Alumina Ceramic Foam Filter is mainly used for the filtration of molten aluminium and alloys in foundries and cast houses. With the excellent resistance to attack and corrosion from molten aluminum, the alumina foam filters can effectively remove inclusions, reduce trapped gas and provide laminar flow, and then the filtered metal is significantly cleaner. Cleaner metal results in higher-quality castings, less scrap, and fewer inclusion defects, all of which contribute to the bottom-line profit.

Cangchen is a recognized leader in the development and production of casting filters both at home and abroad, with excellent innovation capability in filter manufacturing technology. We not only customize foundry filtration products for customers with their own brands but also customize alumina ceramic foam filter solutions and services for them.

Parameter

Alumina Ceramic Foam Filter is a high-performance filter that is designed for use in the metal casting industry. The filter is made from high-quality alumina ceramic material that provides excellent filtration properties and durability.

Alumina ceramic foam filters are mainly used in the purification process production of non-ferrous alloys such as aluminum and aluminum alloys, and can also be used as gas-solid, liquid-solid separation medium, catalyst substrate, ceramic burner, sound absorption, environmental protection, and other fields.

Ceramic foam filter plays a vital role in removing these impurities and preserving high-quality castings.

The Alumina Ceramic Foam Filter offers several key features and benefits that make it an ideal choice for metal casting applications. These include:

1. High Filtration Efficiency:

The filter has a porous structure that ensures high filtration efficiency. It effectively removes impurities, such as slag, dross, and non-metallic inclusions, from molten metal, resulting in higher-quality castings.

2. Improved Metal Quality:

The use of our ceramic foam filter can improve the mechanical properties of castings, such as tensile strength, elongation, and impact strength, as well as the surface finish.

3. High-Temperature Resistance:

The filter is designed to withstand high temperatures, up to 1600°C, without melting or degrading. This makes it ideal for use in demanding casting processes, such as steel casting.

4. Chemical Resistance:

The filter has excellent chemical resistance, which ensures that it can be used with a wide range of metals and alloys without any adverse reactions.

5. Cost-Effective:

Our Alumina Ceramic Foam Filter offers a cost-effective solution for improving the quality of metal castings. It is an affordable option that can save you money in the long run by reducing the need for rework and scrap.

1. Excellent heat shocks

2. High-intensity, no loose ceramic particles or powder

3. Three-dimensional connection mesh structure and high pore rate

4. Large residue surface area, large internal surface area

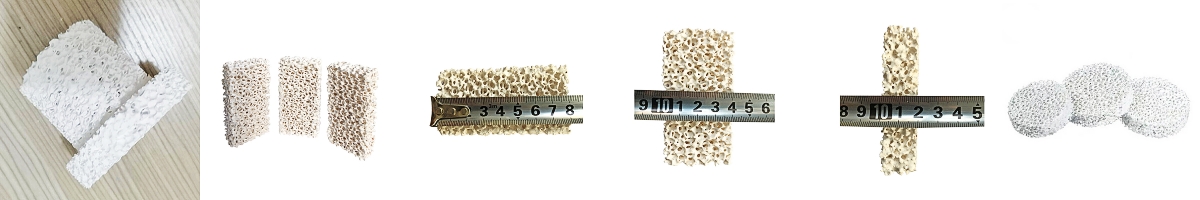

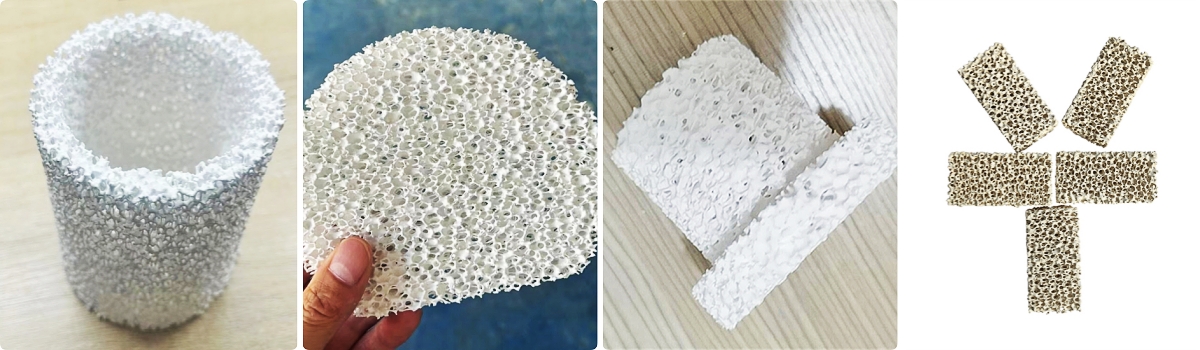

5. Various sizes, shapes and pores are available

6. Granules greater than the aperture are captured on the top of the ceramic foam filter

7. Smaller particles are captured by the filter cake produced by larger particles

8. The finer particles are captured in the hole of the filter

| Type | Alumina ceramic foam filter for aluminum and alloy |

| Main material | Al2O3, SIO2 |

| Work Temperature | ≤1200℃ |

| Color | White |

| PPI | 10/20/30/40PPI(PPI=pores per inch) |

| Porosity | 80-90% |

| Compressive strength | ≥0.8Mpa(Room temperature) |

| Bulk Density | 0.4-0.5g/cm3 |

| Certificate | ISO9001:2015 |

| REACH & RoHS |

1. Purify metal molten liquid

2. Simplify pouring system

3. Improve the casting metallographic structure

4. Reduce inclusions in castings

5. Reduce the reoxidation defects of castings internal

6. Reduce surface defects of castings after machining

7. Improve casting qualification rate

The Alumina Ceramic Foam Filter is suitable for use in a wide range of metal casting applications, including:

Steel casting

Aluminum casting

Copper casting

Iron casting

Zinc casting

Magnesium casting

Three most important key points that make our quality always best are:

● The most advanced testing equipment and technology are adopted today in Hebei Cangchen to ensure the consistant filters quality.

● There is a quality inspection team with rich experience and technology to keep best quality in our quality control department.

● Thanks to many years of product export and feedback information from domestic and foreign customers, we have accumulated considerable experience and expertise in quality control and improvement.

For now, Hebei Cangchen is a professional manufacturer with ISO certificate and our Alumina ceramic foam filters have been passed RoHS And Reach test and certified.

Do you have any interesting in special-shapedalumina ceramic foam filters?

Cangchen Alumina Ceramic Foam Filter is a high-quality product that offers exceptional filtration efficiency, durability, and cost-effectiveness. It is designed to help improve the quality of metal castings and is suitable for use in a wide range of casting applications. If you are looking for a reliable and effective filter for your metal casting processes, our Alumina Ceramic Foam Filter is a perfect choice.All types can be customized according to client's own requirements, if interested, please contact Cangchen Sales Team.

Application:

Filtration of Molten Aluminium

Copper alloy

Black metal, including gray

Delays alloys and steel alloys

Look forward to hearing from you:

Contact Us

+86 158 3011 4065

Guoruiyuan Building, ShengLi North Street, Chang'An District, Shijiazhuang City, Hebei Province, China.

Navigation

Navigation