Ceramic Foam Filter Plate is made by the organic foam sponge with three-dimensional network structure and connected pores is used as the carrier, which is infiltrated into the special ceramic slurry with thixotropy, and a special rolling process is adopted to make the ceramic slurry evenly spread on the skeleton of the carrier, and then finished by roasting at high temperature after drying curing.

Suitable for the filtration and purification of aluminum and alloy solutions with high temperature up to 1000 ℃.

Click here to get more information of user manual.

Do you want to know more function for the air purification as a carrier?

Parameter

Alumina Ceramic Foam Filter Plate is produced by organic foam sponge with three-dimensional network structure and connected pores is used as the carrier, which is infiltrated into the special ceramic slurry with thixotropy, and a special rolling process is adopted to make the ceramic slurry evenly spread on the skeleton of the carrier, and then finished by roasting at high temperature after drying curing.

Alumina foam ceramic is a kind of foam material made from high purity alumina. The foam ceramics have the characteristics of uniform porosity, high temperature resistance, heat shock resistance, wear resistance and chemical stability.

Alumina Ceramic Foam Filter Plate is mainly used in the melting filtration of aluminum and aluminum alloys.

It can efficiently filter residues such as oxide slag, oxide scale, non-metallic inclusions and gate groove linings in molten aluminum, and solve the problem of aluminum and aluminum alloys being sensitive to internal defects.

The unique production process and detection method make the alumina filter plate with high opening rate, uniform pore structure and high surface strength.

Available in 7" to 26", mesh up to 60ppi filter plates.

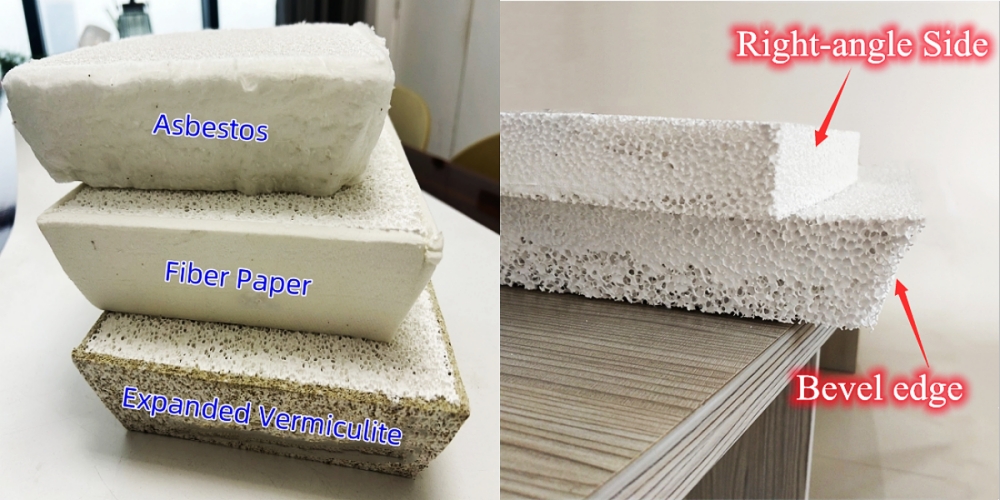

| Edge Covering | Side Cutting |

| Asbestos-Normal | Right-angle Side |

| Fiber Paper-Normal | Bevel Edge |

| Expanded Vermiculite-Superior | Round Edge |

Why is alumina ceramic foam filter plate used in filtration of aluminum liquid?

In order to meet the increasing quality requirements of aluminum castings, the use of alumina ceramic foam filters (plate) is becoming more and more important. Filters are also widely used in ordinary sand casting, such as wet mold casting, and fixed mold casting, such as automotive aluminum parts casting.

Alumina foam ceramic filter plate is very important to the quality of aluminum melt, which affects the subsequent processing performance and the quality of final products to a great extent.

Therefore, all countries in the world attach great importance to the purification of aluminum melt.

Widely used in casting processing, water treatment, chemical industry, environmental protection and other industries. It is the ideal liquid aluminum filter; Catalyst support, and good sound insulation, thermal insulation material. Product shapes, sizes, and voids PPI can be designed and manufactured on request.

● In the smelting process, aluminum is exposed to the furnace atmosphere in a molten or semi-molten state, easy to oxidize, easy to react with water vapor and absorb hydrogen, easy to form various forms of non-metallic slag (such as furnace lining debris, chloride, carbide in flux, etc.) and coarse metal intercompound particles and so on.

● Part of the waste that makes up the charge brings some non-aluminum impurities into circulation.

● Because the waste comes from the factory of each process waste and waste outside the plant, so the way is different, the composition is complex, the quality is poor. These impurities often make the billet produce bubbles and inclusions, which seriously affect the purity of the metal melt, and further affect the machining properties, mechanical properties, corrosion resistance and the appearance quality of the product.

● Alumina foam ceramic filter plate can effectively remove all kinds of inclusions with fineness up to micron level in aluminum liquid, make aluminum liquid into a steady laminar flow, which is conducive to filling.

