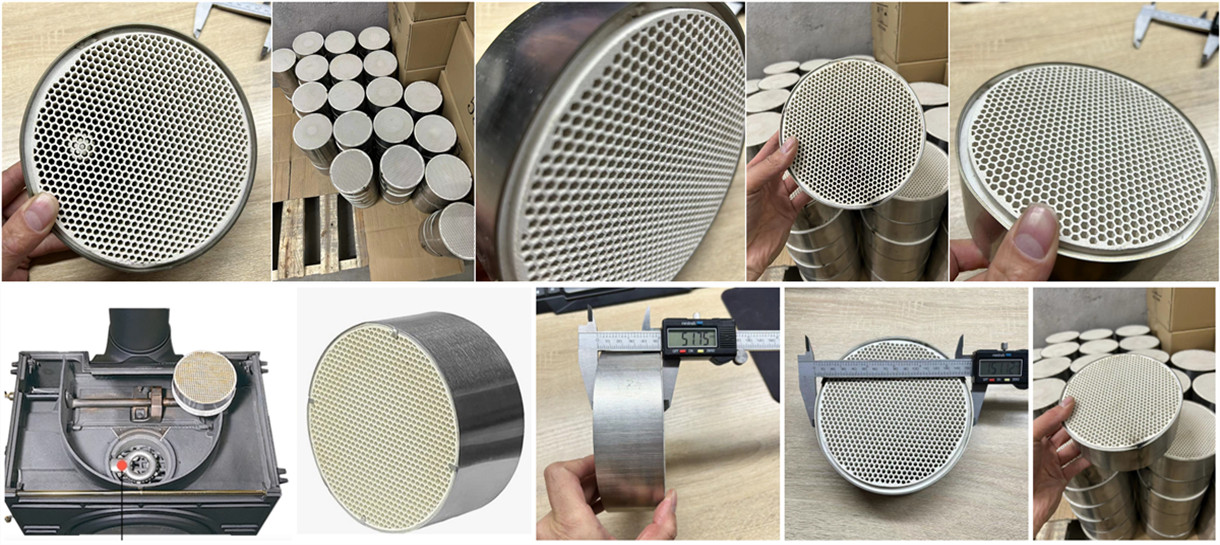

Honeycomb Filter also named Ceramic Honeycomb Filter, Porous Ceramic Filter.

● Produced based Mullite with kinds of hole sizes, which can withstand heavy pouring thermal shock and extreme pouring temperature.

● The cellular design also provides an engineered balance between flow rate and strength and it can effectively capture inclusions and reduce turbulence of the molten metal.

● The extruded ceramic filters have excellent properties of precise dimension, good thermal stability, high specific surface area and resistance to acid and alkali.

● Widely used for ferrous and non-ferrous metal castings, ductile iron, gray cast iron, aluminum casting.

Cangchen as a leading Honeycomb Extruded Porous Ceramic Filter Supplier, we are committed to providing our customers with the best possible products and services. We work closely with our clients to ensure that they get the right filters for their needs and offer excellent after-sales support.

Parameter

Honeycomb extruded ceramic filters are widely used for ferrous and non-ferrous metal castings, ductile iron, gray cast iron, aluminum casting.

Cangchen specializes in the production of Honeycomb Extruded Porous Ceramic Filters that are used in a wide range of industrial applications, including foundries, steelworks, and aluminum casting. These filters are made from high-quality materials and are designed to meet the most stringent quality standards.

Cangchen Honeycomb Extruded Porous Ceramic Filters have a unique structure that makes them ideal for use in high-temperature environments. They offer excellent thermal shock resistance and can withstand extreme temperatures up to 1600°C. These filters are also highly porous, with a uniform pore size distribution that ensures consistent filtration and an excellent flow rate.

And when it comes to finding a reliable Honeycomb Extruded Porous Ceramic Filter Supplier, the best choice is a reputable Honeycomb Extruded Porous Ceramic Filter Company. If you need a high-quality Porous Ceramic Filter for your industrial application, look no further than our Ceramic Honeycomb Filters. Our filters are available in a wide range of sizes and configurations to meet the needs of different applications. We can also customize our filters to meet your specific requirements. As a reliable Honeycomb Extruded Porous Ceramic Filter Supplier, we are committed to providing you with the best possible products and services. Contact us today to learn more about how our Honeycomb Extruded Porous Ceramic Filters can help you achieve your goals.

