Feb. 05, 2023

Alumina Ceramic Foam Filter Plate is produced with the organic foam sponge with three-dimensional network structure and connected pores is used as the carrier, which is infiltrated into the special ceramic slurry with thixotropy, and a special rolling process is adopted to make the ceramic slurry evenly spread on the skeleton of the carrier, and then finished by roasting at high temperature after drying curing.

Mainly used in the melting filtration of aluminum and aluminum alloys.

It can efficiently filter residues such as oxide slag, oxide scale, non-metallic inclusions and gate groove linings in molten aluminum, and solve the problem of aluminum and aluminum alloys being sensitive to internal defects.

The unique production process and detection method make the alumina filter plate with high opening rate, uniform pore structure and high surface strength.

Available in 7" to 26", mesh up to 60ppi filter plates.

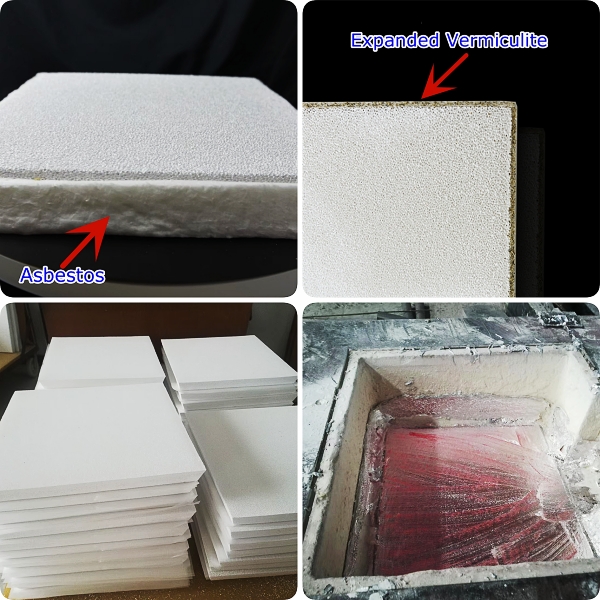

For two kinds alumina ceramic foam filters, one is asbestos hemming, the other is with expandable gasket.

Which one do you need?

Fiberglass Cap Filter For Car Wheel Hub And Pistons

Apr. 14, 2025

Contact Us

+86 158 3011 4065

Guoruiyuan Building, ShengLi North Street, Chang'An District, Shijiazhuang City, Hebei Province, China.

Navigation

Navigation