● It has a unique mullite-corundum structure, good mechanical strength and chemical stability, excellent resistance to aluminum liquid erosion performance.

● It can obtain stable filtration effect by strict control of hole size and through hole rate.

● The ceramic foam filter plate is surrounded by a sealing ceramic fiber liner, which facilitates the seal of the filter plate in the filter box to ensure that there is no metal liquid sideflow.

| Color | White |

| Edge Covering | Asbestos---Normal |

| Expanded Vermiculite---Superior | |

| PPI | 10/20/30/40/50/60(Customized) |

| AL2O3 Content | ≥83% |

| Porosity | ≥85% |

| Proportion | 0.3g/cm³-0.45g/cm³ |

| Refractory temperature | ≥1500℃ |

| Bending strength | >0.5Mpa |

| Thermal shock resistance | 750℃/5times |

| Solubility | Under the temperature of metal aluminum and aluminum alloy solution, the filter equipment will not chemically react with the solution and dissolve. |

| Certificate | ISO9001:2015 |

| REACH & RoHS |

| Dimension(mm) | Tolerance(mm) | Thickness(mm) | Rake Angle | Tortuosity(mm) | Diagonal Line | Effective Filtration Area(%) | Filtration Flow Range(Kg/min.) |

| 12"/(305*305*50) | ±3 | 50±1 | 17.5°+1° | Max.4 | <1% of side length | 82 | 52-158 |

| 15"/(381*381*50) | ±3 | 50±1 | 17.5°+1° | Max.4 | <1% of side length | 86 | 86-255 |

| 17"/(432*432*50) | ±3 | 50±1 | 17.5°+1° | Max.4 | <1% of side length | 87 | 112-345 |

| 20"/(508*508*50) | ±4 | 50±1 | 17.5°+1° | Max.4 | <1% of side length | 89 | 158-480 |

| 23"/(584*584*50) | ±4 | 50±1 | 17.5°+1° | Max.4 | <1% of side length | 91 | 212-645 |

| Item | Allowable variation | |||

| ≤381mm | 381mm~430mm | ≥430mm | ||

| Side length allowable variation(mm) | ±3 | ±4 | ±5 | |

| Diagonal line allowable variation(mm) | ±5 | ±7 | ±9 | |

| Plane clearance allowable variation(mm) | ≤3 | ≤6 | ||

| Thickness allowable variation(mm) | ±2 | |||

| Side rake allowable variation(°) | ±1° | |||

Remarks: ● Diagonal deviation refers to the difference between the lengths of two diagonals on large surface of filter plate. ● The plane gap is to place large surface of filter plate on platform and measure the gap between filter plate and platform. ● Side bevel refers to the angle between side bevel and large surface. ● The filter plates involved in the table are all products with a theoretical thickness of 50mm and side inclination angle 17.5°. | ||||

Three most important key points that make our quality always best are:

● The most advanced testing equipment and technology are adopted today in Hebei Cangchen to ensure the consistant filters quality.

● There is a quality inspection team with rich experience and technology to keep best quality in our quality control department.

● Thanks to many years of product export and feedback information from domestic and foreign customers, we have accumulated considerable experience and expertise in quality control and improvement.

For now, Hebei Cangchen is a professional manufacturer with ISO certificate and our Alumina ceramic foam filters have been passed RoHS And Reach test and certified.

As a professional manufacturer and exporter, Hebei Cangchen has accumulated considerable experience and expertise in quality control and improvement due to many years of product export and feedback information from domestic and foreign customers.

● Transmittance---Light transmittance refers to the effective filtering area of plate. The higher the transmittance, the fewer blind holes, the more effective filter holes (display holes), and the better the filtering effect.

● Porosity---Porosity refers to the percentage of the total volume of pores in the filter plate to the total volume. The porosity determines the filtration capacity per unit volume. The larger the porosity, the greater the filtration flow of the filter plate and the stronger the filtration capacity, and vice versa.

● Pore uniformity---Pore uniformity is used to describe the difference between the actual number of pores per 25.4mm length in the filter plate and the theoretically required number of pores. The smaller the gap, the better the product quality. If the gap is too large, the filter plate will reduce the retention capacity of impurities or the filtration speed of the melt is too slow, which cannot meet the individual requirements of users in production. The size of the pore uniformity mainly depends on the foam used in the production of the filter plate. The pore uniformity of the foam is good, and the pore uniformity of the filter plate is good, so the selection of the foam is extremely important.

● Compressive strength---The higher the compressive strength, the more durable the product, the better the quality, and vice versa.

● Using Method---Please click here to check more information.

Do you have any interesting in special-shapedalumina ceramic foam filters?

Application:

Filtration of molten aluminium and alloy.

To filter large diameter aluminum ingot and billet, rectangular aluminium slab, and aluminum-alloy casting parts.

As a variety of gas-solid, liquid-solid separation media, catalyst carrier, burner and sound absorption & environmental protection fields.

Look forward to hearing from you:

Contact Us

+86 158 3011 4065

Guoruiyuan Building, ShengLi North Street, Chang'An District, Shijiazhuang City, Hebei Province, China.

Navigation

Navigation