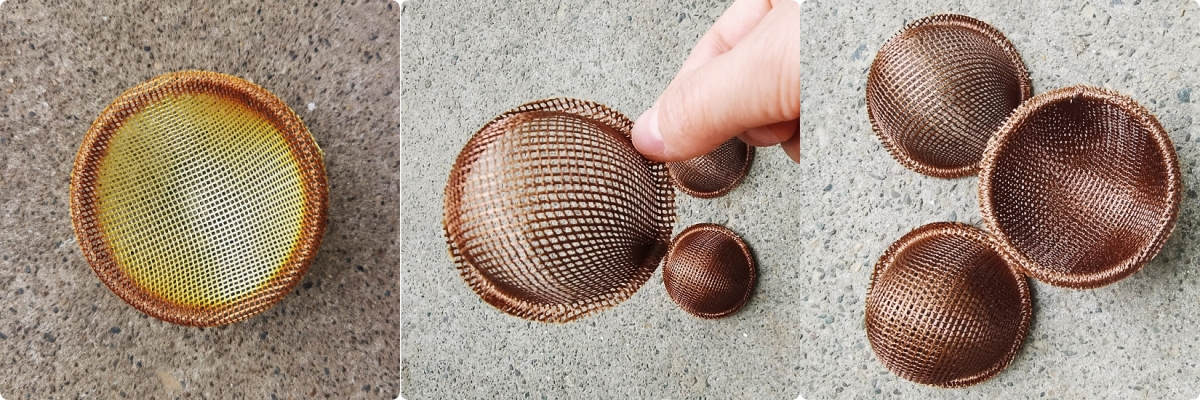

The Cap-Style Fiberglass Filter Mesh

● Weaved with special high-twist & high-strength alkali-free fiberglass yarn

● Coated by special resin

● Special post-treatment under high temperature carbonized

● Smokeless & Odorless & Flameless during whole use process

● With one or two staples or not can be customized

● Individual custom-made products according to client's drawing and samples

Two models:

● Normal yellow(brown) color type (without high temperature carbonization)

● Black color type (with high temperature carbonization)

Widely used in automobile and motorcycle wheels, cylinder pistons, aluminum rods, ingots and plates and precision casting of all types of aluminum alloy casting.

Parameter

Fiberglass cap-style is woven with special high-twist & high-strength alkali-free fiberglass yarn, coated with special resin and produced by carbonizing by special high temperature.

The maximum temperature resistance can reach 900 ℃.

Cap type fiberglass filter mesh is usually a network structure, which is a non-metallic liquid metal purification device with the required mesh opening. Its porosity is higher, the slag collection surface area is larger, and it can reduce the the Reynolds number of the mesh metal surface flowing through the cast filter, then it can make the filler be more stable and reduce the production of secondary oxidation slag in the mold.

Widely used in automobile and motorcycle wheels, cylinder pistons, aluminum rods, aluminum materials, aluminum ingots, aluminum plates and precision casting of all types of aluminum alloy casting.

Why are Cap Filters so widely used?

First of all, it is imperative to reduce the waste of resources in the metal industry. It can effectively reduce more than half of the slag, impurities caused by the waste phenomenon. This is also the main reason for the wide use of filters, also the main trend.

Secondly, it can effectively remove non-metallic inclusions in liquid metal, which is also a big use of cap filter. It can significantly improve the casting structure and mechanical properties, so that the casting quality is higher, better quality, reduce the rejection rate, reduce tool wear.

Thirdly, Cap Casting filter is not only used to reduce casting porosity, but also can effectively reduce casting surface defects and increase process yield. It can effectively screen and adsorb small pre-slag, so that the quality of metal castings is better, the performance is better, to create high-quality castings.

● The usage of cap type fiberglass filter mesh can effectively remove liquid metal and non-metallic inclusions, improve the structure and mechanical properties of castings, improve the high quality standards of precision castings production and reduce the rate of casting defects. It can also reduce tool wear during machining and significantly improve efficiency. In addition, it can reduce porosity in the casting, reduce surface defects and reduce casting and filling lines, significantly increasing the process yield, which is much better than high silicon screen casting filters and cast filter products with straight holes.

● For some castings that require high surface quality and good densification, in order to prevent inclusions and improve the internal quality of the castings, it is very necessary to install a cap type fiberglass filter mesh in the gate system. Especially in the field of small and medium-sized castings such as automobiles, high-speed railways, machine tools and hydraulic parts, the purification effect of the cap filter mesh has been widely recognized by most foundry workers.

