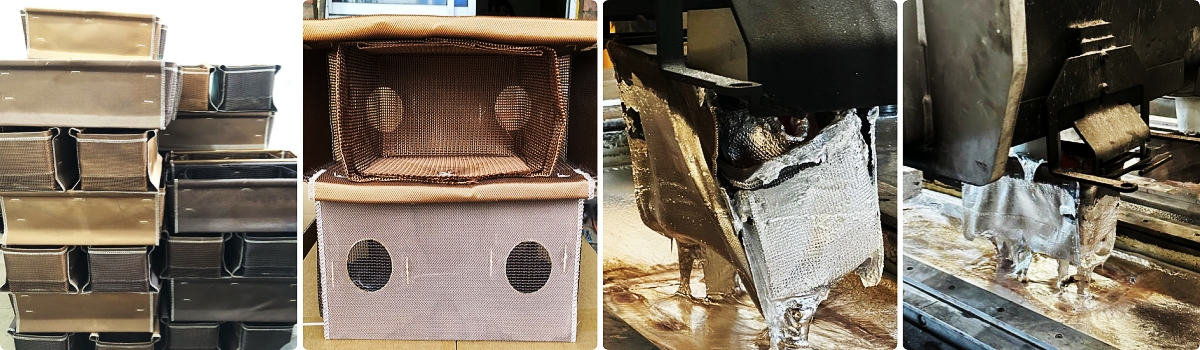

Fiberglass Shunt Combo Bag, also named TF Combo Bag, is weaved by E-fiberglass yarn and treated through special process withstand temperature up to 1000 °C. There are no flame, seldom smoke, no smell during the whole aluminium casting filtration.

Application:

● Apply to filter and evenly distribute molten aluminum in molds.

● Apply to filter large diameter aluminum ingot and billet, rectangular aluminium slab, and aluminum-alloy casting parts.

● Used in sand casting, permanent mold, shell mold, draw mold and investment casting, which can remove impurities, reduce turbulence, eliminate air bubbles, thereby improve casting quality and reduce production costs.

● Improve the temperature distribution of molten metal and control flow of aluminium vertical direct.

● Improve working environment, bags will be producing very little smoke, fumes or flame when molten aluminium flow inside, but it is harmless, no any affect to staff.

Parameter

CangChen TF Combo Filter Bag is a revolutionary filtration solution designed for aluminum ingot filtration and aluminum slab filtration. With its advanced construction and environmental benefits, the TF Combo Filter Bag enhances the efficiency of aluminum casting processes, ensuring superior quality and cost-effectiveness.

The TF Combo Filter Bag is crafted from high-twist, high-strength alkali-free fiberglass yarn, coated with resin, and carbonized at high temperatures. It withstands temperatures up to 1,000 °C, making it ideal for high-temperature precision casting.

Standard size: 6"x5"x13" with a 2.5mmx2.5mm mesh opening, ideal for aluminum ingots, billets, slabs, and casting plates.

Fully customizable dimensions and mesh openings based on specific requirements.

Produces minimal smoke and flames during use, ensuring safety and environmental compliance.

Does not alter the composition of molten aluminum, maintaining the integrity of the metal.

● Usually 6"x 5" x 13" with mesh opening 2.5mmx2.5mm is used for Aluminum Ingots & Billets & slabs & casting plates.

● But all dimensions and mesh opening can be made to your own need, just need your drawings, pictures or samples!

| Type | Fiberglass Filtration & Shunt Combo Bag For Aluminum |

| Work Temperature | ≤1000℃ |

| Melting Point | 1100℃ |

| Color | White, Brown and Yellow |

| Normal Dimensions | 13" X 5" X 6", 18" X 5" X 6", 18" X 10" X 6" |

| Mesh Openning | 5mesh, 7mesh, 8mesh, 9mesh, 10mesh, 12mesh, 14mesh, 16mesh, 18mesh, 20mesh, 25mesh, and special specifications can be customized. |

| Application | Filtration & Shunt For All Aluminium and aluminium alloy products. |

| Work Time: | 4hours when flow ≤10 kg/min. |

| 1.5hours when flow ≤120 kg/min. | |

| Tensile Strength | 8KGS |

| Filter fineness | 5-50(μm) |

| Filter area | 100(m2) |

| OEM | Logo, Size and Shape of fiberglass filter bag, according to customer's requirement, and also drawing or samples. |

| Certificate | MSDS |

| ISO9001:2015 |

Aluminum Ingot Filtration:

Filters impurities during ingot production to ensure superior product quality.

