Molten Aluminium Shunt Combo Bag is woven by fiberglass fabric, also named fiberglass thermal formed combo bag, simply, TF COMBO BAG.

Its main funtion is to filter and evenly distribute molten aluminum in molds.

Three Main Features:

1. New environmental protection material, does not burn during whole use process , no harm to human body.

2. Advanced production equipment, warp and weft standard for base cloth, high temperature resistant coating mesh uniform, the finished product is exquisitely made without burrs.

3. Both sides of the bag adopt square hole fixing device technology, more convenient operation and improve the working rate.

Parameter

Molten Aluminium Shunt Combo Bag provided by CangChen is a state-of-the-art solution designed to filter and evenly distribute molten aluminum in casting molds. From the very first moment, the Molten Aluminium Shunt Combo Bag demonstrates its superiority by combining advanced fiberglass weaving techniques with high-temperature resin coating. This innovative product, also known as a TF COMBO BAG, is the preferred choice for filtering molten metal in industrial settings.

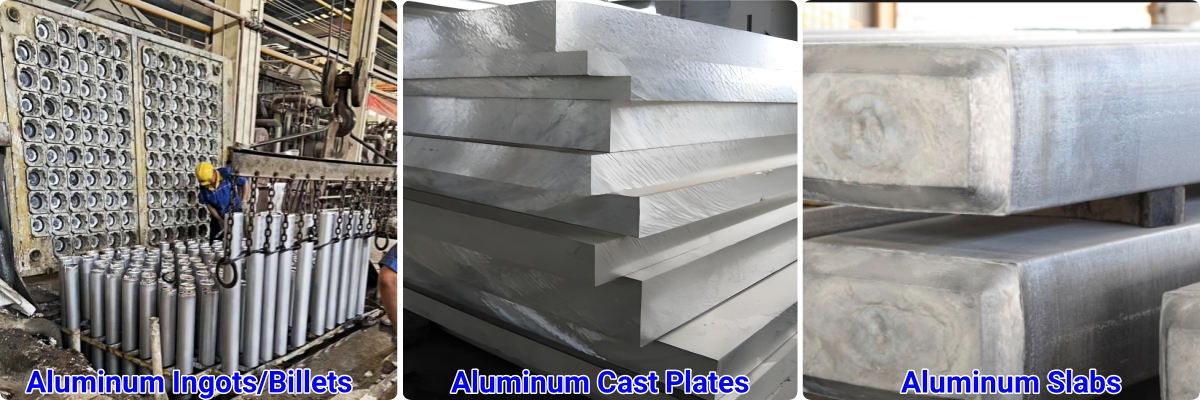

The Molten Aluminium Shunt Combo Bag is expertly woven from high-twist, high-strength alkali-free fiberglass yarn and then coated with a specialized resin. Carbonized at high temperatures, it is capable of withstanding temperatures up to 1000°C. This robust construction makes it ideal for filtering large diameter aluminum ingots, billets, rectangular aluminum slabs, and various aluminum-alloy casting parts. As a key filtration tool, it ensures that the molten aluminum is free from oxides, non-metallic inclusions, and other contaminants, thereby enhancing the quality of the cast products.

Apply to filter large diameter aluminum ingot and billet, rectangular aluminium slab, and aluminum-alloy casting parts.

Fixing Models & Sewing Bags

More details:

Technical Data Sheet:

| Type | Fiberglass Filtration & Shunt Combo Bag For Aluminum |

| Work Temperature | ≤1000℃ |

| Melting Point | 1100℃ |

| Color | White, Brown and Yellow |

| Normal Dimensions | 13" X 5" X 6", 18" X 5" X 6", 18" X 10" X 6" |

| Mesh Openning | 5mesh, 7mesh, 8mesh, 9mesh, 10mesh, 12mesh, 14mesh, 16mesh, 18mesh, 20mesh, 25mesh, and special specifications can be customized. |

| Application | Filtration & Shunt For All Aluminium and aluminium alloy products. |

| Work Time: | 4hours when flow ≤10 kg/min. |

| 1.5hours when flow ≤120 kg/min. | |

| Tensile Strength | 8KGS |

| Filter fineness | 5-50(μm) |

| Filter area | 100(m2) |

| OEM | Logo, Size and Shape of fiberglass filter bag, according to customer's requirement, and also drawing or samples. |

| Certificate | MSDS |

| ISO9001:2015 |

High-Quality Construction: The Molten Aluminium Shunt Combo Bag is manufactured using new environmental protection materials that do not burn during use, ensuring safety and reliability.

Enhanced Durability: Coated with Teflon and reinforced with advanced production equipment, the bag exhibits excellent resistance to wear, corrosion, and high temperatures, ensuring a long service life.

Unique Conical Structure: Designed with conical idlers, the bag provides an optimized filtration pathway that evenly distributes molten aluminum. This design reduces turbulence and improves temperature distribution throughout the mold.

