Aug. 07, 2024

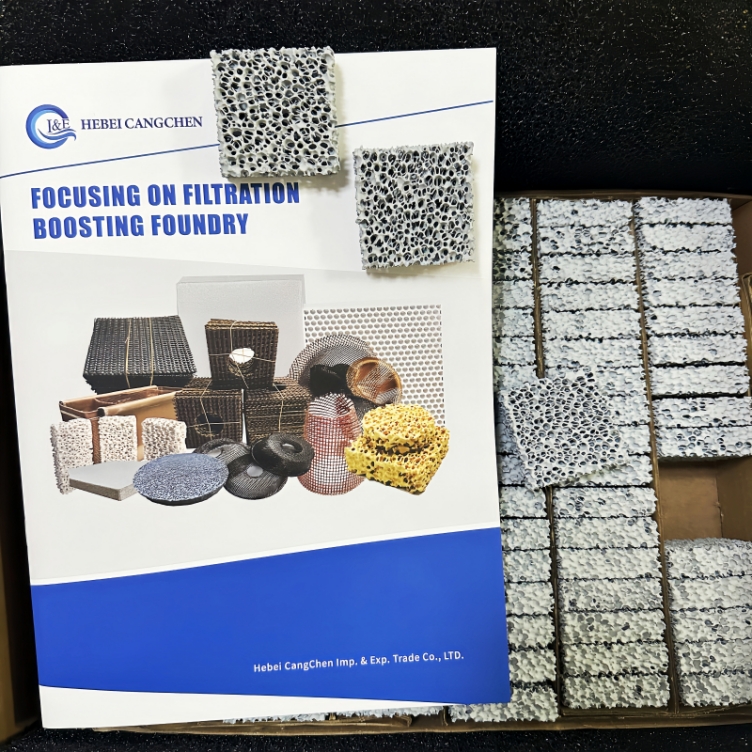

Silicon carbide ceramic foam filter adopts German imported polyurethane foam sponge as the carrier, the slurry which mainly contains silicon carbide is extruded into the foam sponge, and then extrude slurry, the remaining slurry coated around the foam fiber is dring, roasting and sintering at high temperature, polyurethane is decomposed by heat, foam shaped ceramic products are left, namely, silicon carbide foam ceramic filter.

SIC ceramic foam filter with foam sponge three-dimensional mesh interworking structure can make the metal liquid reflect the rectification, mechanical screening, filter cake, adsorption filtration mechanism to effectively improve the purity of metal liquid, reduce scrap rate, reduce machining losses so as to improve production efficiency and reduce production costs.

SIC ceramic foam filter has the characteristics of high strength, good thermal stability, large specific surface area and high dimensional accuracy.

SIC ceramic foam filter mainly used for filtering and purifying nodular cast iron, gray cast iron, aluminum, copper and other alloy metal liquid filtration.

Hebei Cangchen, a professional manufacturer of such SIC filters exported to internation markets with our own registered trademark: "CANGENDAS", but also OEM service will be provided for all customers from the world.

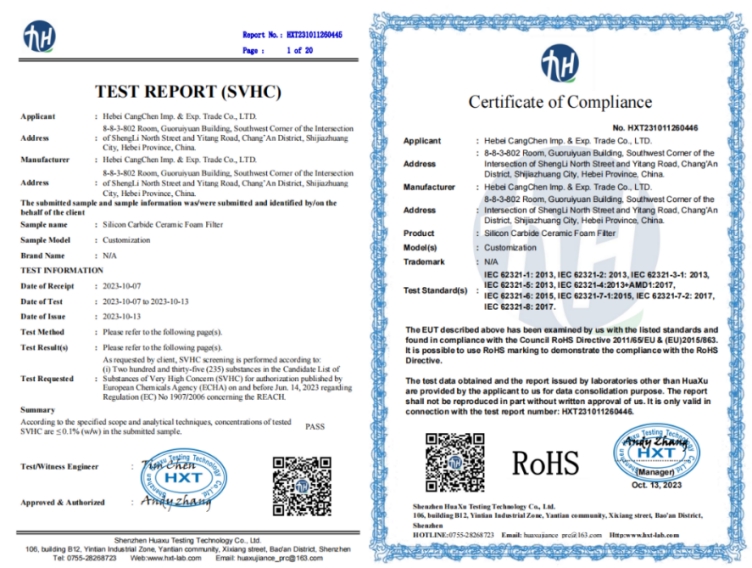

We are a professional factory with ISO certificate and our SIC filter has been certified by REACH&RoHS certificate.

50x50x15mm 10/20/30ppi Silicon carbide ceramic foam filter for India Market.

Excellent raw materials and advanced production technology ensure quite stable dimensional tolerance of our ceramic foam filters.

Fiberglass Cap Filter For Car Wheel Hub And Pistons

Apr. 14, 2025

Contact Us

+86 158 3011 4065

Guoruiyuan Building, ShengLi North Street, Chang'An District, Shijiazhuang City, Hebei Province, China.

Navigation

Navigation