Apr. 12, 2023

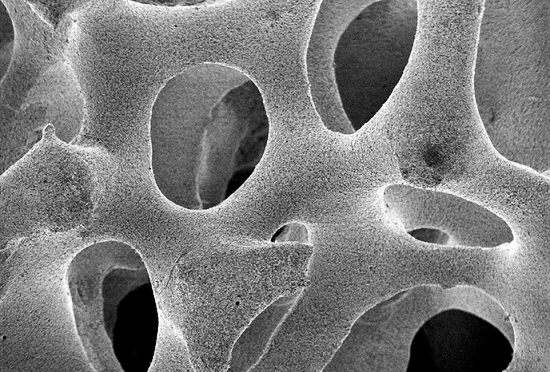

Silicon carbide ceramic foam filter adopts German imported polyurethane foam sponge as the carrier, the slurry which mainly contains silicon carbide slurry is extruded into the foam sponge, and then extrude slurry, the remaining slurry coated around the foam fiber during by drying, roasting and sintering at high temperature, polyurethane thermal decomposition, leaving the foam like ceramic products, namely, silicon carbide foam ceramic filter.

We, Hebei Cangchen, has exported SIC Ceramic Foam Filters with 200mm x 22mm 25ppi To Our European Client. Both of us has achieved a common goal, that is, they will purchase 200,000 pcs of this size in 2023 and we must ensure the best quality and delivery time.

SIC ceramic foam filter with foam sponge three-dimensional mesh interworking structure can make the metal liquid reflect the rectification, mechanical screening, filter cake, adsorption filtration mechanism to effectively improve the purity of metal liquid, reduce scrap rate, reduce machining losses so as to improve production efficiency and reduce production costs.

SIC Ceramic Foam Filters can effectively remove oxidized inclusions and other non-metallic inclusions by blocking and capturing adsorption of molten copper or molten iron using three-dimensional structure. No matter gray iron, ductile iron, shaft body, cylinder block or complex large pieces, hardware parts after filtering, the quality will be very stable and satisfactory results.

Main Functions:

● Purify metal molten liquid

● Simplify pouring system

● Improve the casting metallographic structure

● Improve casting qualification rate

● Reduce inclusions in castings

● Reduce the reoxidation defects of castings internal

● Reduce surface defects of castings after machining

The ultimate goal of Hebei CangChen

Mar. 17, 2025

Contact Us

+86 158 3011 4065

Guoruiyuan Building, ShengLi North Street, Chang'An District, Shijiazhuang City, Hebei Province, China.

Navigation

Navigation