Introducing the Honeycomb Extruded Porous Ceramic Filter

The perfect solution for industrial applications where high-efficiency filtration is required. Our filter is made from high-quality ceramic materials and is designed to remove impurities and contaminants from liquids and gases.

Our Honeycomb Extruded Porous Ceramic Filter offers numerous benefits for industrial processes. Its unique honeycomb structure provides a large surface area, resulting in exceptional filtration performance. Our filter is capable of removing impurities as small as 1 micron, ensuring the highest level of filtration for your application.

Our filter is extremely durable and can withstand high temperatures, making it perfect for use in harsh industrial environments. The ceramic material is also resistant to chemical corrosion, ensuring long-term use and reliability. The filter is easy to install and maintain, allowing for minimal downtime and increased efficiency.

Our Honeycomb Extruded Porous Ceramic Filter is ideal for use in a variety of applications, including petrochemicals, water treatment, pharmaceuticals, and many others. Its high-efficiency filtration capabilities make it an excellent choice for any industry that requires a reliable and effective filtration solution.

If you're looking for a high-quality Porous Ceramic Filter for your industrial application, look no further than a Ceramic Honeycomb Filter. Choose our Honeycomb Extruded Porous Ceramic Filter for your filtration needs and experience the benefits of our high-quality and durable product. We are committed to providing our customers with the best possible solutions for their filtration requirements, and we stand behind our products with excellent customer service and support. Contact us today to learn more about our Honeycomb Extruded Porous Ceramic Filter and how it can benefit your industry.

Honeycomb Extruded Porous Ceramic Filter Advantages:

● With very high temperature working strength, thermal shock resistance and resistance to metal flow impact ability. In the work without any slag or rupture phenomenon, to ensure the quality of molten metal filtration.

● With very high strength at room temperature and mechanical impact resistance. In use and transport without any rupture or damage, greatly facilitate the use of the filter operation.

● With a very significant filtering effect. It is much higher than the filter effect of fiber filter. Its remarkable filtering effect is related to the filtering mechanism of velocity criterion.

● It can effectively reduce the turbulent flow of metal liquid brought by casting, make the filling smooth and avoid the surface defects of casting.

● It has a large metal flow rate, and the flow rate is stable (different from the foam ceramic filter whose flow rate gradually decreases with the increase of the number of inclusions being captured). Even if the content of inclusions in the molten metal is much, the normal use will not cause the filter clogging.

● With high chemical stability, is not affected by the acid alkaline metal liquid, does not change the chemical composition of metal liquid.

● With very high dimensional accuracy, can be used for automatic placement of the filter on the production line.

Honeycomb Extruded Porous Ceramic Filter Technical Data Sheet

| Material | Corierite | Mullite | Corundum Mullite | Zirconia Mullite | Zirconia Corundum |

| Al2O3 | 35-37 | 50-60 | 65-70 | 68-73 | 68-73 |

| Hole type | Square, Round and Triangle | ||||

| Holes/inch2 | 100CPSI, 200CPSI, 300CPSI | ||||

| Coefficient of thermal expansion(x10-6/℃) | ≤1.8 | ≤4.0 | ≤5.50 | ≤5.50 | ≤5.50 |

| Softening temperature(℃) | 1390 | 1550 | 1600 | 1650 | 1700 |

| Compression Strength(Mpa) | ≥12 | ≥15 | ≥15 | ≥15 | ≥15 |

| Max. Working temperature(℃) | 1350 | 1500 | 1550 | 1580 | 1650 |

| Application | Alluminium alloy casting | Grey cast iron, ductile cast iron and copper alloy casting | Stainless steel casting | ||

| Certificate | ISO9001:2015 | ||||

Honeycomb Extruded Porous Ceramic Filter Specifications

| Class | Dimension(mm) | Hole Size(mm) | Wall Thichness(mm) | Heat Transfer Area(m2/m3) | Prorosity(%) |

