Mar. 11, 2025

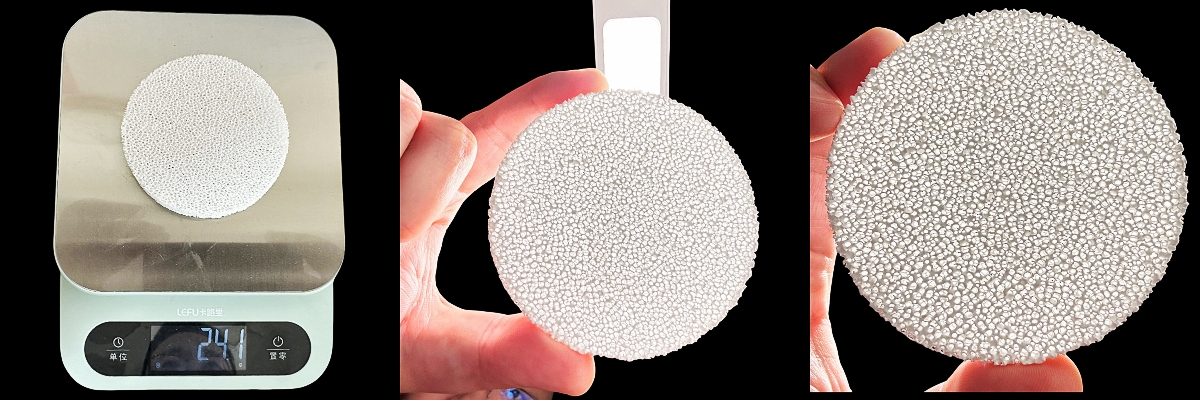

Alumina ceramic foam filters are mainly used in the purification process production of non-ferrous alloys such as aluminum and aluminum alloys, and can also be used as gas-solid, liquid-solid separation medium, catalyst substrate, ceramic burner, sound absorption, environmental protection, and other fields.

Mainly used for the filtration of molten aluminium and alloys in foundries and cast houses.

With the excellent resistance to attack and corrosion from molten aluminum, the filter can effectively remove inclusions, reduce trapped gas and provide laminar flow,and then the filtered metal is significantly cleaner. Cleaner metal results in higher-quality castings, less scrap, and fewer inclusion defects, all of which contribute to the bottom-line profit.

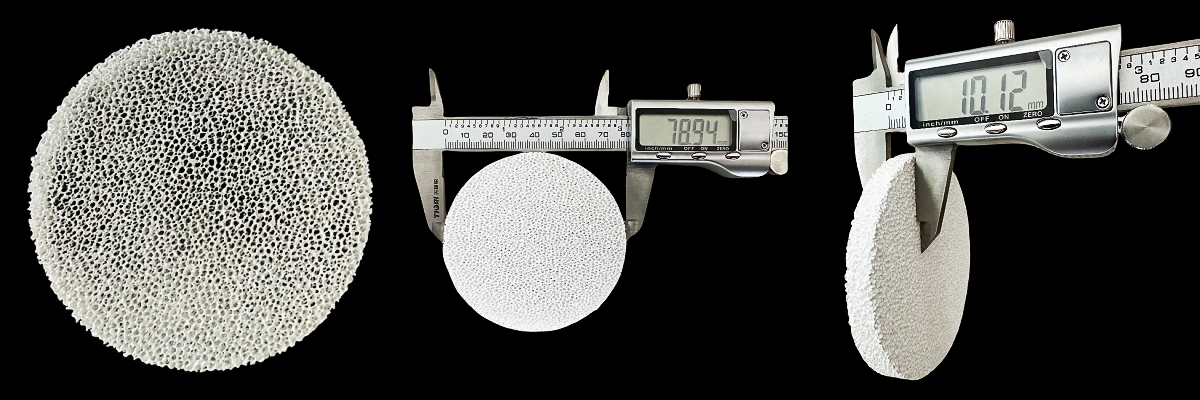

| Type | Alumina ceramic foam filter for aluminum and alloy |

| Main material | Al2O3, SIO2 |

| Al2O3 | ≥83% |

| Porosity | ≥85% |

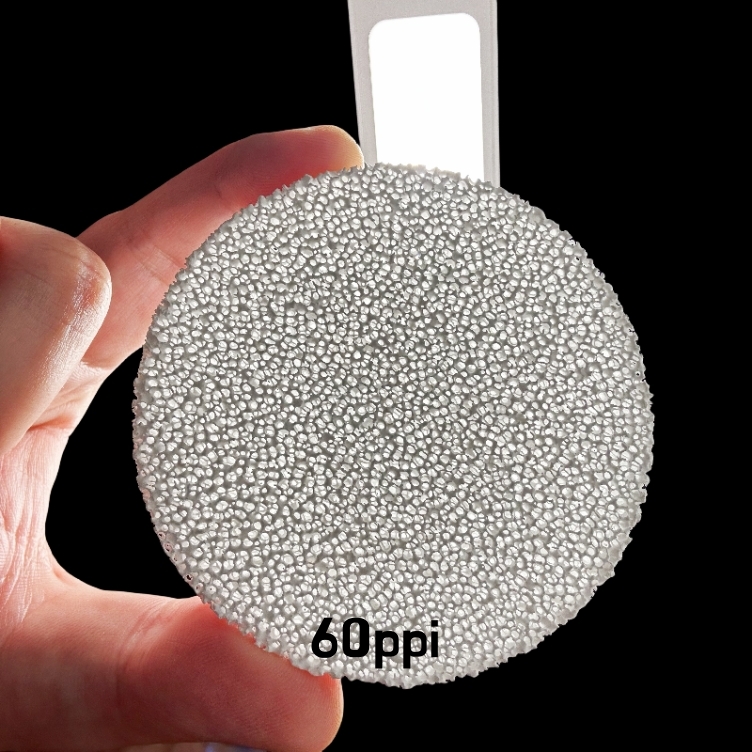

| PPI | 10/20/30/40/50/60(Customized) |

| Work Temperature | ≤1200℃ |

| Color | White |

| PPI | 10/20/30/40PPI(PPI=pores per inch) |

| Porosity | 80-90% |

| Compressive strength | ≥0.8Mpa(Room temperature) |

| Bulk Density | 0.4-0.5g/cm3 |

| Certificate | ISO9001:2015 |

| REACH & RoHS |

● Purify metal molten aluminum liquid

● Simplify pouring system

● Reduce inclusions in castings

● Reduce the reoxidation defects of castings internal

● Reduce surface defects of castings after machining

● Improve casting qualification rate

● Improve the casting metallographic structure

Fiberglass Cap Filter For Car Wheel Hub And Pistons

Apr. 14, 2025

Contact Us

+86 158 3011 4065

Guoruiyuan Building, ShengLi North Street, Chang'An District, Shijiazhuang City, Hebei Province, China.

Navigation

Navigation