High Silica Fiberglass Filter Mesh is weaved by high silica fiberglass yarn and coated with special refractory coating.

Made from specially treated silica yarns, the thick type silica mesh filters are capable of withstanding pouring temperature up to 1620℃.

It can effectively remove slag, refractory particles and non-metallic inclusions from molten metals.

Silica mesh filter are ideal for in-mold filtration of gray, malleable, white, compacted graphite and ductile cast irons, as well as non-ferrous aluminum and copper-based metal alloys and many types of small scale steel casting filtration.

Parameter

Cangchen High Silica Fiberglass Filtration Mesh is a premium solution designed specifically for the filtration needs in steel, iron, and copper casting processes. This high-performance filtration mesh is crafted using high-quality materials to ensure exceptional efficiency and reliability in your foundry operations.

Our High Silica Fiberglass Filtration Mesh is specially engineered to withstand the demanding conditions of steel, iron, and copper casting. It is designed to effectively capture and remove impurities, such as oxides, inclusions, and slag, from the molten metal, resulting in superior casting quality and reduced defects.

| Type | High Silica Fiberglass Filter Mesh For Steel Iron And Copper | |

| Work Temperature | ≤1620℃ | |

| Softening Temperature | 1700℃ | |

| Continuous Working Hours | <10 Min.(1400-1450℃) | |

| <4 Min.(1450-1560℃) | ||

| <15 Seconds.(1560-1620℃) | ||

| Gas Emit | ≤60cm 3/g | |

| Thickness | 1.5mm | |

| Weight | 520-580 g/m2 | |

| Weave Pattern | Mock Leno | |

| Hole Size | 1.5*1.5/2.0*2.0/2.5*2.5mm | |

| Mesh Opening Chosen | White Iron | 1.5mm |

| Gray Iron(Pour weight≤100kgs ) | 1.5mm | |

| Gray Iron(Pour weight≥100kgs ) | 2.0mm | |

| Malleable Iron | 1.5mm | |

| Compacted Graphite Iron | 1.5mm & 2.0mm | |

| Ductile Iron(Pour weight ≤ 100kg) | 2.0mm | |

| Ductile Iron(Pour weight ≥ 100kg) | 2.5mm | |

| Carbon Steel | 1.5mm | |

| Stainless Steel | 1.5mm | |

| Brass | 1.5mm & 2.0mm | |

| Bronze | 1.5mm & 2.0mm | |

| Certificate | MSDS | |

| ISO9001:2015 | ||

If you are interested in the Fiberglass Filter For Steel, welcome to contact us.

1. It can reduce casting impurities by half and the scrap rate.

2. Filter out impurities, reduce the adverse effects of impurities on the structure and properties of casting alloys, and improve the material properties of castings.

3. Improve the machining performance of castings.

4. Improve process yield.

5. Improve the surface quality of the casting, because the impurities are filtered out, the secondary oxidation is reduced, and the surface quality of the casting is improved.

◆High Silica Glass Fiber: Our filtration mesh is constructed using high-quality high silica glass fibers known for their excellent thermal resistance and durability. This enables the mesh to withstand high temperatures and corrosive environments, ensuring reliable and long-lasting filtration performance.

◆Optimal Filtration Efficiency: The High Silica Fiberglass Filtration Mesh features a fine mesh structure that provides precise and efficient filtration. It effectively traps and separates impurities, ensuring cleaner and purer molten metal for high-quality castings.

◆Versatile Applications: Our filtration mesh is suitable for a range of applications in steel, iron, and copper casting processes. It can be used in various foundry operations, including sand casting, investment casting, continuous casting, and more. Its versatility makes it an essential tool for achieving superior casting results across different metal alloys.

◆Customizable Solutions: At Cangchen, we understand the importance of customization to meet specific filtration requirements. We offer customizable options for our High Silica Fiberglass Filtration Mesh, allowing you to select the optimal mesh size, thickness, and dimensions that suit your casting needs.

◆Improved Casting Quality: By utilizing the High Silica Fiberglass Filtration Mesh, you can significantly enhance the quality of your castings. The mesh effectively removes impurities and contaminants, resulting in improved surface finish, reduced porosity, and enhanced mechanical properties of the final metal components.

Choose Cangchen's High Silica Fiberglass Filtration Mesh to elevate the performance and efficiency of your steel, iron, and copper casting processes. Our reliable and high-quality filtration solutions ensure exceptional casting results while meeting the stringent demands of the foundry industry. Contact us today to discuss your specific filtration requirements and experience the benefits of our advanced filtration mesh technology.

