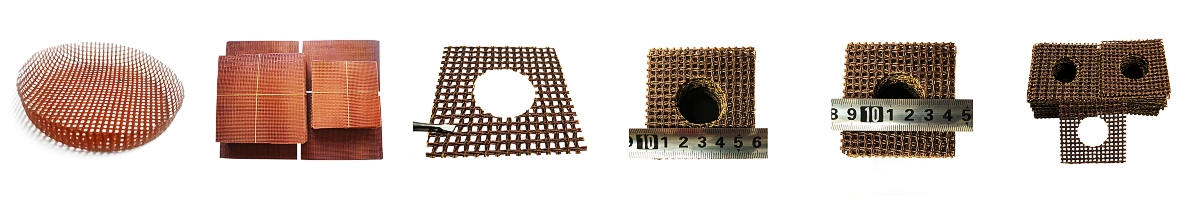

CangChen High Silica Fiberglass Fabric Filter is weaved by high silica fiberglass yarn and coated with special refractory coating, the thick type silica mesh filters are capable of withstanding pouring temperature up to 1620℃.

It can effectively remove slag, refractory particles and non-metallic inclusions from molten metals.

Besides the function of molten metal filters, it could be also used for riser knock-off or de-gating knock-off.

Investment casters have also placed the perform cup shape filters in the wax mold gating systerm to filter metal at pattern entry.

Parameter

Silica mesh filter are ideal for in-mold filtration of gray, malleable, white, compacted graphite and ductile cast irons, as well as non-ferrous aluminum and copper-based metal alloys and many types of small scale steel casting filtration. CangChen Fiberglass Fabric Filter is engineered to deliver outstanding performance in high-temperature and high-chemical environments. Designed for in-mold filtration in steel and iron casting, this filter material plays a crucial role in ensuring high-quality metal production. From the very beginning, our Fiberglass Fabric Filter For Steel And Iron Filtration stands as a reliable and innovative solution for modern industrial applications.

The Fiberglass Fabric Filter For Steel And Iron Filtration is constructed from advanced 96% High Silica Fiberglass filters, providing superior temperature resistance and chemical durability. With a unique woven structure reinforced by high silica content, our filter is capable of withstanding temperatures up to 1620℃, thanks to its High Silica Mesh for 1620℃ temperature resistance filterate. This specialized filter is designed to effectively remove impurities and ensure even distribution of molten metal in casting processes, resulting in enhanced product quality and reduced production defects.

Robust Performance: Our Fiberglass Fabric Filter For Steel And Iron Filtration is engineered with 96% High Silica Fiberglass filters to provide exceptional resistance against extreme heat and corrosive environments. This makes it ideal for use in high-temperature metal casting and other demanding industrial applications.

Extended Lifespan: With its high chemical resistance and durability, the filter remains effective over prolonged use, significantly reducing downtime and maintenance costs.

Efficient Impurity Removal: The filter's design ensures excellent filtration efficiency, effectively removing oxide films, non-metallic inclusions, and other impurities from molten metal.

Uniform Distribution: By evenly distributing molten metal in molds, our Fiberglass Fabric Filter For Steel And Iron Filtration enhances the quality of castings and improves overall production yields.

Diverse Sizes: Our filter is available in a range of sizes to meet the specific requirements of various casting processes, whether for large steel ingots or small-scale precision applications.

Tailored Solutions: We offer customization services to adapt the filter to your unique production needs, ensuring that the final product fits seamlessly into your existing workflows.

Innovative Construction: Composed of high-silica fiberglass with an interwoven design, the filter maintains high intensity and high pass rate, ensuring that impurities are effectively removed from the molten metal.

Enhanced Mechanical Strength: The high tensile strength of our Fiberglass Fabric Filter For Steel And Iron Filtration ensures that it withstands the mechanical stresses of the casting process, providing reliable and consistent performance.

Easy Installation and Replacement: Designed for quick installation and simple maintenance, the filter's modular construction allows for easy replacement without interrupting the production process.

