Dec. 01, 2023

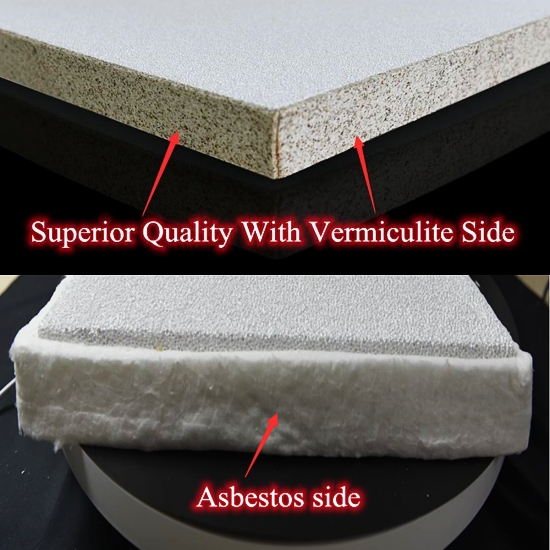

Alumina Ceramic Foam Filter Plate is made of organic foam sponge with three-dimensional network structure and connected pores is used as the carrier, which is infiltrated into the special ceramic slurry with thixotropy, and a special rolling process is adopted to make the ceramic slurry evenly spread on the skeleton of the carrier, and then finished by roasting at high temperature after drying curing.

Application:

● In order to meet the increasing quality requirements of aluminum castings, the use of alumina ceramic foam filters (plates) is becoming more and more important.

● Aluminium Ceramic Foam Filter Plate is suitable for the temperature of 1000 ℃, used for the filtration and purification of aluminum and alloy solutions.

● Filters are also widely used in ordinary sand casting, such as wet mold casting, and fixed mold casting, such as automotive aluminum parts casting.

Functions:

1. Filtration makes the flow of molten aluminum more orderly and relatively calm;

2. Solid slag in the molten metal is effectively removed, and the quality of castings is rapidly improved.

3. Effectively removes the solid inclusions in the Peirong metal, so the aluminum alloy can be smoothly forged, aluminum foil manufacturing extrusion processing and other processes to obtain high-quality products.

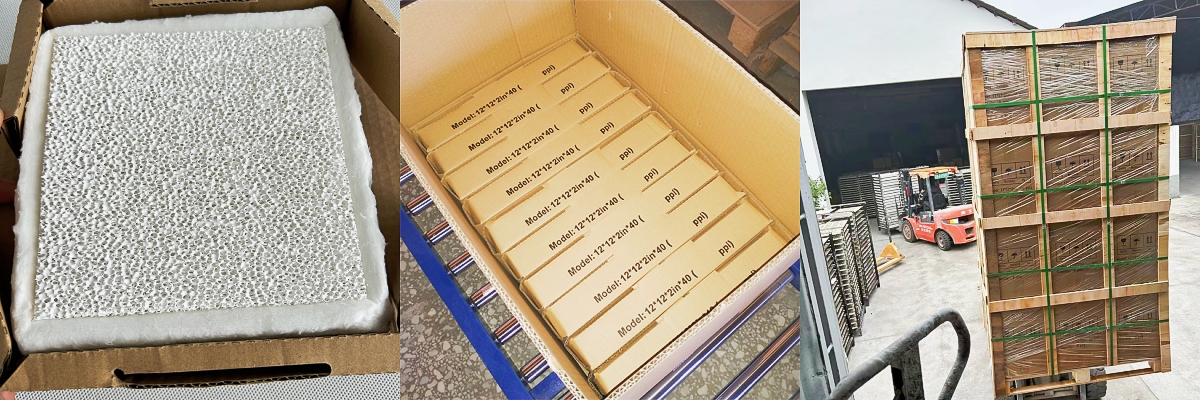

Export:

Today, Four pallets of Alumina Ceramic Foam Filter Plate are exported to Vietnam for aluminium filtration application.

Fiberglass Cap Filter For Car Wheel Hub And Pistons

Apr. 14, 2025

Contact Us

+86 158 3011 4065

Guoruiyuan Building, ShengLi North Street, Chang'An District, Shijiazhuang City, Hebei Province, China.

Navigation

Navigation