Automatic Functions: Equipped with automatic pressure regulation, thickness detection, and automatic tracking of plate position, the Molten Aluminium Shunt Combo Bag maintains stable grinding pressure and ensures uniform filtration.

Quick Brush Changing: With a rapid brush change design, the system reduces labor intensity and maximizes efficiency by allowing brush replacement in just 3-5 minutes.

Improved Casting Quality: By filtering out oxides, bubbles, and debris, this bag helps improve the yield and quality of aluminum castings. The result is enhanced hardness, uniform surface finish, and superior bending strength in the final products.

Energy and Cost Savings: The efficient design minimizes waste and reduces production costs. Additionally, since the bag does not affect the chemical composition of the aluminum alloy, the molten metal can be directly remelted, contributing to overall cost efficiency.

The Molten Aluminium Shunt Combo Bag is widely used in sand casting, permanent mold, shell mold, draw mold, and investment casting. Its primary role is to filter and evenly distribute molten aluminum, thereby removing harmful impurities like bubbles, ash oxides, and non-metallic inclusions. This process not only enhances the yield but also ensures that the mechanical properties of the aluminum castings meet or exceed international standards.

Metal Casting: Essential for filtering large ingots and billets, ensuring high-quality cast products with improved surface hardness and bending strength.

Manufacturing Plants: Used in industrial settings to remove contaminants from molten metal, thus protecting expensive equipment and ensuring optimal production efficiency.

Recycling and Remelting Operations: The bag's ability to filter impurities without altering the metal composition makes it ideal for operations where aluminum is continuously recycled and remelted.

Custom Casting Projects: Suitable for bespoke casting applications, where custom dimensions or special design requirements are necessary to achieve a unique finish or functionality.

● Helps to reduce the turbulence of metal flow and improve the temperature distribution throughout the mold volume.

● Filter the molten metal and decrease in non-metallic inclusions and oxide films in the liquid metal.

● Ensure the removal of oxides or other debris suspended in the volume.

● Remove the harmful impurities such as bubbles, ash oxides, and various inclusions in aluminum molten liquid.

● Greatly improve the yield of aluminum castings, improve the quality of aluminum products.

● Avoid the problem of other metal components into aluminum solution.

● Does not affect the composition of aluminum alloy.

● Improve the hardness of aluminum casting product with more average surface hard and bending strength.

● Ensure the quality of aluminum castings.

The Benefit of Usage of Fiberglass Filtration Shunt Combo Bag:

● The bag can withstand the liquid temperature of 700℃, it can be used continuously for 4 hours when the flow is not more than 10 kg/min, for 1.5 hours continuously when not more than 120 kg/min.

● It can ensure the removal of oxides or other debris suspended in the volume, remove the harmful impurities such as bubbles, ash oxides, and various inclusions in aluminum molten liquid, greatly improve the yield of aluminum castings, improve the quality of aluminum products, and avoid the problem of other metal components into aluminum solution, does not affect the composition of aluminum alloy, to ensure the quality of aluminum castings.

● It can also improve the mechanical properties of aluminum castings, can increase the hardness of the castings, and the surface hardness is uniform and improve the bending strength of the castings. In this way, the manufacturer can produce terminal products with assured quality.

● At the same time, the shunt bag does not pollute the liquid aluminum, does not affect the chemical properties of the metal, and the aluminium liquid can be directly remelt, thus the cost can be reduced greatly.

● It is the ideal filtration material in the process of aluminum metal smelting.

Bags Compared before and after use:

We can customize the shunt combo/channel bags for you only according to your drawings or samples, if interested, please contact us or leave a message, we will offer you quotation as soon as we receive it.

Application:

To filter and evenly distribute molten aluminum in molds.

To filter large diameter aluminum ingot and billet, rectangular aluminium slab, and aluminum-alloy casting parts.

Used in sand casting, permanent mold, shell mold, draw mold and investment casting, which can remove impurities, reduce turbulence, eliminate air bubbles, thereby improve casting quality and reduce production costs.

High Silica Fiberglass Fabric Filter Mesh For Steel Iron And Copper (Thick Type)

High Silica Fiberglass Fabric Filter Mesh For Steel Iron And Copper (Thick Type)

Fiberglass Cap Filter For Aluminium Pistons Filtration

Smokeless Odorless Fiberglass Casting Filter Mesh For Aluminum

Smokeless Odorless and Flameless Fiberglass Casting Filter Mesh For Aluminum liquid Filtration.

TF Combo Bag For Aluminum Ingot And Slab Filtration

Look forward to hearing from you:

Contact Us

+86 158 3011 4065

Guoruiyuan Building, ShengLi North Street, Chang'An District, Shijiazhuang City, Hebei Province, China.

Navigation

Navigation