Mar. 24, 2023

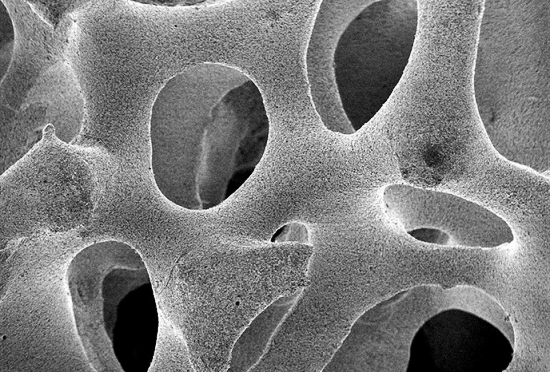

Silicon carbide ceramic foam filter adopts German imported polyurethane foam sponge as the carrier, the slurry which mainly contains silicon carbide slurry is extruded into the foam sponge, and then extrude slurry, the remaining slurry coated around the foam fiber during by drying, roasting and sintering at high temperature, polyurethane thermal decomposition, leaving the foam like ceramic products, namely, silicon carbide foam ceramic filter.

SIC ceramic foam filter with foam sponge three-dimensional mesh interworking structure can make the metal liquid reflect the rectification, mechanical screening, filter cake, adsorption filtration mechanism to effectively improve the purity of metal liquid, reduce scrap rate, reduce machining losses so as to improve production efficiency and reduce production costs.

Main Features:

● The chemical composition is stable, resistant to the corrosion of iron liquid and its alloys.

● Dense pores but not blocked, suitable for metal liquid flow, filter out impurities, particles, etc. in liquid.

● Porous structure, layer by layer to block impurities, prevent omission and reduce the probability of obstruction.

SIC ceramic foam filter has the characteristics of high strength, good thermal stability, large specific surface area and high dimensional accuracy.

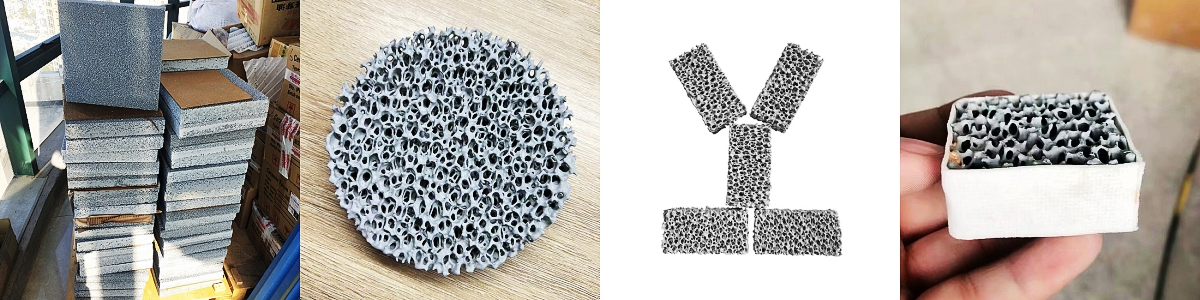

Mainly used for filtering and purifying nodular cast iron, gray cast iron, aluminum, copper and other alloy metal liquid filtration.

Main Functions:

● Reduce surface defects of castings after machining.Reduce internal reoxidation defects of castings.

● Reduce internal reoxidation defects of castings.

There are many shapes and ppi manufacturered in our factory.

● All shapes and ppi can be customized just according to your own drawings and requirements, any need, please leave us a message!

The ultimate goal of Hebei CangChen

Mar. 17, 2025

Contact Us

+86 158 3011 4065

Guoruiyuan Building, ShengLi North Street, Chang'An District, Shijiazhuang City, Hebei Province, China.

Navigation

Navigation