| Honeycomb Filter with Square Holes | 40*40*12 | 1.3 | 0.45 | 1580 | 51.3 |

| 40*40*12 | 1.92 | 0.6 | 1190 | 57 | |

| 50*50*12 | 1.3 | 0.45 | 1580 | 51.3 | |

| 50*50*12 | 1.92 | 0.6 | 1190 | 57 | |

| 55*55*12 | 1.3 | 0.45 | 1580 | 51.3 | |

| 55*55*12 | 1.92 | 0.6 | 1190 | 57 | |

| 66*66*12 | 1.3 | 0.45 | 1580 | 51.3 | |

| 66*66*12 | 1.92 | 0.6 | 1190 | 57 | |

| Honeycomb Filter with Round Holes | 40*40*10 | 2.3 | 1.0 | 758 | 436. |

| 40*40*12.5 | 2.3 | 1.0 | 758 | 43.6 | |

| 50*50*12.5 | 2.3 | 1.0 | 758 | 43.6 | |

| 55*55*10 | 2.0 | 1.0 | 1190 | 40 | |

| 66*66*12.5 | 2.3 | 1.0 | 758 | 43.6 | |

| 75*75*15 | 2.3 | 1.0 | 758 | 43.6 | |

| 81*81*12 | 2.3 | 1.0 | 758 | 43.6 | |

| 81*81*15 | 2.3 | 1.0 | 758 | 43.6 | |

| 100*100*20 | 3.5 | 1.0 | 590 | 43.6 | |

| 132*132*20 | 5.0 | 1.2 | 438 | 51 | |

| Honeycomb Filter with Triangle Holes | 40*40*12 | 2 | 0.45 | 1395 | 40 |

| 50*50*12 | 2 | 0.45 | 1186 | 40 | |

| 66*66*12 | 3 | 0.7 | 1186 | 52 | |

| 75*75*12 | 3 | 0.7 | 1186 | 52 | |

| 82*82*13 | 3 | 0.7 | 1186 | 52 | |

| 100*100*15 | 3 | 0.7 | 1186 | 52 |

High-quality Porous Ceramic Filter Display

Functions of Ceramic Honeycomb Filter

● The straight-pore honeycomb ceramic filter has the characteristics of large specific surface area, high strength, and thermal shock resistance. The following effects can be achieved through internal filtration.

● Purify molten metal and remove non-metallic impurities and gases.

● Make the metal liquid filling stable and reduce the whirlpool.

● The honeycomb ceramic filter can simplify the pouring system and improve the process yield.

● Reduce casting pores, optimize and refine metal structure.

● Improve the surface quality and mechanical properties of castings.

● The honeycomb ceramic filter can reduce the scrap rate of castings.

● Reduce machining allowance and increase tool life, reducing casting cost. Get a quote.

Advantages of Honeycomb Filter

● It has very high working strength at high temperatures, thermal shock resistance, and metal flow impact resistance. There is no slag or cracking phenomenon during operation, which ensures the filtering quality of molten metal.

● The honeycomb ceramic filter has a large metal flow rate, and the flow rate is stable. Even in the case of a large number of inclusions in the molten metal, normal use will not cause blockage of the filter.

● With very high dimensional accuracy, it can be used in the production line of automatic filter placement.

● The honeycomb ceramic filter has extremely high normal temperature strength and mechanical shock resistance. There is no rupture or damage during use and transportation, which greatly facilitates the use and operation of the filter.

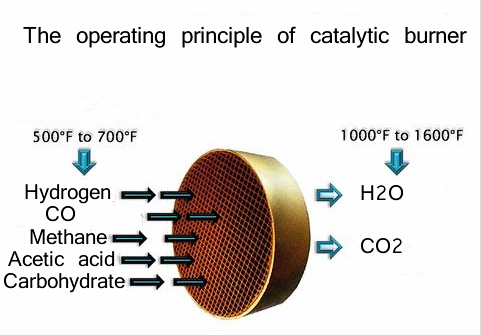

The working principle of Honeycomb Extruded Porous Ceramic Filter

Honeycomb extruded porous ceramic filters are designed to remove impurities from liquids and gases by passing them through a porous ceramic structure. The filter is made up of numerous channels that are separated by thin walls of ceramic material. The channels are typically hexagonal or square in shape, and they are precisely engineered to create a uniform and controlled flow of fluid or gas through the filter. The thin walls of the channels act as a barrier, trapping impurities and allowing only the clean fluid or gas to pass through the filter. The honeycomb structure also allows for a large surface area in a small space, making it an efficient filtration solution.

