Zirconia ceramic foam filter is used for molten all types of steel like unalloyed, low alloyed, stainless, and high-alloyed as well as Nickel and Cobalt-based super-alloys.

The best choice for filtering of determined for filtering of steel and steel alloys up to the temperature of 1700℃.

Filters are recommended especially for high quality grades of alloys.

Parameter

Zirconia ceramic foam filter for steel casting can endear the demand of steel technology and get rid of residue and materials which been left behind after the model is been eroded.

With the excellent resistance to attack and corrosion from molten steel liquid, it can effectively remove inclusions, reduce trapped gas from liquid metal and provide laminar flow, and then the filtered metal is significantly cleaner.

Cleaner metal results in higher-quality castings, less scrap, and fewer inclusion defects.

Application:

● For the filtration of molten steel and alloy, large scale iron casting.

● Filters are recommended especially for high quality grades of alloys.

Functions:

● Reduction in inclusion levels

● Good filtration capacity

● Ideal for the filtration of high alloyed steel

● High efficiency

● Filters can be preheated for investment casting application

| Type | Zirconia ceramic foam filter for steel and high alloy |

| Color | Yellow |

| ZrO2(%) | 85-90 |

| Al2O3 (%) | 5-10 |

| SiO2(%) | ≤4 |

| MgO(%) | 4-5 |

| Porosity | 80-90% |

| Bulk Density | 0.8-1.5g/cm3 |

| Compressive strength | ≥1.5Mpa(Room temperature) |

| PPI | 10-40PPI(PPI=pores per inch) |

| Work Temperature | ≤1700℃ |

| Thermal shock resistance (Times/1100°C) | 6 |

| Certificate | ISO9001:2015 |

| REACH & RoHS |

Normal Specifications:

| Dimensions (mm) | Zirconia Ceramic Foam Filter | |

| Pouring Rate(kg) | Filtration Capacity(kg) | |

| 50×50×22 | 3~5 | 30 |

| 50×75×22 | 4~6 | 40 |

| 75×75×22 | 7~12 | 60 |

| 75×100×22 | 8~15 | 80 |

| 100×100×22 | 14~20 | 100 |

| Dia 50×22 | 2~6 | 18 |

| Dia 80×22 | 6~10 | 50 |

| Dia 90×22 | 8~16 | 70 |

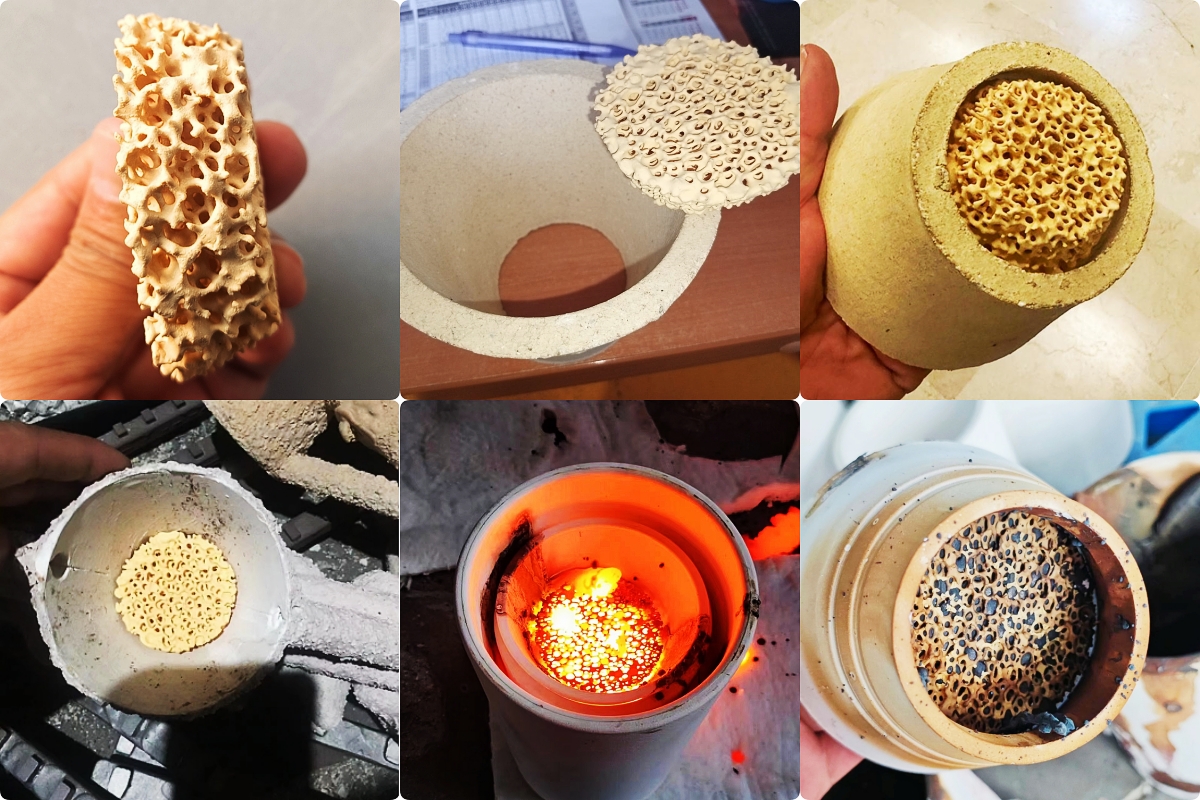

Testing site of our Zirconia ceramic foam filter:

A Corner of our factory:

Quality Inspection:

Three most important key points that make our quality always best are:

● The most advanced testing equipment and technology are adopted today in Hebei Cangchen to ensure the consistant filters quality.

● There is a quality inspection team with rich experience and technology to keep best quality in our quality control department.

● Thanks to many years of product export and feedback information from domestic and foreign customers, we have accumulated considerable experience and expertise in quality control and improvement.

| Dimension deviation of side length or diameter | Thickness dimension deviation |

| <50mm:-1.5~0.5mm | ≤15mm:-1.0~0.5mm |

| ≥50mm:-2.0~0.5mm | >15mm:-2~0.5mm |

| ≥100mm: -2.5~0.5mm | ≥30mm:-3.0mm~0.5mm |

| ≤300mm:-3.5~0.5mm | |

| >300mm:-5mm~1.5mm |

Three most important key points that make our quality always best are:

● The most advanced testing equipment and technology are adopted today in Hebei Cangchen to ensure the consistant filters quality.

● There is a quality inspection team with rich experience and technology to keep best quality in our quality control department.

● Thanks to many years of product export and feedback information from domestic and foreign customers, we have accumulated considerable experience and expertise in quality control and improvement.

For now, Hebei Cangchen is a professional manufacturer with ISO certificate and our Zirconia ceramic foam filters have been passed RoHS And Reach test and certified.

Application:

Filtration of molten steel and alloy

Large scale iron casting

Investment casting

Look forward to hearing from you:

Contact Us

+86 158 3011 4065

Guoruiyuan Building, ShengLi North Street, Chang'An District, Shijiazhuang City, Hebei Province, China.

Navigation

Navigation