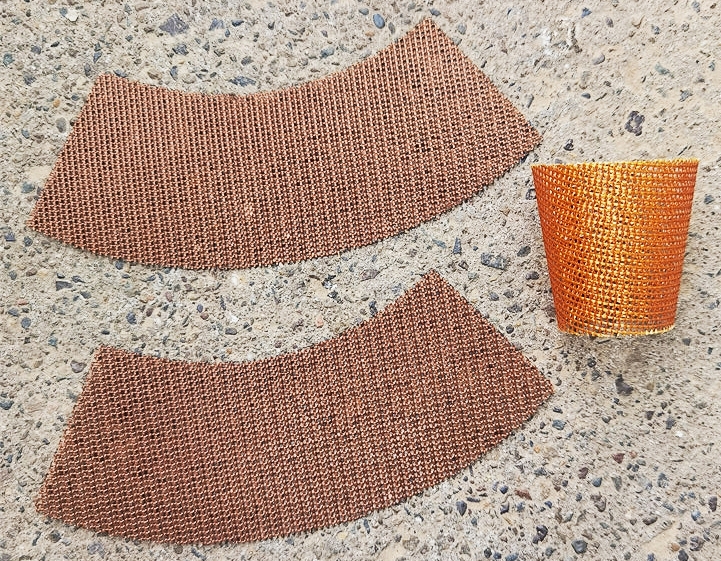

● Cutting mesh (brown, coated with resin): Square, round, fan and other heteroideus mesh cutted just according to client’s requirements. Used for filtering aluminum castings and placed in the gating system.

● Cylinder, cap and other special shapes (brown or black, coated with resin or carbonized): used for low pressure casting, such as aluminum alloy wheels, engine cylinder head and so on.

● Smokeless (black carbonization treatment): no combustion, smokeless, low gas output during the filtration process, for high quality requirements of casting production, such as aluminum alloy piston.

Fiberglass Cap Filter For Car Wheel Hub And Pistons

Apr. 14, 2025

Contact Us

+86 158 3011 4065

Guoruiyuan Building, ShengLi North Street, Chang'An District, Shijiazhuang City, Hebei Province, China.

Navigation

Navigation