| Type | High Silica Fiberglass Filter Mesh For Steel Iron And Copper | |

| Work Temperature | ≤1620℃ | |

| Softening Temperature | 1700℃ | |

| Continuous Working Hours | <10 Min.(1400-1450℃) | |

| <4 Min.(1450-1560℃) | ||

| <15 Seconds.(1560-1620℃) | ||

| Gas Emit | ≤60cm 3/g | |

| Thickness | 1.5mm | |

| Weight | 520-580 g/m2 | |

| Weave Pattern | Mock Leno | |

| Hole Size | 1.5*1.5/2.0*2.0/2.5*2.5mm | |

| Mesh Opening Chosen | White Iron | 1.5mm |

| Gray Iron(Pour weight≤100kgs ) | 1.5mm | |

| Gray Iron(Pour weight≥100kgs ) | 2.0mm | |

| Malleable Iron | 1.5mm | |

| Compacted Graphite Iron | 1.5mm & 2.0mm | |

| Ductile Iron(Pour weight ≤ 100kg) | 2.0mm | |

| Ductile Iron(Pour weight ≥ 100kg) | 2.5mm | |

| Carbon Steel | 1.5mm | |

| Stainless Steel | 1.5mm | |

| Brass | 1.5mm & 2.0mm | |

| Bronze | 1.5mm & 2.0mm | |

| Certificate | MSDS | |

| ISO9001:2015 | ||

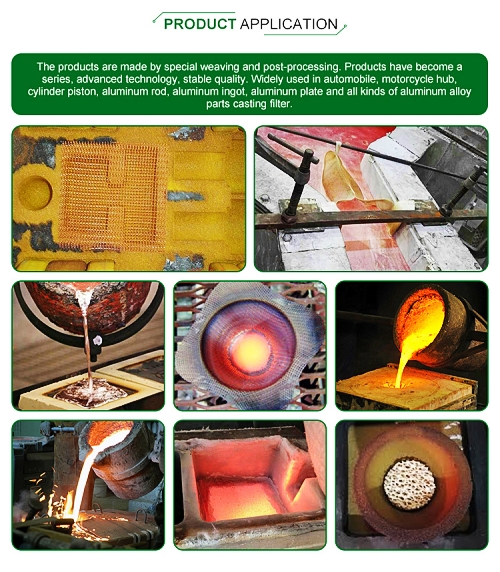

Our Fiberglass Fabric Filter For Steel And Iron Filtration finds extensive application in various industrial processes:

Steel and Iron Casting: It is predominantly used for in-mold filtration during the casting of gray, malleable, white, compacted graphite, and ductile cast irons, ensuring a high-quality finish and uniform composition in the final cast product.

Non-Ferrous Metal Casting: The filter is also effective for filtering molten non-ferrous metals, including aluminum and copper-based alloys, enhancing the purity and quality of castings.

High-Temperature Applications: Thanks to its High Silica Mesh for 1620℃ temperature resistance filterate, the product is suitable for extremely high-temperature environments, making it a critical component in advanced casting and metallurgical processes.

Industrial and Mechanical Applications: Beyond metal casting, the filter is used in other high-performance industrial applications where precise filtration is essential for maintaining product quality and operational efficiency.

Key Points of Usage:

1. Use area of filter net: F1 = F2 / AxB

● F1: the cross-sectional area of the casting system.

● F2: the original cross-sectional area of the casting system.

● A: the porosity of the filter screen, generally 50-60%.

● B: the filtration rate of filter screen, generally 60-80%.

Therefore, the cross-sectional area of the casting system is generally 2-4 times that of the casting system without the casting net.

2. Position of filter screen:

● Place the filter under the sprue cup;

● Placed on the parting surface under the sprue;

● Three different positions on the lap surface of the runner.

The advantages of high silica fiberglass fabric filter mesh comparing with traditional filter materials, including:

Enhanced Casting Quality: By efficiently removing impurities and ensuring uniform metal flow, our filter improves the overall quality and structural integrity of cast metal products.

Cost Savings: Reduced defects and improved yields contribute to lower production costs and increased profitability.

Safety and Reliability: With robust thermal and chemical resistance, the filter ensures safe operation in demanding industrial environments.

Environmental Benefits: High-efficiency filtration leads to reduced waste and better resource utilization, supporting sustainable manufacturing practices.

High Silica Fiberglass Fabric Filter Mesh is a versatile and high-performance industrial filter material that finds its application in various industries. Its unique properties of temperature resistance, chemical resistance, high strength, and high efficiency make it an ideal material for filtration applications that require high precision and performance. As a trusted provider of industrial filtration solutions, CangChen's Fiberglass Fabric Filter For Steel And Iron Filtration is backed by advanced technology, rigorous quality control, and decades of industry expertise. Our commitment to innovation ensures that our products deliver consistent performance, enhance production efficiency, and meet international standards for quality and safety.

Application:

Chemical Industry: The chemical industry is one of the primary users of high silica fiberglass fabric filter mesh. It is used in the filtration of various chemicals, including acids, alkalis, and solvents.

Metallurgical Industry: In the metallurgical industry, high silica fiberglass fabric filter mesh is used in the filtration of molten metal. It helps to remove impurities from the metal and improve its quality.

Petrochemical Industry: In the petrochemical industry, high silica fiberglass fabric filter mesh is used in the filtration of various liquids, including crude oil, diesel, and gasoline.

Pharmaceutical Industry: The pharmaceutical industry uses high silica fiberglass fabric filter mesh in the filtration of various chemicals and drugs. It is also used in the production of medical devices.

Look forward to hearing from you:

Contact Us

+86 158 3011 4065

Guoruiyuan Building, ShengLi North Street, Chang'An District, Shijiazhuang City, Hebei Province, China.

Navigation

Navigation