Smokeless & Odorless & Flameless Fiberglass Casting Filter Mesh

● Weaved with special high-twist & high-strength alkali-free fiberglass yarn.

● Coated by special resin.

● Special post-treatment under high temperature carbonized.

● The Max. temperature resistance can be reached 900 ℃.

● Smokeless & Odorless & Flameless during whole filtration process.

Widely used in automobile and motorcycle wheels, cylinder pistons, aluminum rods, aluminum materials, aluminum ingots, aluminum plates and precision casting of all types of aluminum alloy casting.

● Effectively remove impurities, reduce turbulence and eliminate air bubbles, thereby improve the quality of castings and reduce cost.

● Does not pollute the aluminum liquid and affect the chemical properties of the metal.

● Aluminum waste containing the filter mesh, aluminum liquid from sprue and the riser can be directly returned to the furnace for remelting, greatly reducing cost.

Parameter

CangChen Smokeless Odorless Fiberglass Casting Filter Mesh is a state-of-the-art solution designed for high-temperature metal filtration, ensuring superior performance in aluminum casting processes. Our product, fiberglass filteration mesh and ceramic foam filter, stands as a testament to our expertise in producing reliable, innovative filtering materials.

Crafted using special high-twist, high-strength alkali-free fiberglass with advanced post-treatment, our Smokeless Odorless Fiberglass Casting Filter Mesh exhibits exceptional properties including zero shrinkage, high stiffness, and resistance to temperatures up to 900 ℃. This product is fireless, produces no black ashes, is odourless, non-toxic with VOC-free composition, and remains mechanically robust even after prolonged use.

Our Smokeless Odorless Fiberglass Casting Filter Mesh not only improves the quality of aluminum castings by effectively filtering out slag, bubbles, and inclusions but also supports environmental sustainability through the recyclability of filtered aluminum. With excellent chemical stability, resistance to metal melt erosion, and consistent performance, our product offers a cost-effective, durable solution for precision casting filtration.

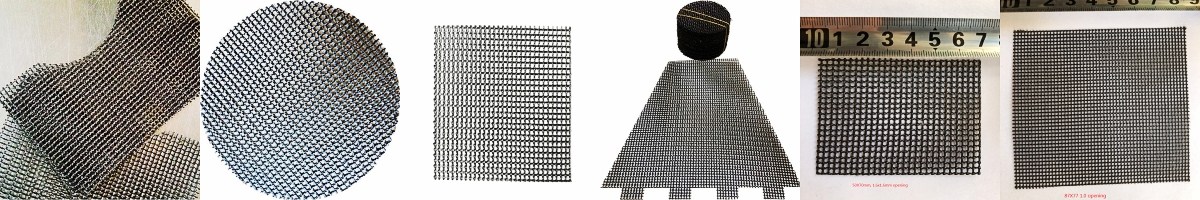

There are two types for fiberglass filter cloth:

● One is white color and soft without any coating.

● The other is brown color with coating by special resin.

Application type:

Designed as a Fiberglass Filter for Aluminum, our Smokeless Odorless Fiberglass Casting Filter Mesh is ideal for various filtration needs in metal casting. It is used as a filter cloth in roll for continuous casting workshops, as a cutting mesh for customized shapes in gating systems, and in special forms like cylinders or caps for low-pressure casting applications. These versatile applications help effectively remove impurities, reduce turbulence, and eliminate air bubbles in molten aluminum.

● Filter cloth in roll (white & brown, without/with coating): It can be fixed in the aluminum liquid flow tank, used for aluminum ingot, aluminum rod, aluminum strip and other continuous casting workshop to purify aluminum liquid.

● Cutting mesh (brown, coated with resin): Square, round, fan and other heteroideus mesh cutted just according to client’s requirements. Used for filtering aluminum castings and placed in the gating system.

● Cylinder, cap and other special shapes (brown or black, coated with resin or carbonized): used for low pressure casting, such as aluminum alloy wheels, engine cylinder head and so on.

● Smokeless (black carbonization treatment): no combustion, smokeless, low gas output during the filtration process, for high quality requirements of casting production, such as aluminum alloy piston.

Technical Data Sheet:

| Type | Fiberglass Filter Cloth in roll for aluminum filtration | |

| Yarn type | E-glass fiberglass | |

| Weave type | Leno & plain | |

| Width/roll | 0.9m/1.0m ± 1cm and customized | |

| Length/roll | 100m/150m/200m and customized | |

| Thickness | 0.35-0.6mm | |

| Weight | 150-350g/m2 | |

| Mesh opening | 0.8*0.8/1.0*1.0/1.2*1.2/1.5*1.5/2.0*2.0/2.5*2.5mm and customized | |

| Coating | No Coating | White color and soft fabric |

| Coating with special resin | Brown color and hardness fabric | |

| Work Temperature | 700-900℃ | |

| Softening Temperature | 900℃ | |

| Continuous Working Hours | <20Min.(700-800℃) | |

| Gas Emit | ≤30cm 3/g | |

| Loss on ignition | ≤3% | |

| SiO2 | 58%-65% | |

| Certificate | SDS | |

| ISO9001:2015 | ||

New patented product "Smokeless & Odorless & Flameless Fiberglass Filtration Mesh"

This kind of filter will gradually replaces similar products (Especially metal filters type) because of the following obviuos features:

● Carbonized by High Temperature

● Coated with special resin

● Smokeless & Odorless & Flameless

● Effectively remove impurities, reduce turbulence and eliminate air bubbles from molten aluminium

● Improving the quality of castings and reducing costs

● The aluminium filtered by this mesh can be recycled again

● It is environment-friendly products

● All shapes can be customized according to clients' requirements

Compared with other types of filters, fiberglass casting filter is cheap, easy to use, does not change the metal composition of the casting, has good slag filtering effect and low gas generation.

