Fiberglass Filter Mesh Sheets are made of high temperature resistant fiber, woven and processed by special technology.

There are kinds of products series with advanced technology and stable quality.

Application: Car Engine Pistons manufacturing by Aluminum casting process.

Compared with other types of filters, fiberglass casting filter is cheap, easy to use, does not change the metal composition of the casting, has good slag filtering effect and low gas generation.

In addition, it also has high temperature resistance, ablation resistance,good chemical stability, resistance to metal melt erosion and good steel strength.

Parameter

In casting production, steel castings, iron castings, aluminum castings and other alloy castings are prone to quality problems such as slag holes, sand holes and gas holes due to various reasons. Therefore, the removal of non-metallic inclusion in metal melt is of great technical and economic value to improve the yield of castings and the quality of castings.

Filtration of molten aluminum is a critical process in the aluminum casting and manufacturing industry. Molten aluminum, while being processed and transferred, can contain various impurities and non-metallic inclusions that can adversely affect the quality of the final aluminum products. The use of fiberglass mesh filters in this application helps ensure the production of high-quality, clean aluminum products.

Molten aluminum is often subjected to various processes such as melting, refining, alloying, and casting. During these processes, impurities like oxides, slag, dross, and other non-metallic particles can get entrapped in the molten aluminum. If these impurities are not effectively removed, they can lead to defects in the final aluminum products, compromising their mechanical properties and overall quality.

◆ Remove bubbles, oxides, dust and other miscellaneous objects and harmful impurities, eliminate air -eye, slag eye, and improve the yield and appearance quality and inherent quality of the casting.

◆ Improve the mechanical properties of the casting after filtering, such as the stiffness, surface, and bending strength of the casting.

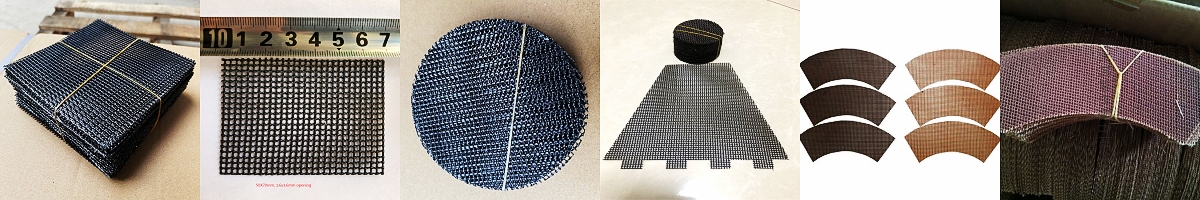

This Fiberglass filter mesh sheets is used by a casting plant for filtering metal melting water, such as aluminum water, iron, and steel. In order to adapt to various applications of castings, we can make alien nets for casting filters. The shape can be like discs, cups, small baskets, etc. We can provide custom sizes according to your requirements.

Fiberglass Mesh Filter is an ideal filter material for various metal melts. It can also be used for the filtration of chemical corrosive liquids and high temperature gases.

| Type | Fiberglass Filter Cloth in roll for aluminum filtration | |

| Yarn type | E-glass fiberglass | |

| Weave type | Leno & plain | |

| Width/roll | 0.9m/1.0m ± 1cm and customized | |

| Length/roll | 100m/150m/200m and customized | |

| Thickness | 0.35-0.6mm | |

| Weight | 150-350g/m2 | |

| Mesh opening | 0.8*0.8/1.0*1.0/1.2*1.2/1.5*1.5/2.0*2.0/2.5*2.5mm and customized | |

| Coating | No Coating | White color and soft fabric |

| Coating with special resin | Brown color and hardness fabric | |

| Work Temperature | 700-900℃ | |

| Softening Temperature | 900℃ | |

| Continuous Working Hours | <20Min.(700-800℃) | |

| Gas Emit | ≤30cm 3/g | |

| Loss on ignition | ≤3% | |

| SiO2 | 58%-65% | |

| Certificate | SDS | |

| ISO9001:2015 | ||

Fiberglass filter mesh sheets can be made in various sizes and shapes to fit different filter housings and systems. They can also be designed to meet specific filtration efficiency, temperature resistance, and chemical resistance requirements.

Fiberglass mesh filters are employed at different stages of the aluminum manufacturing process to capture these impurities and ensure a higher level of purity in the molten aluminum.

①Casting Furnace: In the casting furnace, where aluminum is melted, fiberglass mesh filters can be placed at the outlet of the furnace to catch larger impurities like dross and slag. This prevents these impurities from entering the casting mold and creating defects in the final product.

②Transfer Channels: As molten aluminum is transferred from the furnace to the casting molds or other processing units, fiberglass mesh filters can be installed in the transfer channels. These filters capture finer impurities that might have been missed in the furnace filtration. This step helps ensure that the molten aluminum remains clean and free from contaminants during the entire transfer process.

③Casting Molds: Fiberglass mesh filters can also be integrated into the gating system of the casting molds. This placement captures any remaining impurities before the molten aluminum solidifies and takes the shape of the mold. It contributes to producing aluminum products with smooth surfaces and consistent properties.

Cangchen is the recognized leader in the development and production of Fiberglass filter mesh sheets at home and abroad and possesses excellent innovation capabilities in filter manufacturing technology. We not only customize the casting filtration products to those who have their own brand, but also customize the solutions and services to them. Thank you for reading, we hope it will help you better understand fiberglass filters!

Application:

The use of fiberglass mesh filters in the filtration of molten aluminum plays a vital role in maintaining the quality, purity, and integrity of aluminum products.

By effectively capturing impurities and non-metallic inclusions, these filters contribute to the production of high-performance aluminum components used in various industries, including automotive, aerospace, construction, and more.

High Silica Fiberglass Fabric Filter Mesh For Steel Iron And Copper (Thick Type)

High Silica Fiberglass Fabric Filter Mesh For Steel Iron And Copper (Thick Type)

Smokeless Odorless Fiberglass Casting Filter Mesh For Aluminum

Smokeless Odorless and Flameless Fiberglass Casting Filter Mesh For Aluminum liquid Filtration.

TF Combo Bag For Aluminum Ingot And Slab Filtration

Look forward to hearing from you:

Contact Us

+86 158 3011 4065

Guoruiyuan Building, ShengLi North Street, Chang'An District, Shijiazhuang City, Hebei Province, China.

Navigation

Navigation