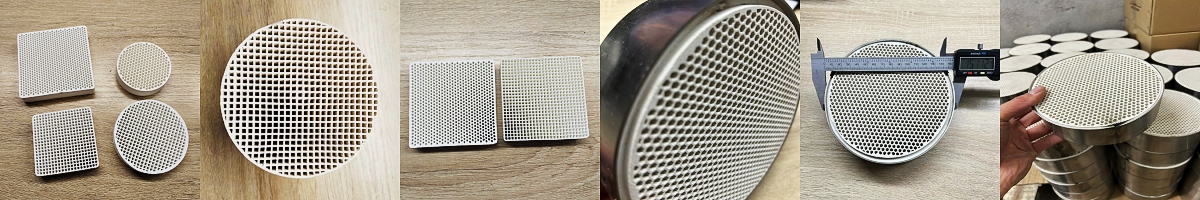

Honeycomb Filter also named Ceramic Honeycomb Filter, Porous Ceramic Filter.

Produced based Mullite with kinds of hole sizes, which can withstand heavy pouring thermal shock and extreme pouring temperature.

The cellular design also provides an engineered balance between flow rate and strength and it can effectively capture inclusions and reduce turbulence of the molten metal.

The extruded ceramic filters have excellent properties of precise dimension, good thermal stability, high specific surface area and resistance to acid and alkali.

Widely used for ferrous and non-ferrous metal castings, ductile iron, gray cast iron, aluminum casting.

Parameter

CangChen Ceramic Honeycomb Filter, the perfect solution for high-temperature filtration needs in various industrial applications. Our Honeycomb Ceramic Filter is an extruded ceramic filter with a unique honeycomb structure that provides excellent filtration efficiency and durability.

The Honeycomb Filter is made of high-quality materials that are designed to withstand extreme temperatures and harsh operating conditions. The honeycomb structure of the filter allows for a high surface area to volume ratio, ensuring efficient filtration of impurities from liquids and gases.

Our Ceramic Honeycomb Filter is available in a range of sizes and configurations to meet the specific requirements of different industrial applications. We offer Honeycomb Filter Quotes that are competitive and customized to meet the needs of our customers.

The Honeycomb extruded ceramic filters are widely used for ferrous and non-ferrous metal castings, ductile iron, gray cast iron, aluminum casting.

With our Ceramic Honeycomb Filter, you can ensure high-quality filtration of your industrial processes, thereby improving the quality of your end products. Our filters are easy to install and maintain, ensuring uninterrupted operation of your industrial processes.

So why wait? Contact us today to get a quote for our Honeycomb Ceramic Filter and experience the benefits of high-quality filtration in your industrial processes.

Ceramic Honeycomb Filter Advantages:

● With very high temperature working strength, thermal shock resistance and resistance to metal flow impact ability. In the work without any slag or rupture phenomenon, to ensure the quality of molten metal filtration.

● With very high strength at room temperature and mechanical impact resistance. In use and transport without any rupture or damage, greatly facilitate the use of the filter operation.

● With a very significant filtering effect. It is much higher than the filter effect of fiber filter. Its remarkable filtering effect is related to the filtering mechanism of velocity criterion.

● It can effectively reduce the turbulent flow of metal liquid brought by casting, make the filling smooth and avoid the surface defects of casting.

● It has a large metal flow rate, and the flow rate is stable (different from the foam ceramic filter whose flow rate gradually decreases with the increase of the number of inclusions being captured). Even if the content of inclusions in the molten metal is much, the normal use will not cause the filter clogging.

● With high chemical stability, is not affected by the acid alkaline metal liquid, does not change the chemical composition of metal liquid.

● With very high dimensional accuracy, can be used for automatic placement of the filter on the production line.

