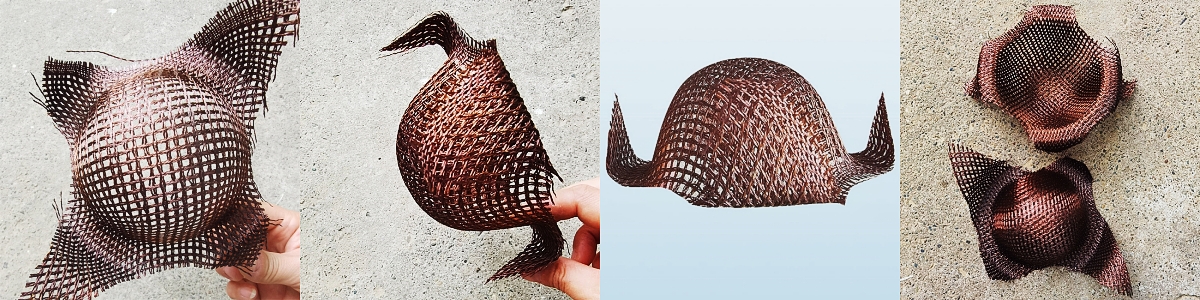

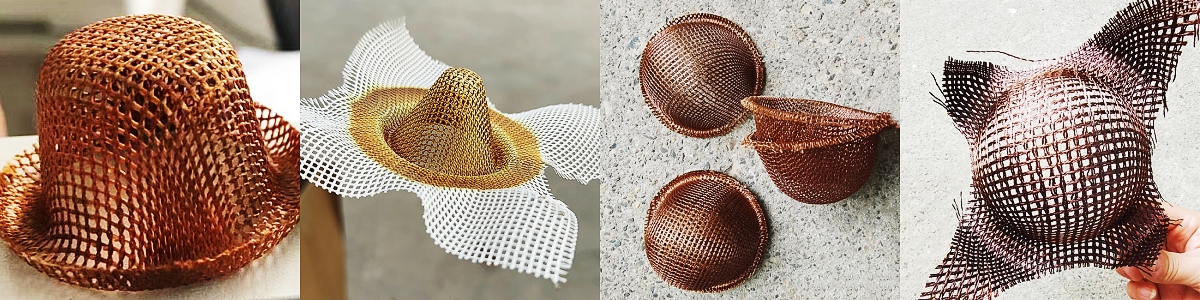

The cap-style high silica fiberglass casting filter mesh is weaved by high silica fiberglass yarn and coated with special refractory coating.

High Silica Fiberglass Cap Filter For Steel Iron And Copper, also can be used on the filtering chemical corrosion liquid and High-temperature gas.

With features of lower cost, convenience to use, no impact on the element of metal casting, good efficacy on filter residue, heat resistance, flame resistance, this casting filter mesh is an ideal material for various liquid metals.

Parameter

High Silica cap-style fiberglass mesh filter is woven by high silica fiberglass yarn and coated with special refractory coating. The maximum temperature resistance can reach up to 1620℃.

It is widely used in is ideal for in-mold filtration of gray, malleable, white, compacted graphite and ductile cast irons, as well as non-ferrous aluminum and copper-based metal alloys and many types of small scale steel casting filtration.

The cap-style high silica fiberglass casting filter mesh is produced by heat resistance fiber in specific techniques and after-treatment. With features of lower cost, convenience to use, no impact on the element of metal casting, good efficacy on filter residue, heat resistance, flame resistance, this casting filter mesh is an ideal material for various liquid metals. High silica fiberglass also can be used on the filtering chemical corrosion liquid and High-temperature gas.

Application:

● Silica mesh filter is ideal for in-mold filtration of gray, malleable, white, compacted graphite and ductile cast irons, as well as non-ferrous aluminum and copper-based metal alloys and many types of small scale steel casting filtration.

● Besides the function of molten metal filters, it could be also used for riser knock-off or de-gating knock-off. Investment casters have also placed the perform cup shape filters in the wax mold gating system to filter metal at pattern entry.

Cap Filter Mesh Features and Functions:

● Carbonized by High Temperature.

● Coated with special resin.

● Smokeless & Odorless & Flameless.

● With one or two staple or not, up to clients' need.

● Effectively remove impurities, reduce turbulence and eliminate air bubbles from molten aluminium.

● Improving the quality of castings and reducing costs.

● It is environment-friendly products.

