Oct. 01, 2024

For metal liquid, like steel, iron, copper and aluminium casting factories, until now, Stainless wire mesh filters are used for filtration.

But due to high temperature and material of metal filters, there will be chemical reaction during whole filtration process. Then it will result in bad quality metallic solution, what's more, it will affect casting quality.

So, more and more foundry plants start to find better filters to instead of Stainless wire mesh filters.

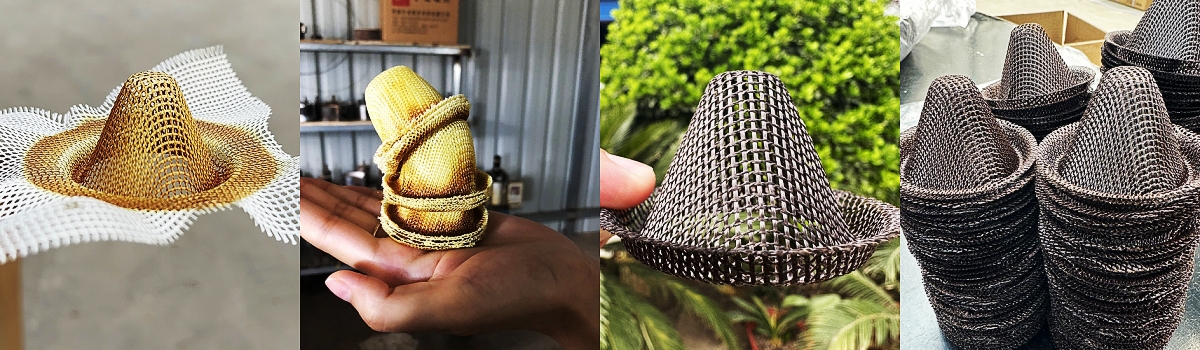

Fiberglass cap-style filter is woven by special high-twist & high-strength alkali-free fiberglass yarn, coated with special resin and produced by special post-treatment. The maximum temperature resistance can reach 900 ℃.

Widely used in automobile and motorcycle wheels, cylinder pistons, aluminum rods, aluminum materials, aluminum ingots, aluminum plates and precision casting of all types of aluminum alloy casting.

Why it is chosen by more and more clients?

First of all, it is imperative to reduce the waste of resources in the metal industry. It can effectively reduce more than half of the slag, impurities caused by the waste phenomenon. This is also the main reason for the wide use of filters, also the main trend.

Secondly, it can effectively remove non-metallic inclusions in liquid metal, which is also a big use of cap filter. It can significantly improve the casting structure and mechanical properties, so that the casting quality is higher, better quality, reduce the rejection rate, reduce tool wear.

Thirdly, Cap Casting filter is not only used to reduce casting porosity, but also can effectively reduce casting surface defects and increase process yield. It can effectively screen and adsorb small pre-slag, so that the quality of metal castings is better, the performance is better, to create high-quality castings.

● Does not pollute the aluminum liquid,

● Does not affect the chemical properties of the metal,

● Aluminum waste containing the filter mesh, aluminum liquid from sprue and the riser can be directly returned to the furnace for remelting, greatly reducing costs.

● Effectively remove impurities,

● Reduce turbulence and eliminate air bubbles,

● Improving the quality of castings and reducing costs,

Our Service:

● Our Service: Individual custom-made products.

● Materials: Client's drawing and samples.

● Mould: Produced by us.

● Shapes: The shapes of filter screen products are: rectangle, square, circle, ellipse, ring, rectangle, hat, waist, and special-shaped.

● Types: single-layer, double-layer, and multi-layer.

● Produce process: The different shapes of the filter mesh, and the technology is also different.

Fiberglass Cap Filter For Car Wheel Hub And Pistons

Apr. 14, 2025

Contact Us

+86 158 3011 4065

Guoruiyuan Building, ShengLi North Street, Chang'An District, Shijiazhuang City, Hebei Province, China.

Navigation

Navigation