Ceramic Honeycomb Filter Technical Data Sheet

| Material | Corierite | Mullite | Corundum Mullite | Zirconia Mullite | Zirconia Corundum |

| Al2O3 | 35-37 | 50-60 | 65-70 | 68-73 | 68-73 |

| Hole type | Square, Round and Triangle | ||||

| Holes/inch2 | 100CPSI, 200CPSI, 300CPSI | ||||

| Coefficient of thermal expansion(x10-6/℃) | ≤1.8 | ≤4.0 | ≤5.50 | ≤5.50 | ≤5.50 |

| Softening temperature(℃) | 1390 | 1550 | 1600 | 1650 | 1700 |

| Compression Strength(Mpa) | ≥12 | ≥15 | ≥15 | ≥15 | ≥15 |

| Max. Working temperature(℃) | 1350 | 1500 | 1550 | 1580 | 1650 |

| Application | Alluminium alloy casting | Grey cast iron, ductile cast iron and copper alloy casting | Stainless steel casting | ||

| Certificate | ISO9001:2015 | ||||

Ceramic Honeycomb Filter Specifications

| Class | Dimension(mm) | Hole Size(mm) | Wall Thichness(mm) | Heat Transfer Area(m2/m3) | Prorosity(%) |

| Honeycomb Filter with Square Holes | 40*40*12 | 1.3 | 0.45 | 1580 | 51.3 |

| 40*40*12 | 1.92 | 0.6 | 1190 | 57 | |

| 50*50*12 | 1.3 | 0.45 | 1580 | 51.3 | |

| 50*50*12 | 1.92 | 0.6 | 1190 | 57 | |

| 55*55*12 | 1.3 | 0.45 | 1580 | 51.3 | |

| 55*55*12 | 1.92 | 0.6 | 1190 | 57 | |

| 66*66*12 | 1.3 | 0.45 | 1580 | 51.3 | |

| 66*66*12 | 1.92 | 0.6 | 1190 | 57 | |

| Honeycomb Filter with Round Holes | 40*40*10 | 2.3 | 1.0 | 758 | 436. |

| 40*40*12.5 | 2.3 | 1.0 | 758 | 43.6 | |

| 50*50*12.5 | 2.3 | 1.0 | 758 | 43.6 | |

| 55*55*10 | 2.0 | 1.0 | 1190 | 40 | |

| 66*66*12.5 | 2.3 | 1.0 | 758 | 43.6 | |

| 75*75*15 | 2.3 | 1.0 | 758 | 43.6 | |

| 81*81*12 | 2.3 | 1.0 | 758 | 43.6 | |

| 81*81*15 | 2.3 | 1.0 | 758 | 43.6 | |

| 100*100*20 | 3.5 | 1.0 | 590 | 43.6 | |

| 132*132*20 | 5.0 | 1.2 | 438 | 51 | |

| Honeycomb Filter with Triangle Holes | 40*40*12 | 2 | 0.45 | 1395 | 40 |

| 50*50*12 | 2 | 0.45 | 1186 | 40 | |

| 66*66*12 | 3 | 0.7 | 1186 | 52 | |

| 75*75*12 | 3 | 0.7 | 1186 | 52 | |

| 82*82*13 | 3 | 0.7 | 1186 | 52 | |

| 100*100*15 | 3 | 0.7 | 1186 | 52 |

The straight-pore honeycomb ceramic filter has the characteristics of large specific surface area, high strength, and thermal shock resistance. The following effects can be achieved through internal filtration:

Purify molten metal and remove non-metallic impurities and gases;

Make the metal liquid filling stable and reduce the whirlpool;

The honeycomb ceramic filter can simplify the pouring system and improve the process yield;

Reduce casting pores, optimize and refine metal structure;

Improve the surface quality and mechanical properties of castings;

The honeycomb ceramic filter can reduce the scrap rate of castings;

Reduce machining allowance and increase tool life, reducing casting cost. Get a quote.

1.It has very high working strength at high temperatures, thermal shock resistance, and metal flow impact resistance. There is no slag or cracking phenomenon during operation, which ensures the filtering quality of molten metal.

2. The honeycomb ceramic filter has a large metal flow rate, and the flow rate is stable. Even in the case of a large number of inclusions in the molten metal, normal use will not cause blockage of the filter.

3. With very high dimensional accuracy, it can be used in the production line of automatic filter placement.

4. The honeycomb ceramic filter has extremely high normal temperature strength and mechanical shock resistance. There is no rupture or damage during use and transportation, which greatly facilitates the use and operation of the filter.

Application:

Filtration of Stainless steel casting

Filtration of Alluminium alloy casting

Filtration of Grey cast iron, ductile cast iron and copper alloy casting

Look forward to hearing from you:

Contact Us

+86 158 3011 4065

Guoruiyuan Building, ShengLi North Street, Chang'An District, Shijiazhuang City, Hebei Province, China.

Navigation

Navigation