● All shapes can be customized according to clients' requirements.

| Type | High Silica Fiberglass Filter Mesh For Steel Iron And Copper | |

| Work Temperature | ≤1620℃ | |

| Softening Temperature | 1700℃ | |

| Continuous Working Hours | <10 Min.(1400-1450℃) | |

| <4 Min.(1450-1560℃) | ||

| <15 Seconds.(1560-1620℃) | ||

| Gas Emit | ≤60cm 3/g | |

| Thickness | 1.5mm | |

| Weight | 520-580 g/m2 | |

| Weave Pattern | Mock Leno | |

| Hole Size | 1.5*1.5/2.0*2.0/2.5*2.5mm | |

| Mesh Opening Chosen | White Iron | 1.5mm |

| Gray Iron(Pour weight≤100kgs ) | 1.5mm | |

| Gray Iron(Pour weight≥100kgs ) | 2.0mm | |

| Malleable Iron | 1.5mm | |

| Compacted Graphite Iron | 1.5mm & 2.0mm | |

| Ductile Iron(Pour weight ≤ 100kg) | 2.0mm | |

| Ductile Iron(Pour weight ≥ 100kg) | 2.5mm | |

| Carbon Steel | 1.5mm | |

| Stainless Steel | 1.5mm | |

| Brass | 1.5mm & 2.0mm | |

| Bronze | 1.5mm & 2.0mm | |

| Certificate | MSDS | |

| ISO9001:2015 | ||

Why are Cap Filters so widely used?

First of all, it is imperative to reduce the waste of resources in the metal industry. It can effectively reduce more than half of the slag, impurities caused by the waste phenomenon. This is also the main reason for the wide use of filters, also the main trend.

Secondly, it can effectively remove non-metallic inclusions in liquid metal, which is also a big use of cap filter. It can significantly improve the casting structure and mechanical properties, so that the casting quality is higher, better quality, reduce the rejection rate, reduce tool wear.

Thirdly, Cap Casting filter is not only used to reduce casting porosity, but also can effectively reduce casting surface defects and increase process yield. It can effectively screen and adsorb small pre-slag, so that the quality of metal castings is better, the performance is better, to create high-quality castings.

Application:

Welding and Foundry Operations: In industries such as welding and foundry operations, where high temperatures and flying sparks are common, high silica fiberglass filtration mesh caps are utilized to protect workers' heads and hair. The caps' heat-resistant properties prevent burns and injuries caused by contact with hot sparks or molten metal. The filtration mesh component helps prevent particles, dust, and debris from entering the cap, ensuring a clean and safe working environment.

Chemical and Petrochemical Industries: High silica fiberglass filtration mesh caps find applications in chemical and petrochemical industries, where workers are exposed to corrosive chemicals and potential splashes. These caps offer protection against chemical spills and splashes while allowing air circulation through the filtration mesh, enhancing comfort for the wearer.

High-Temperature Environments: Industries like metallurgy, glass manufacturing, and furnace operations involve working in extreme heat conditions. High silica fiberglass filtration mesh caps provide insulation and protection against radiant heat, helping workers remain comfortable and safe in these environments.

Firefighting and Emergency Response: In firefighting and emergency response scenarios, high silica fiberglass filtration mesh caps can be used as additional protective gear. They offer heat resistance and filtration capabilities, guarding against sparks, embers, and airborne particles present during firefighting operations.

Automotive and Aerospace Manufacturing: In manufacturing processes involving high temperatures and metalworking, such as automotive and aerospace industries, these caps shield workers' heads from potential hazards like hot metal fragments and sparks. The filtration mesh prevents debris from entering the cap and ensures worker safety.

High Silica Fiberglass Fabric Filter Mesh For Steel Iron And Copper (Thick Type)

High Silica Fiberglass Fabric Filter Mesh For Steel Iron And Copper (Thick Type)

Fiberglass Cap Filter For Aluminium Pistons Filtration

Smokeless Odorless Fiberglass Casting Filter Mesh For Aluminum

Smokeless Odorless and Flameless Fiberglass Casting Filter Mesh For Aluminum liquid Filtration.

TF Combo Bag For Aluminum Ingot And Slab Filtration

Look forward to hearing from you:

Contact Us

+86 158 3011 4065

Guoruiyuan Building, ShengLi North Street, Chang'An District, Shijiazhuang City, Hebei Province, China.

Navigation

Navigation