Hot press set shape & Side cut trimming

● All shapes can be customized according to clients' requirements

| Type | Fiberglass Cap Filter For Aluminum |

| Models | Normal yellow(brown) color (Without high temperature carbonization) |

| Black color (With high temperature carbonization) | |

| Work Temperature | 700-800℃ |

| Softening Temperature | 900℃ |

| Continuous Working Hours | <20Min.(700-800℃) |

| Gas Emit | ≤30cm 3/g |

| Thickness | 0.5mm |

| Weight | 150-350 g/m2 |

| Hole Size | 0.8*0.8/1.0*1.0/1.2*1.2/1.5*1.5/2.0*2.0/2.5*2.5mm |

| Weave Pattern | Leno |

| Certificate | ISO9001:2015 |

| SDS |

Position of Fiberglass Filter Mesh:

● Place the filter under the sprue cup;

● Placed on the parting surface under the sprue;

● Three different positions on the lap surface of the runner.

Purification mechanism of cap type fiberglass filter mesh:

1. Since the cap fiberglass filter mesh is placed at the bottom of the gate of the sprue cup, runner or sand mold, the molten metal injected from the sprue cup into the cavity can stay momentarily while passing through the position. The slag can be the main small-density inclusions floating and separating from the molten metal. These inclusions also produce deep adsorption when they pass through regular or irregular grids. This phenomenon can continue to purify molten metal before the pouring cup is filled.

2. The role of surface filtration: Surface filtration is a common metal liquid purification function of all casting filters. When the molten metal passes through the casting filter, unfloated or floating inclusions with a relatively large surface area, such as molten slag, are captured by the surface of the casting filter. In addition, the captured inclusions will form a finer filter eye with the cast filter continue trapping subsequent inclusions, thus enhancing the filtration effect. However, at the same time of this surface filtration, with the decrease of the pouring temperature and the increase of the viscosity of the molten metal, as well as the extension of the pouring time, the cap filter mesh will be blocked to varying degrees, thus make filtering effect be worse.

So, the cap filter mesh should be replaced with a new one according to actual casting scenario to keep its best filtering effect.

Functions:

● Effectively remove impurities

● Reduce turbulence and eliminate air bubbles

● Improve the quality of castings and reducing costs

● Does not pollute the aluminum liquid

● Does not affect the chemical properties of the metal

● Aluminum waste containing the filter mesh, aluminum liquid from sprue and the riser can be directly returned to the furnace for remelting

What is use temperature of fiberglass cap filter?

Firstly, It is divided into working temperature and softening temperature.

● The working temperature is 700~800 ° C.

● The softening temperature is 900 ° C.

We need to choose the suitable filter according to the different pouring temperatures of liquid aluminum, rather than let the filter working temperature affect the pouring temperature of the liquid metal in turn, which will cause more casting defects and lose the meaning of filtration.

Secondly, the reasons for the change of fiberglass cap filter temperature:

● The initial temperature of liquid aluminum is too low. This is a more common reason.

● The design of pouring system is unreasonable. The heat dissipation is too fast, or the metal is not preheated, so that the metal liquid is sharply cooled in the process of entering the cavity.

● Operation error. The initial overheating temperature reservation is too high. As far as possible to ensure that the casting process meticulous specification is the main way to solve the problem.

Application:

Filtration of molten aluminium.

Filtration for aluminum rods, ingots and plates.

Filtration for automobile and motorcycle wheels, cylinder pistons.

Filtration for precision casting of all types of aluminum alloy casting.

High Silica Fiberglass Fabric Filter Mesh For Steel Iron And Copper (Thick Type)

High Silica Fiberglass Fabric Filter Mesh For Steel Iron And Copper (Thick Type)

Smokeless Odorless Fiberglass Casting Filter Mesh For Aluminum

Smokeless Odorless and Flameless Fiberglass Casting Filter Mesh For Aluminum liquid Filtration.

TF Combo Bag For Aluminum Ingot And Slab Filtration

Look forward to hearing from you:

Contact Us

+86 158 3011 4065

Guoruiyuan Building, ShengLi North Street, Chang'An District, Shijiazhuang City, Hebei Province, China.

Navigation

Navigation