Apr. 14, 2025

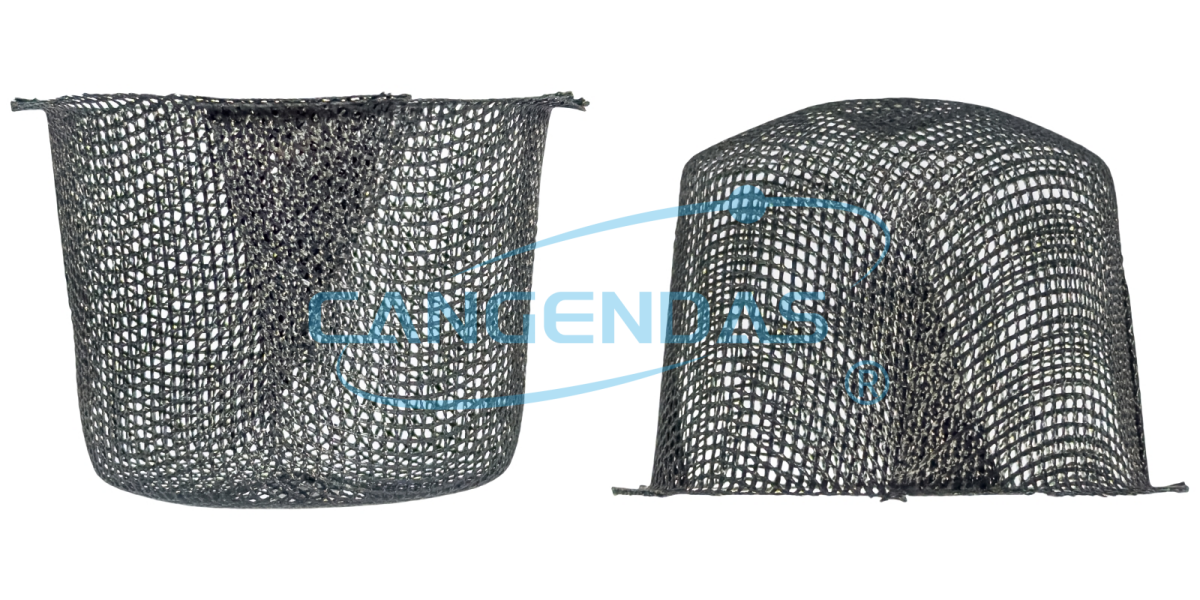

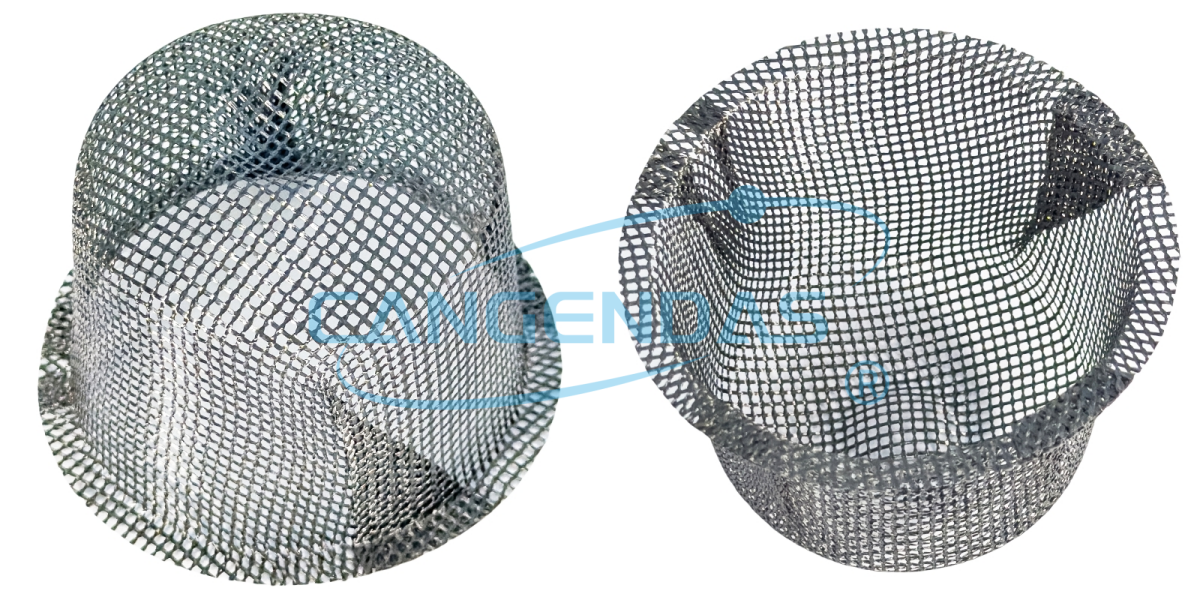

The main applications of Fiberglass Cap Filter are to filter molten aluminum, remove bubbles and inclusions in the metal melt, and improve the yield of castings.

The usage of cap type fiberglass filter mesh can effectively remove liquid metal and non-metallic inclusions, improve the structure and mechanical properties of castings, improve the high quality standards of precision castings production and reduce the rate of casting defects. It can also reduce tool wear during machining and significantly improve efficiency. In addition, it can reduce porosity in the casting, reduce surface defects and reduce casting and filling lines, significantly increasing the process yield, which is much better than high silicon screen casting filters and cast filter products with straight holes.

It is made of special Fiberglass yarn and processed through special techniques. It can withstand temperatures above 850℃ and it is an effective filter medium for aluminum liquid.

The Fiberglass Cap Filter is widely used in the casting processes of materials such as: automotive and motorcycle wheel hubs, cylinder pistons, aluminum rods, aluminum ingots, aluminum plates, and various aluminum alloy parts.

Cap type fiberglass filter mesh is usually a network structure, which is a non-metallic liquid metal purification device with the required mesh opening. Its porosity is higher, the slag collection surface area is larger, and it can reduce the the Reynolds number of the mesh metal surface flowing through the cast filter, then it can make the filler be more stable and reduce the production of secondary oxidation slag in the mold.

It can remove bubbles, inclusions, and other harmful impurities in the metal melt, thereby eliminating problems such as air eyes, slag eyes, and sand eyes in castings and improving the yield of castings.