Aluminum Slab Filtration:

Supports molten aluminum filtration for slabs, delivering consistent and reliable outcomes.

Aluminum Filtration Cloth Filter Support:

Functions seamlessly alongside filtration cloth filters to optimize aluminum casting processes.

Easy Integration and Installation:

Replaces existing filter bags seamlessly without system modifications.

Simplifies setup, saving time and labor.

Superior Durability and Strength:

Remains rigid for up to 1.5 hours in molten aluminum.

Handles liquid temperatures of up to 700°C, ensuring reliable performance.

Improved Casting Outcomes:

Enhances mechanical properties of cast products, including uniform surface hardness and bending strength.

Reduces non-metallic inclusions, turbulence, and oxide films, leading to higher-quality aluminum castings.

Cost and Environmental Benefits:

Reduces production costs with minimal material waste and reusability of aluminum liquid.

Contributes to cleaner, greener manufacturing processes.

Place the bag close to the casting cavity for optimal results, minimizing the risk of secondary oxidation.

Position in key locations of the gating system: sprue, runner, inner runner, or sprue cup.

Use appropriate filtration products for the alloy type and pouring temperature, avoiding excessive heat.

Ensure the working area is 4-6 times the blocking section of the pouring system to maintain a steady flow rate.

● Helps to reduce the turbulence of metal flow and improve the temperature distribution throughout the mold volume.

● Filter the molten metal and decrease in non-metallic inclusions and oxide films in the liquid metal.

● Ensure the removal of oxides or other debris suspended in the volume.

● Remove the harmful impurities such as bubbles, ash oxides, and various inclusions in aluminum molten liquid.

● Greatly improve the yield of aluminum castings, improve the quality of aluminum products.

● Avoid the problem of other metal components into aluminum solution.

● Does not affect the composition of aluminum alloy.

● Improve the hardness of aluminum casting product with more average surface hard and bending strength.

● Ensure the quality of aluminum castings.

This bag can also improve the mechanical properties of aluminum castings, can increase the hardness of the castings, and the surface hardness is uniform and improve the bending strength of the castings.

In this way, the manufacturer can produce terminal products with assured quality.

Compared with other kinds of filters, Fiberglass Filtration Shunt Combo Bag has the advantages of low price, convenient use, no change of metal composition, good filter slag and low gas output. Shunt bags can withstand higher temperature and more suitable for high temperature precision casting production.

The TF Combo Filter Bag is the ultimate choice for aluminum ingot filtration, aluminum slab filtration, and other demanding casting applications. With its cutting-edge technology, environmental benefits, and consistent performance, the TF Combo Filter Bag ensures quality, reliability, and efficiency in every casting operation.

Usually out dimensions: 13" x 5"x 6", mesh openning is 2.5x2.5mm, but any dimensions can be customized according to your requirements.

2. Can we get free samples to test?

Of course, we will provide free samples to test, but freight need to be paid by clients.

3. What is the productivity of this bag?

Usually, 10,000pieces per month, if urgent orders, 1-30,0000 pieces also can be produced per month.

4. What is the certification of company and for products?

ISO9001:2015 and MSDS.

Application:

Filter molten aluminum in molds.

Distribute evenly molten aluminum in molds.

Filter large diameter aluminum ingot and billet, rectangular aluminium slab, and aluminum-alloy casting parts.

High Silica Fiberglass Fabric Filter Mesh For Steel Iron And Copper (Thick Type)

High Silica Fiberglass Fabric Filter Mesh For Steel Iron And Copper (Thick Type)

Fiberglass Cap Filter For Aluminium Pistons Filtration

Smokeless Odorless Fiberglass Casting Filter Mesh For Aluminum

Smokeless Odorless and Flameless Fiberglass Casting Filter Mesh For Aluminum liquid Filtration.

Look forward to hearing from you:

Contact Us

+86 158 3011 4065

Guoruiyuan Building, ShengLi North Street, Chang'An District, Shijiazhuang City, Hebei Province, China.

Navigation

Navigation