Jan. 19, 2025

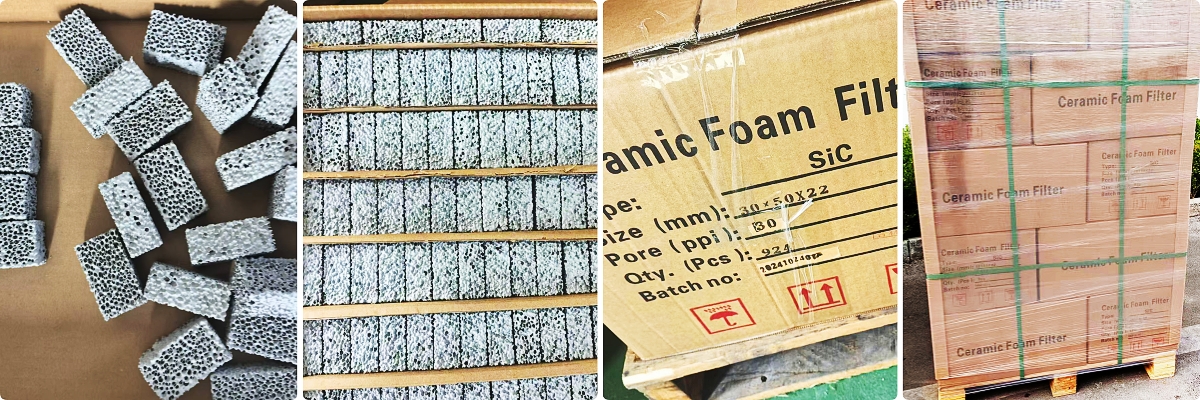

SIC Ceramic foam filters are suitable for the casting of all copper alloys and cast iron because of its high strength, resistance to high temperature impact force and chemical corrosion and operating temperature 1530°C.

SIC Ceramic foam filters can significantly improve the quality of cast iron parts and reduce the rejection rate. They can also be used in continuous casting and rolling processes and can be manufactured to different sizes and thicknesses depending on the runner and pouring weight.

It is also suitable for copper, bronze, brass and other copper alloys, reduce the turbulence of copper liquid and purify the molten copper liquid.

What is especially valuable is that the life of copper castings purified by filtration is significantly prolonged in high requirements or harsh environment, such as: Marine turbine and chemical parts, and it also has good effect on the cast copper parts with surface polishing requirements.

It also plays an important role in the traditional copper industry, electrical and electronic copper industry and continuous casting and rolling technology.

Due to copper and its alloys, including zinc alloys, have greater specific gravity and produce greater thermal shock during pouring, the use of silicon carbide foam ceramic filters in the copper casting process generally has strict sizes requirements.

Contact Us

+86 158 3011 4065

Guoruiyuan Building, ShengLi North Street, Chang'An District, Shijiazhuang City, Hebei Province, China.

Navigation

Navigation