In addition, it also has high temperature resistance, ablation resistance, good chemical stability, resistance to metal melt erosion and good steel strength.

The application range is of aluminum, aluminum ingots, aluminum plates and aluminum alloy parts and other precision casting filtration. It can effectively remove bubbles, slag inclusions, etc. in the aluminum liquid, greatly improve product quality. So, it is an economical material for filtering aluminum alloys.

Filter Mesh Position:

The filter mesh can be cut into any specification, placed on the sprue parting surface of the box pressing, such as the combination of filter net and slag bag, its effect will be better.

1. Use area of filter net: F1 = F2 / AxB

● F1: the cross-sectional area of the casting system.

● F2: the original cross-sectional area of the casting system.

● A: the porosity of the filter screen, generally 50-60%.

● B: the filtration rate of filter screen, generally 60-80%.

Therefore, the cross-sectional area of the casting system is generally 2-4 times that of the casting system without the casting net.

2. Position of filter screen:

A. Place the filter under the sprue cup;

B. Placed on the parting surface under the sprue;

C. Three different positions on the lap surface of the runner.

3. Precautions for use of filter screen:

When the filter is used, it is necessary to guard against oblique pulling, wear and break. The size of the filter block should be greater than the size of the gate area 20-30mm. Handling, handling should be careful to handle, prevent extrusion, moisture.

The mechanism of filtering metal liquid by Fiberglass filter mesh:

The efficiency of our Smokeless Odorless Fiberglass Casting Filter Mesh is driven by a multi-stage filtering process. Initially, the rectifier mechanism slows the flow of metal liquid to reduce eddy currents. This is followed by mechanical filtration to capture larger inclusions, then double filtration forms as the mesh accumulates impurities, and finally, adsorption increases the contact area for chemical reactions, ensuring a clean, high-quality casting.

● Rectifier mechanism: The filter is placed in the pouring process, the metal liquid is increased the resistance during pouring, changes the flow state, and makes the metal liquid slowly flow into the cast cavity, which is not easy to bring eddy current, the filling is stable, the secondary oxidation and slag inclusion are reduced, which is conducive to the floating of inclusions and the slag blocking function of the pouring system.

● Mechanical filtration: There are a large number of inclusions in liquid metal, slag and other large impurities, through the selection of suitable aperture filter to filter out inclusions larger than the aperture size by mechanical methods.

● Double filtration: During the mechanical filtration, the filter net captures many inclusions larger than the aperture and with the increase of the number of inclusions, the double filtration is formed at the entrance of the filter screen. The double filtration make the liquid metal flow fine and have the function of filtering. The liquid metal can be filtered twice.

● Adsorption: The filter mesh has a large specific surface area, the liquid metal flow through the filter is divided into a small liquid flow unit, then the contact area of the liquid metal and the filter medium is increased. The chemical reaction between harmful elements and oxides in the metal melt and the filter surface is adsorbed on the filter mesh surface.

CangChen's Smokeless Odorless Fiberglass Casting Filter Mesh represents the pinnacle of filtration technology for aluminum casting. Engineered for optimal performance, it ensures superior quality, reduced casting costs, and enhanced process stability. For manufacturers seeking a dependable Fiberglass Filter for Aluminum, our Smokeless Odorless Fiberglass Casting Filter Mesh is the ideal choice—delivering excellence from the first pour to the final casting. Smokeless Odorless Fiberglass Casting Filter Mesh.

Application:

Industrial Furnaces: High temp fiberglass mesh filters are used in industrial furnaces to remove particulate matter from exhaust gases before they are released into the atmosphere.

Power Generation: These filters are used in power plants to remove fly ash and other particulate matter from exhaust gases generated by the combustion of fossil fuels.Such as:Filtration of Molten Aluminium.

Steel Production: High temp fiberglass mesh filters are used in steel production to remove impurities from molten steel before it is cast into various shapes.

Chemical Processing: These filters are used in chemical processing plants to remove impurities from various chemical solutions before they are used in various industrial processes.

Aerospace Industry: High temp fiberglass mesh filters are used in the aerospace industry to filter out impurities from hydraulic fluids and lubricants used in aircraft engines and other components.

Automotive Industry: These filters are used in the automotive industry to filter out impurities from lubricants and hydraulic fluids used in various components of vehicles.

Look forward to hearing from you:

Contact Us

+86 158 3011 4065

Guoruiyuan Building, ShengLi North Street, Chang'An District, Shijiazhuang City, Hebei Province, China.

Navigation

Navigation