Jul. 15, 2022

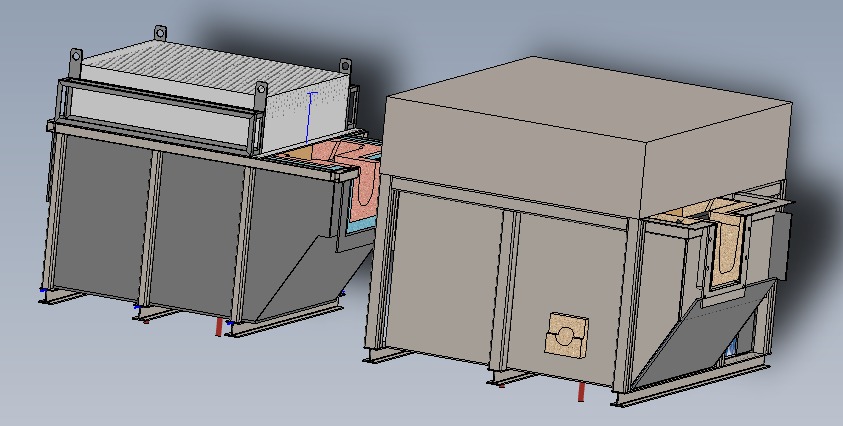

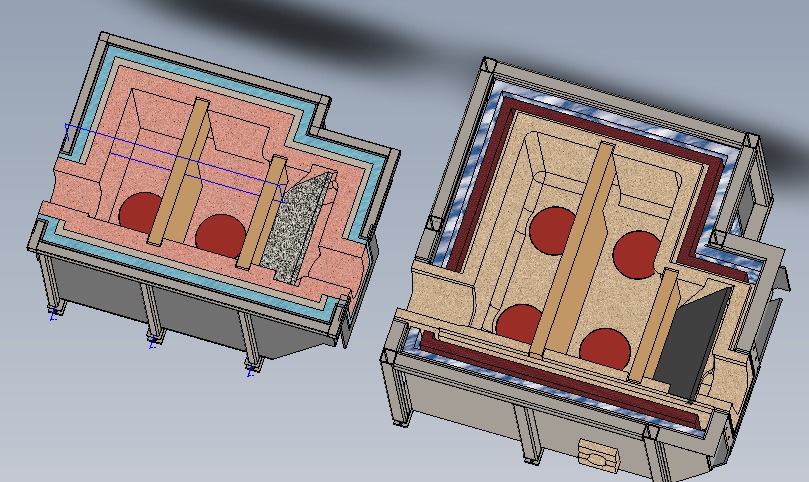

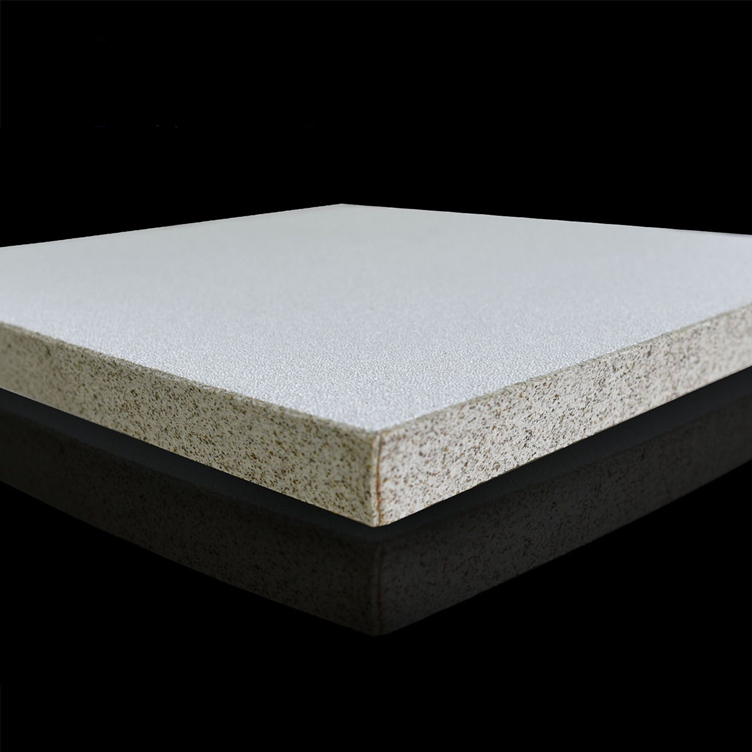

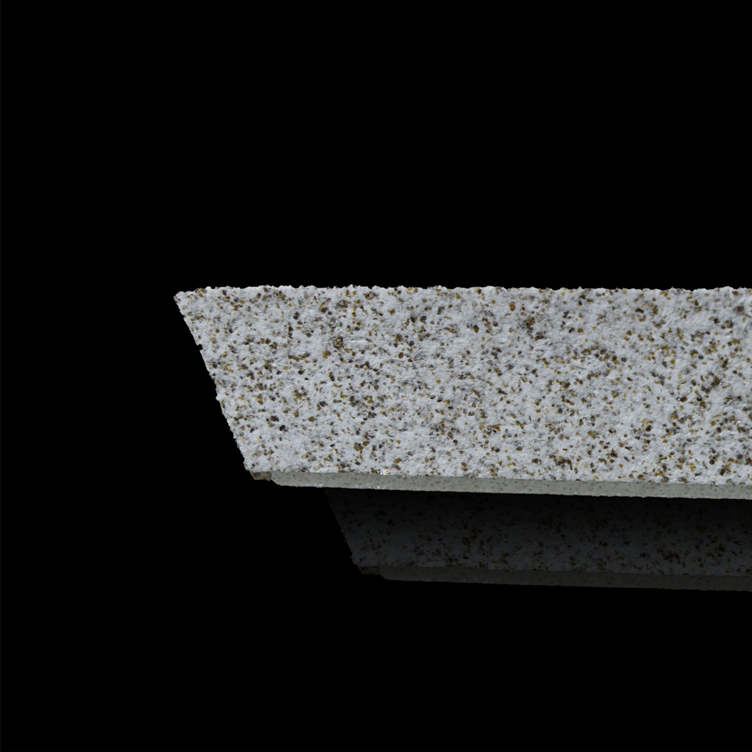

Ceramic foam filter is just developed as a new type molten metal filters to decrease casting flaw and also as a catalyst carrier for Air Treatment in recent years, play a vital role in the metal casting and air treatment, where they are used to filter out impurities in molten metal to improve the quality and performance of the end product or decompose organic pollutants into pollution-free water (H2O) and carbon dioxide (CO2) to meet high environmental requirements.

Cangchen high-temperature resistant foam filter that does not contaminate the melt and does not result in degradation of desirable characteristics in the final metal product.

The usage of filtration process is mainly based on the following considerations:

1. Filtration makes the flow of molten aluminum more orderly and relatively calm;

2. Solid slag in the molten metal is effectively removed, and quality of castings is rapidly improved.

The alumina foam ceramic filter product effectively removes the solid inclusions in the Peirong metal, so the aluminum alloy can be smoothly forged, aluminum foil manufacturing extrusion processing and other processes to obtain high-quality products.

Cangchen superior quality alumina ceramic foam filter:

Hebei Cangchen Company has obtained ISO Certificate, we will provide all clients the best quality products.

Contact Us

+86 158 3011 4065

Guoruiyuan Building, ShengLi North Street, Chang'An District, Shijiazhuang City, Hebei Province, China.

Navigation

Navigation