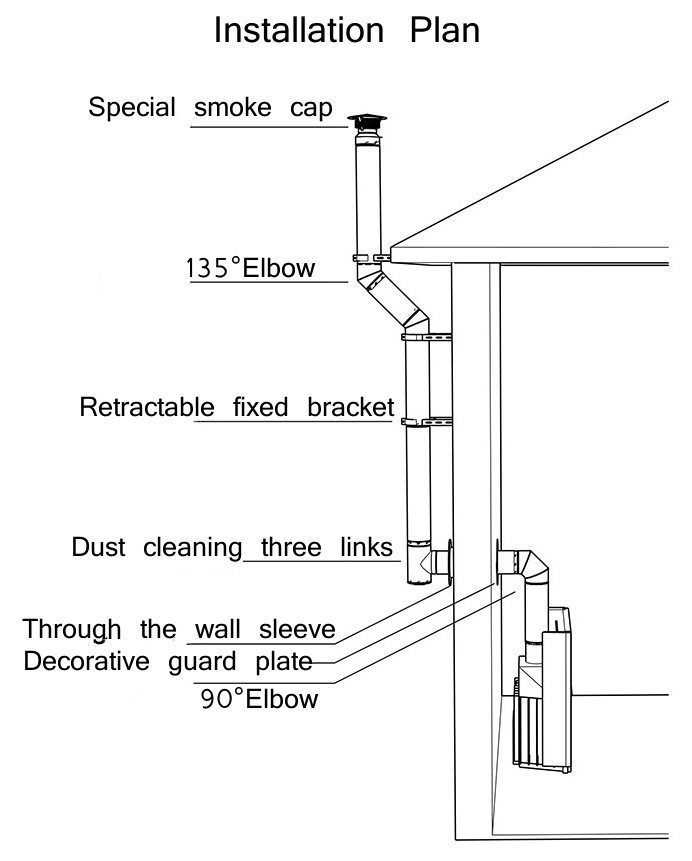

High-quality Porous Ceramic Filter Installation solutions

Application:

Filtration of molten metal: Honeycomb extruded porous ceramic filters are used in the metal casting industry to remove impurities from molten metals. These filters can withstand high temperatures and pressures and can effectively remove impurities, such as slag, sand, and oxides, from the molten metal, resulting in higher-quality metal products.

Air and water purification: Honeycomb extruded porous ceramic filters are used in air and water purification systems. The filters can trap dust, dirt, and other particles, as well as remove impurities, such as heavy metals, from the water or air, making it safer and cleaner to use or breathe.

Chemical and pharmaceutical production: Honeycomb extruded porous ceramic filters are used in chemical and pharmaceutical production to remove impurities and particulates from liquids or gases used in the manufacturing process. These filters can help ensure that the final product meets the required quality standards and does not contain any contaminants that could be harmful to the end user.

Automotive applications: Honeycomb extruded porous ceramic filters are used in automotive applications, such as catalytic converters and diesel particulate filters, to remove harmful pollutants from vehicle emissions. The filters can trap and convert pollutants into less harmful substances, resulting in cleaner emissions and better air quality.

Aerospace applications: Honeycomb extruded porous ceramic filters are used in aerospace applications to remove impurities from fluids and gases used in space missions. The filters can withstand extreme temperatures and pressures and can effectively remove contaminants, ensuring the safety and reliability of the equipment and crew.

Look forward to hearing from you:

Contact Us

+86 158 3011 4065

Guoruiyuan Building, ShengLi North Street, Chang'An District, Shijiazhuang City, Hebei Province, China.

Navigation

Navigation