Jan. 24, 2025

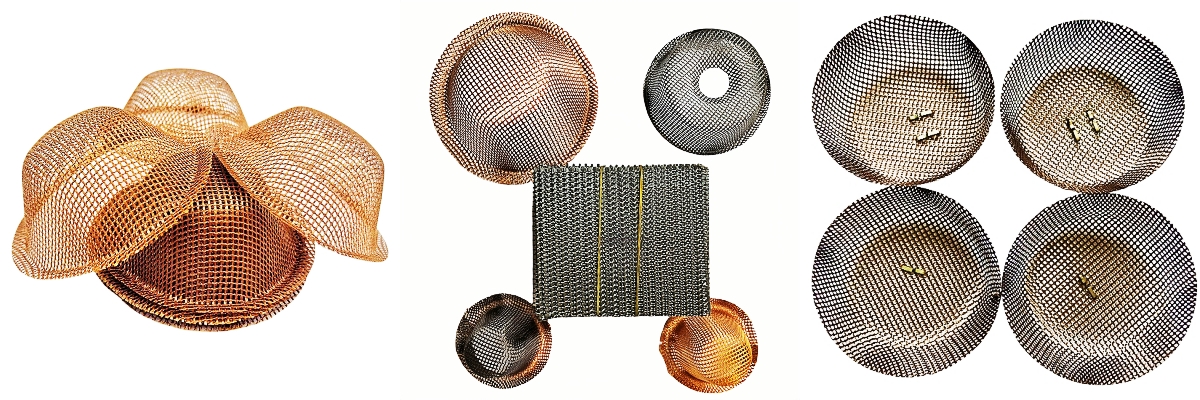

Fiberglass cap-style filter is thermal formed by customized mould, cut the sides, coated with special resin, carbonized by high temperature and produced by special post-treatment.

This filter is a sophisticated product, each step must be controlled with accurate technology.

The cap fiberglass filter mesh cost is cheap, easy to use, it can improve the mechanical properties of castings without changing the metal composition, improve the production quality of castings.

At the same time, it is resistant to high temperature and ablative properties, and it can operate at temperatures of about 850°C.

1. Improve the graphite form in the casting to reduce the graphite size, thinner thickness and slightly curved shape.

2. Change the machining performance of castings and improve the processing speed.

3. Stabilize the metal melt and flow rate, completely protect the cavity and prevent the metal melt from damaging the cavity and causing sand clamping defects in the casting!

4. Prevent the flow of metal melt too fast, resulting in sand expansion, cavity drop, burrs and uneven surface!

5. Eliminate bubbles to increase the density and hardness of the casting and the tensile strength at room temperature.

6. Efficient removal of impurities, reduce casting inclusions, air, slag holes and trachoma defects, greatly reducing the defective rate!

7. The trial production range includes cast steel, cast iron, cast copper, cast aluminum, sand casting, bright casting, wax casting and lost casting, water glass and resin sand casting, which greatly improve the production of castings and reduce foundry costs.

Firstly, Cap type fiberglass filter mesh is usually a network structure, which is a non-metallic liquid metal purification device with the required mesh opening. Its porosity is higher, the slag collection surface area is larger, and it can reduce the the Reynolds number of the mesh metal surface flowing through the cast filter, then it can make the filler be more stable and reduce the production of secondary oxidation slag in the mold.

Secondly, The usage of cap type fiberglass filter mesh can effectively remove liquid metal and non-metallic inclusions, improve the structure and mechanical properties of castings, improve the high quality standards of precision castings production and reduce the rate of casting defects. It can also reduce tool wear during machining and significantly improve efficiency. In addition, it can reduce porosity in the casting, reduce surface defects and reduce casting and filling lines, significantly increasing the process yield, which is much better than high silicon screen casting filters and cast filter products with straight holes.

Thirdly, For some castings that require high surface quality and good densification, in order to prevent inclusions and improve the internal quality of the castings, it is very necessary to install a cap type fiberglass filter mesh in the gate system. Especially in the field of small and medium-sized castings, such as: automobiles, high-speed railways, machine tools and hydraulic parts, the purification effect of the cap filter mesh has been widely recognized by most foundry workers.

Contact Us

+86 158 3011 4065

Guoruiyuan Building, ShengLi North Street, Chang'An District, Shijiazhuang City, Hebei Province, China.

Navigation

Navigation