Dec. 10, 2023

Nowdyas, fiberglass filter mesh is adopted to filter and purify metal liquids by casting industries.

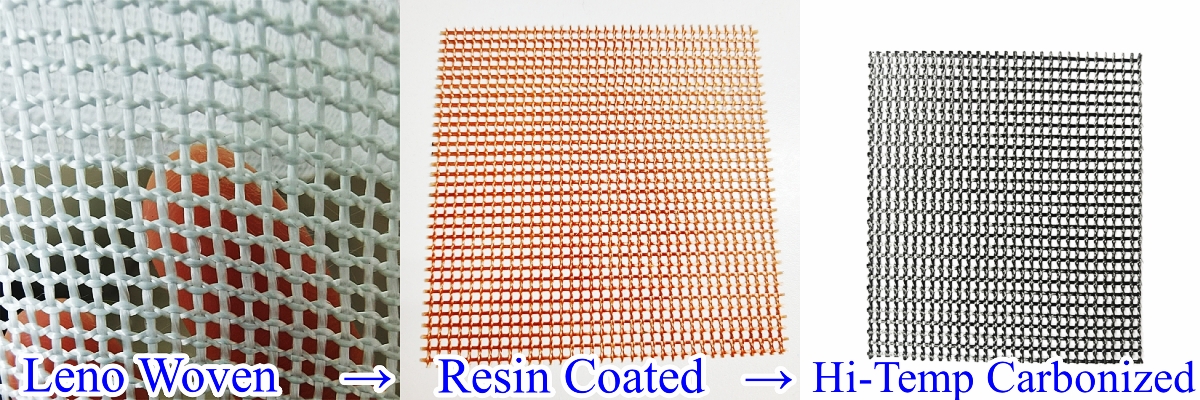

Fiberglass filter mesh is made of various materials fiberglass cloth by impregnating resin and other bonding materials.

The main function is to block macroscopic inclusions into the cavity and slightly adsorb small inclusions.

Non-alkali mesh is generally used for casting aluminum, high silicon oxygen mesh is usually used for casting iron and steel.

The mechanism of filtering metal liquid by Fiberglass filter mesh:

● Rectifier mechanism: the filter is placed in the pouring process, the metal liquid is increased the resistance during pouring, changes the flow state, and makes the metal liquid slowly flow into the cast cavity, which is not easy to bring eddy current, the filling is stable, the secondary oxidation and slag inclusion are reduced, which is conducive to the floating of inclusions and the slag blocking function of the pouring system.

● Mechanical filtration: there are a large number of inclusions in liquid metal, slag and other large impurities, through the selection of suitable aperture filter to filter out inclusions larger than the aperture size by mechanical methods.

● Double filtration: During the mechanical filtration, the filter net captures many inclusions larger than the aperture and with the increase of the number of inclusions, the double filtration is formed at the entrance of the filter screen. The double filtration make the liquid metal flow fine and have the function of filtering. The liquid metal can be filtered twice.

● Adsorption: The filter mesh has a large specific surface area, the liquid metal flow through the filter is divided into a small liquid flow unit, then the contact area of the liquid metal and the filter medium is increased. The chemical reaction between harmful elements and oxides in the metal melt and the filter surface is adsorbed on the filter mesh surface.

Main Functions:

● The the impurities in castings are reduced by half when adopt filter mesh and the scrap rate is reduced.

● Filter out impurities, reduce the adverse effects of impurities on the microstructure and properties of casting alloy and improve the material properties of casting.

● The machining performance of castings is improved.

● Improve the yield of process.

● Improve the surface quality of castings because of the impurities are filtered out and the secondary oxidation is reduced.

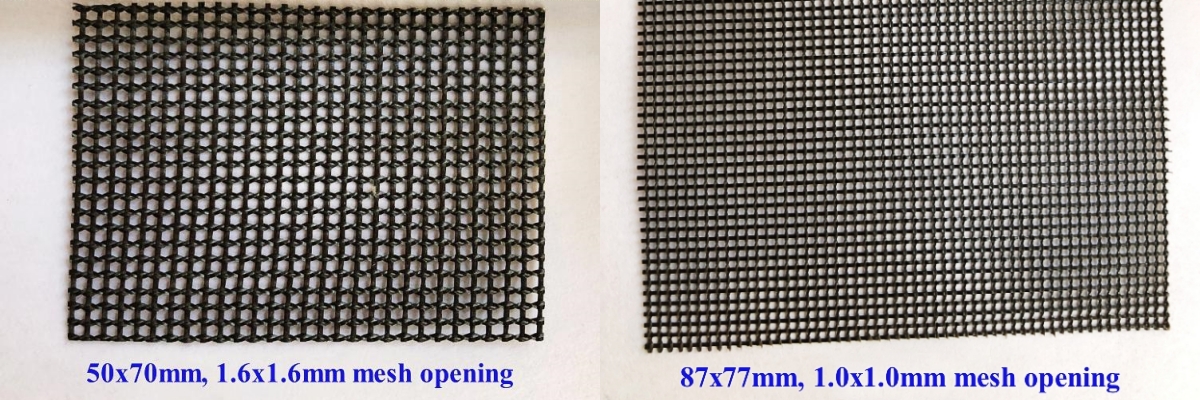

Today, we exported two models: 50mm X 70mm, 1.6mm X 1.6mm mesh opening and 87mm X 77mm, 1.0mm X 1.0mm mesh opening to our Hungary client, for filtration of aluminium liquid.

Both of two models are Smokeless (black carbonization treatment): no combustion, smokeless, low gas output during the filtration process, for high quality requirements of casting production, such as aluminum alloy piston.

Fiberglass Cap Filter For Car Wheel Hub And Pistons

Apr. 14, 2025

Contact Us

+86 158 3011 4065

Guoruiyuan Building, ShengLi North Street, Chang'An District, Shijiazhuang City, Hebei Province, China.

Navigation

Navigation