Feb. 17, 2025

The liquid aluminum in contact with the air is easy to be oxidized, resulting in impurities such as oxide skin. And the quality requirements of aluminum castings are also very high.

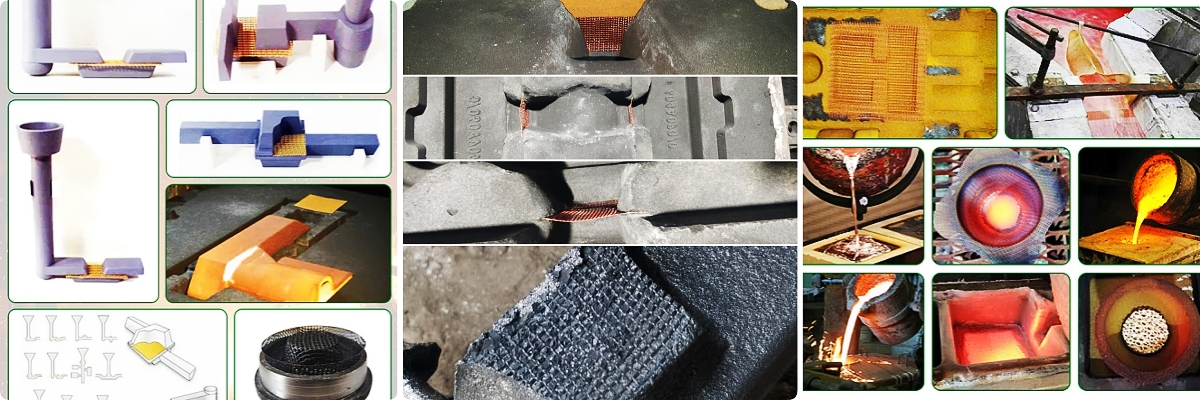

It can be a good solution to solve such problems that use fiberglass filter mesh.

Fiberglass Filter Cloth is weaved by alkali-free E-glass fiberglass yarn.

There are two types:

● One is white color and soft without any coating.

● The other is brown color with coating by special resin.

Fiberglass filter mesh is made of high-twist high-strength alkaline-free fiberglass yarn weaving through special treatment, the temperature can be up to 900℃, dedicated to aluminum liquid filtration, such as: used in automobile and motorcycle wheel, cylinder piston, aluminum rod, aluminum ingots, aluminum plate and aluminum alloy parts of the investment casting. It can effectively remove impurities, eliminate bubbles in aluminum liquid, slag, etc., thereby improving casting quality and reducing production costs.

Fiberglass filter mesh is suitable for all kinds of aluminum alloy casting, such as sand casting, mold, shell mold, drawing die, investment casting and other fields.

At the same time, fiberglass filter mesh does not pollute the aluminum liquid, does not affect the chemical properties of the metal, will not pollute the aluminum liquid, and reduce the cost.

● Cut mesh: (Brown, coated with resin coating): Square or round mesh, cut to size as required, for filtering aluminum castings and using in pouring systems.

● Special shapes such as caps: (Brown or black, coated with resin or carbonized): used for low-pressure casting, such as: aluminum alloy wheels, cylinder heads, etc.

● Smokeless: (Black carbonization): NO combustion, smokeless, small gas in the filtration process, suitable for casting aluminum alloy piston and other castings with high quality requirements.

In recent years, the quality requirements of various aluminum processing products are getting higher and higher.

To improve product quality, the first is to improve the castings quality.

The aluminum liquid purification process adopted in the past could not remove the suspended matter and non-metallic inclusions in the molten aluminum, so that the structure of the casting would be deteriorated.

But now, more and more foundry factories are choosing our fiberglass filter mesh to filter aluminum, which can effectively filter out the inclusions in liquid aluminum and achieve good results.

Usage Method:

1. First of all, Choose the placement position of fiberglass filter mesh:

There are three main placement positions:

● One is placed at the top of the sprue under the sprue cup,

● The second is placed at the lap of the cross sprue,

● The third is placed at the corner contact between the cross sprue and the inner sprue.

2. Place filter mesh on the parting surface:

There are two placing ways,

● One is horizontal placement, also can be said to be parallel placement, the filter is placed horizontally under the crossmouth cup or parting surface, the casting height should not exceed 20 cm, the metal liquid is washed at the intersection cup wall, not directly to the filter mesh;

● The other is vertical placement.

3. The filter mesh is placed on the top, and the bending surface should be kept upward and flattened from the center to the four sides. At the same time, the filter mesh can not have wrinkles.

4. After aluminum is melted in the smelter, it will be slagged and degassed until it meets the casting requirements, and then it can be out of smelter. The general temperature when coming out is 720℃~730℃. The qualified aluminum liquid is filtered through the flow tank and then poured into the semi-continuous casting crystallizer.

5. In order to ensure that the aluminum melt has sufficient fluidity, the temperature of the liquid aluminum is usually appropriately increased by 3℃ to 5℃ (compared with the unfiltered), and the temperature is generally controlled above 680℃, but it can not be too high.

6. The aluminum liquid should have a certain initial pressure to ensure that the aluminum melt smoothly passes through fiberglass filter mesh, and the initial pressure is 100 to 150 mm.

The ultimate goal of Hebei CangChen

Mar. 17, 2025

Contact Us

+86 158 3011 4065

Guoruiyuan Building, ShengLi North Street, Chang'An District, Shijiazhuang City, Hebei Province, China.

Navigation

Navigation