Furthermore, Fiberglass Cap Filter also possesses the characteristics of high-temperature resistance, acid and alkali resistance, corrosion resistance, and wear resistance. It is applicable for screening and filtering in various acid and alkali environments. Its excellent performance in anti-corrosion and oxidation resistance, as well as wear resistance, along with its long service life, make it widely used in various industries.

Hebei CangChen, a professional manufacturer of foundry filtration products, specializes in research & development, production, sales, service and solutions. We are the recognized leader in the development and production of casting filters at home and abroad, and possesses the excellent innovation and customization capabilities in filter manufacturing technology.

With the development of our business and in order to provide better services to our global customers, we began to apply, register and export "CANGENDAS" as our trademark in early 2024, aiming to help customers distinguish goods or services from different manufacturers or operators through its unique logo for easy selection and comparison.

● Smokeless & Odorless & Flameless Fiberglass Filter Mesh

● High silica fiberglass filter mesh

● Other special-shaped mesh filters

● Individual custom-made products

● Materials: Client's drawing and samples

● Mould: Produced by us

● Shapes: Rectangle, square, circle, ellipse, ring, rectangle, hat, waist, and special-shaped

● Types: single-layer, double-layer, and multi-layer

● Produce process: The different shapes of the filter mesh and the technology is also different

Fiberglass Cap Filter For Car Wheel Hub And Pistons

Apr. 14, 2025

Contact Us

+86 158 3011 4065

Guoruiyuan Building, ShengLi North Street, Chang'An District, Shijiazhuang City, Hebei Province, China.

Navigation

Navigation