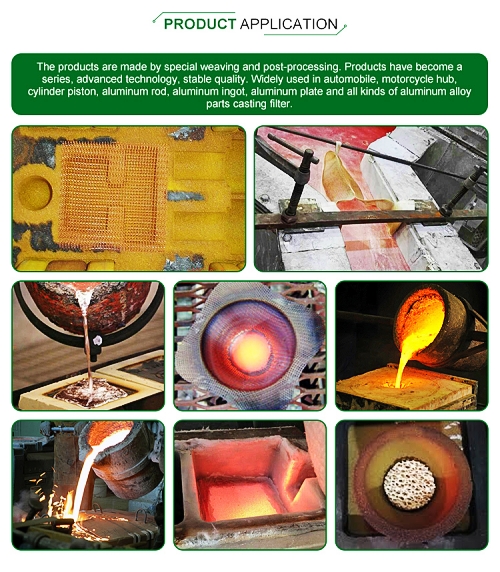

The application of High Silica Fiberglass Filtration Mesh in steel, iron, and copper casting processes offers a wide range of benefits and improvements. This specialized filtration mesh is designed to optimize the quality and integrity of the molten metal, resulting in superior castings. Here are some key applications of the High Silica Fiberglass Filtration Mesh:

◆Impurity Removal: The High Silica Fiberglass Filtration Mesh effectively captures and removes impurities, such as oxides, inclusions, and slag, from the molten metal during steel, iron, and copper casting processes. This leads to cleaner and purer molten metal, minimizing the presence of defects in the final castings.

◆Enhanced Casting Quality: By utilizing the High Silica Fiberglass Filtration Mesh, the overall casting quality is significantly improved. The mesh's fine structure and efficient filtration capabilities ensure the removal of unwanted impurities, resulting in castings with improved surface finish, reduced porosity, and enhanced mechanical properties.

◆Versatile Metal Casting Applications: The High Silica Fiberglass Filtration Mesh is suitable for a wide range of metal casting applications, including steel, iron, and copper. It can be employed in various casting methods such as sand casting, investment casting, continuous casting, and more. Its versatility allows it to cater to different metal alloys and casting processes.

◆High-Temperature Resistance: The High Silica Fiberglass Filtration Mesh is designed to withstand the high temperatures associated with steel, iron, and copper casting. Its high silica glass fibers exhibit exceptional thermal resistance, ensuring reliable filtration performance even in demanding and corrosive environments.

◆Reduced Defects: The effective removal of impurities and contaminants by the High Silica Fiberglass Filtration Mesh helps minimize casting defects such as porosity, inclusions, and surface irregularities. This leads to improved overall casting integrity, reducing the need for rework and enhancing productivity.

◆Customizable Solutions: Cangchen offers customizable options for the High Silica Fiberglass Filtration Mesh, allowing for tailored solutions that meet specific casting requirements. Customizable factors include mesh size, thickness, and dimensions, ensuring optimal filtration performance for each unique application.

● F1: the cross-sectional area of the casting system.

● F2: the original cross-sectional area of the casting system.

● A: the porosity of the filter screen, generally 50-60%.

● B: the filtration rate of filter screen, generally 60-80%.

Therefore, the cross-sectional area of the casting system is generally 2-4 times that of the casting system without the casting net.

● Place the filter under the sprue cup;

● Placed on the parting surface under the sprue;

● Three different positions on the lap surface of the runner.

Our custom High Silica Glass Fiber Filters are designed to excel in high-temperature environments, providing reliable and efficient filtration for various applications. The high silica glass fiber material ensures exceptional thermal resistance, making it ideal for demanding filtration processes in industries such as steel, iron, and copper casting.

With our custom High Silica Fiberglass Filter Mesh, you have the flexibility to select the perfect mesh size, thickness, and dimensions that suit your filtration needs. This customization allows for optimal filtration efficiency and precision, ensuring the removal of impurities, contaminants, and unwanted particles from your molten metal.

Whether you require fine filtration for intricate casting applications or larger mesh sizes for bulk filtering, our custom High Silica Fiberglass Filter Mesh can be tailored to your specific requirements. We work closely with you to understand your filtration goals and deliver a solution that meets your expectations.

The benefits of our custom High Silica Glass Fiber Filters extend beyond enhanced filtration performance. By effectively removing impurities, our filters contribute to improved casting quality, reduced defects, and enhanced mechanical properties of the final metal components. This results in higher productivity, cost savings, and greater customer satisfaction.

Trust in our expertise and dedication to providing customized filtration solutions. Our team of experts is committed to delivering high-quality, custom-designed High Silica Fiberglass Filter Mesh that exceeds your expectations. Experience the difference of personalized filtration solutions by contacting us today. Let us help you optimize your filtration processes and achieve superior results with our custom High Silica Glass Fiber Filters.

Application:

Filtration of Molten Steel

Iron

Copper and Aluminium

Silica Mesh Filter For Foundry Casting Metal Filtration

Silica Mesh Filter For Molten Aluminium, Steel, Iron and Copper Filtration.

Fiberglass Mesh Filter For Molten Metal Casting

High Temperature Carbonized Fiberglass Mesh Filter For Foundry Filtration

Smokeless Odorless Fiberglass Casting Filter Mesh For Aluminum

Smokeless Odorless and Flameless Fiberglass Casting Filter Mesh For Aluminum liquid Filtration.

TF Combo Bag For Aluminum Ingot And Slab Filtration

Look forward to hearing from you:

Contact Us

+86 158 3011 4065

Guoruiyuan Building, ShengLi North Street, Chang'An District, Shijiazhuang City, Hebei Province, China.

Navigation

Navigation