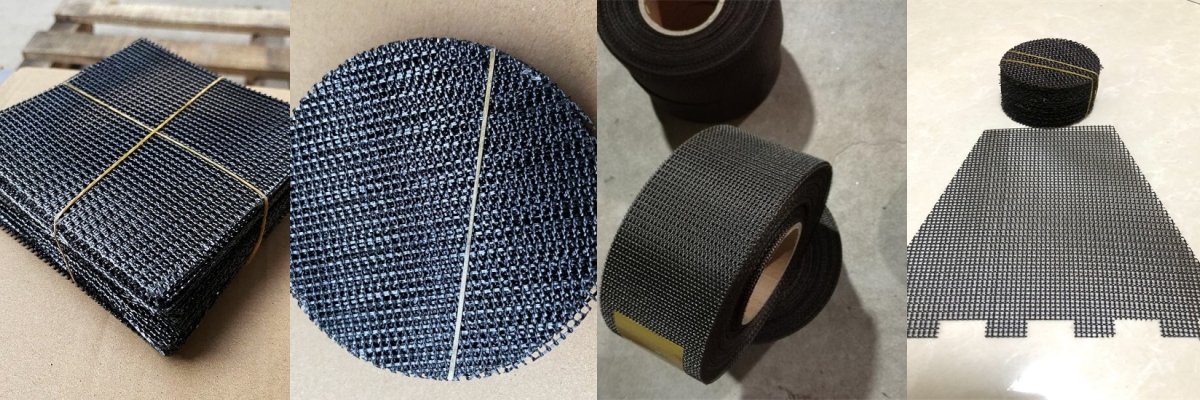

There are kinds of fiberglass filters for molten steel, iron, and aluminum according to the scope of use; according to different shapes, they can be divided into sheet, round, spherical, hat, barrel filters, etc.

According to the different materials used, it can be divided into alkali-free mesh, medium-alkali mesh, high-silica mesh and other filters.

One for cast aluminum is generally made of alkali-free mesh, for cast iron and steel is generally made of high-silica glass fiber mesh.

Parameter

Alkali-free Fiberglass filtration mesh is woven with special high-twist & high-strength alkali-free E-fiberglass yarn, coated with special resin and carbonized by special high temperature. The maximum temperature resistance can reach 900 ℃.

Widely used in automobile and motorcycle wheels, cylinder pistons, aluminum rods, aluminum materials, aluminum ingots, aluminum plates and precision casting of all types of aluminum alloy casting.

| Type | Fiberglass Filter Cloth in roll for aluminum filtration | |

| Yarn type | E-glass fiberglass | |

| Weave type | Leno & plain | |

| Width/roll | 0.9m/1.0m ± 1cm and customized | |

| Length/roll | 100m/150m/200m and customized | |

| Thickness | 0.35-0.6mm | |

| Weight | 150-350g/m2 | |

| Mesh opening | 0.8*0.8/1.0*1.0/1.2*1.2/1.5*1.5/2.0*2.0/2.5*2.5mm and customized | |

| Coating | No Coating | White color and soft fabric |

| Coating with special resin | Brown color and hardness fabric | |

| Work Temperature | 700-900℃ | |

| Softening Temperature | 900℃ | |

| Continuous Working Hours | <20Min.(700-800℃) | |

| Gas Emit | ≤30cm 3/g | |

| Loss on ignition | ≤3% | |

| SiO2 | 58%-65% | |

| Certificate | SDS | |

| ISO9001:2015 | ||

CangChen is proud to introduce our latest product: Alkali-free Fiberglass Filtration Mesh. This innovative filtration mesh is designed to provide exceptional performance in demanding filtration applications.

Made from high-quality alkali-free fiberglass material, our filtration mesh offers excellent thermal and chemical resistance, making it ideal for use in harsh industrial environments. The mesh is woven in a unique pattern that ensures superior filtration efficiency while maintaining a high flow rate.

Our Alkali-free Fiberglass Filtration Mesh is available in a range of sizes and configurations to suit a variety of filtration applications. Whether you need a small mesh filter for laboratory use or a large industrial filter, we have the perfect solution for your needs.

In addition to its superior performance, our Alkali-free Fiberglass Filtration Mesh is also incredibly durable and long-lasting, making it a cost-effective choice for your filtration needs. Plus, with our commitment to quality and customer satisfaction, you can trust that you are getting the best product and service in the industry.

If you are looking for a reliable and efficient filtration solution, look no further than our Alkali-free Fiberglass Filtration Mesh. Contact us today to learn more about this exciting new product and how it can benefit your business.

Features and Functions of Alkali-free Fiberglass Filter Mesh:

● Carbonized by High Temperature

● Coated with special resin

● Smokeless & Odorless & Flameless

● Effectively remove impurities, reduce turbulence and eliminate air bubbles from molten aluminium

● Improving the quality of castings and reducing costs

● The aluminium filtered by this mesh can be recycled again

● It is environment-friendly products

● All shapes can be customized according to clients' requirements

In casting production, the rejection rate of castings is 50 to 60% due to casting problems such as non-metallic inclusions. The inclusions do not only reduce mechanical properties of the casting, but also has a great influence on processability and appearance. For the purification of liquid casting alloys, reducing or filtering various non-metallic inclusions is an important technical measure to obtain good quality castings, and the use of casting filters has become an important auxiliary material for purification of liquid casting alloys.

Alkali-free Fiberglass Filter Mesh Key Points of Usage

1. Use area of filter net: F1 = F2 / AxB

● F1: the cross-sectional area of the casting system.

● F2: the original cross-sectional area of the casting system.

● A: the porosity of the filter screen, generally 50-60%.

● B: the filtration rate of filter screen, generally 60-80%.

Therefore, the cross-sectional area of the casting system is generally 2-4 times that of the casting system without the casting net.

2. Position of filter screen:

● Place the filter under the sprue cup;

● Placed on the parting surface under the sprue;

● Three different positions on the lap surface of the runner.

If you are interested in the Fiberglass Filter For Steel, welcome to contact us.

Application:

Foundry Industry: Alkali-free fiberglass filtration mesh is widely used in the foundry industry to filter out impurities from molten metals. It is used to make filter bags, filter cartridges, and filter discs that are used to filter aluminum, brass, and other metals.

Filtration of molten aluminium.

High Silica Fiberglass Fabric Filter Mesh For Steel Iron And Copper (Thick Type)

High Silica Fiberglass Fabric Filter Mesh For Steel Iron And Copper (Thick Type)

Smokeless Odorless Fiberglass Casting Filter Mesh For Aluminum

Smokeless Odorless and Flameless Fiberglass Casting Filter Mesh For Aluminum liquid Filtration.

TF Combo Bag For Aluminum Ingot And Slab Filtration

Look forward to hearing from you:

Contact Us

+86 158 3011 4065

Guoruiyuan Building, ShengLi North Street, Chang'An District, Shijiazhuang City, Hebei Province, China.

Navigation

Navigation