Feb. 28, 2024

Alumina foam ceramic is a kind of foam material made from high purity alumina. The foam ceramics have the characteristics of uniform porosity, high temperature resistance, heat shock resistance, wear resistance and chemical stability.

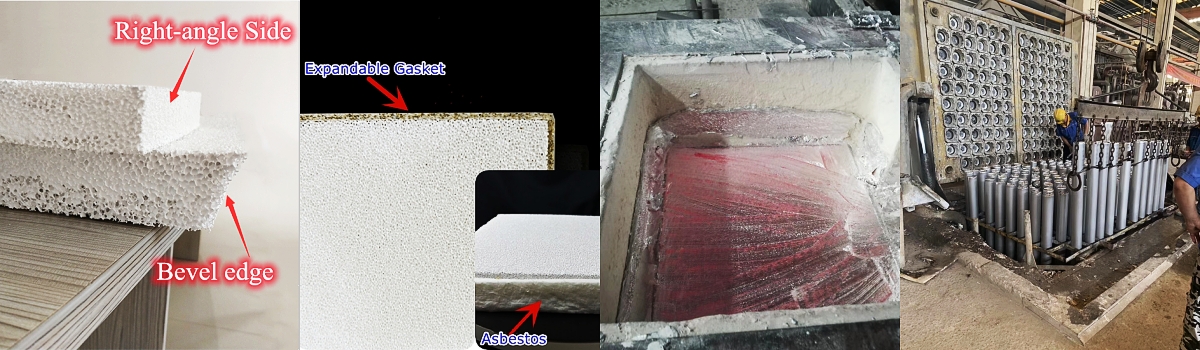

The organic foam sponge with three-dimensional network structure and connected pores is used as the carrier, which is infiltrated into the special ceramic slurry with thixotropy, and a special rolling process is adopted to make the ceramic slurry evenly spread on the skeleton of the carrier, and then finished by roasting at high temperature after drying curing.

Products are widely used in casting processing, water treatment, chemical industry, environmental protection and other industries.

It is the ideal liquid aluminum filter; Catalyst support, and good sound insulation, thermal insulation material. Product shapes, sizes, and voids PPI can be designed and manufactured on request.

| Model | Pore density (Number of holes on any 25.4mm length) |

| 10ppi | 7~13 |

| 20ppi | 17~23 |

| 30ppi | 27~33 |

| 40ppi | 37~43 |

| 50ppi | 47~53 |

| 60ppi | 57~63 |

| Item | Allowable variation | |||

| ≤381mm | 381mm~430mm | ≥430mm | ||

| Side length allowable variation(mm) | ±3 | ±4 | ±5 | |

| Diagonal line allowable variation(mm) | ±5 | ±7 | ±9 | |

| Plane clearance allowable variation(mm) | ≤3 | ≤6 | ||

| Thickness allowable variation(mm) | ±2 | |||

| Side rake allowable variation(°) | ±1° | |||

| Remarks:1. Diagonal deviation refers to the difference between the lengths of two diagonals on large surface of filter plate.2. The plane gap is to place the large surface of filter plate on platform, and measure the gap between filter plate and platform.3. Side bevel refers to the angle between side bevel and large surface.4. The filter plates involved in the table are all products with a theoretical thickness of 50mm and a side inclination angle of 17.5°. | ||||

1. Clean filter box

2. Gently put the filter plate into the filter box, and press the sealing gasket around the filter plate by hand to prevent the flow of molten aluminum.

3. Evenly preheat the filter box and filter plate to make it close to the temperature of the molten aluminum. Preheat to remove moisture and facilitate initial instant filtration. Preheating can be carried out using electric or gas heating. Under normal circumstances, it takes about 15--30 minutes.

4.Pay attention to the change of the aluminum hydraulic head during casting. The normal initial pressure head is 100-150mm. When the molten aluminum begins to pass, the pressure head will drop below 75--100mm, and then the pressure head will gradually increase.

5.During the normal filtration process, avoid knocking and vibrating the filter plate. At the same time, the launder should be filled with molten aluminum to avoid too much disturbance of the aluminum liquid.

6.After filtration, take out the filter plate in time and clean the filter box.

Fiberglass Cap Filter For Car Wheel Hub And Pistons

Apr. 14, 2025

Contact Us

+86 158 3011 4065

Guoruiyuan Building, ShengLi North Street, Chang'An District, Shijiazhuang City, Hebei Province, China.

Navigation

Navigation