Alumina ceramic foam filter is a new type of filter with low density, high porosity, and three-dimensional network skeleton structure. It is widely used in the aluminum processing industry to filter molten aluminum, thereby improving the quality of aluminum.

Alumina foam ceramic filter plate is very important to the quality of aluminum melt, which affects the subsequent processing performance and the quality of final products to a great extent. Therefore, all countries in the world attach great importance to the purification of aluminum melt.

Parameter

Alumina Ceramic Foam Filter is produced with the organic foam sponge with three-dimensional network structure and connected pores is used as the carrier, which is infiltrated into the special ceramic slurry with thixotropy, and a special rolling process is adopted to make the ceramic slurry evenly spread on the skeleton of the carrier, and then finished by roasting at high temperature after drying curing.

Mainly for the filtration of molten aluminium and alloys in foundries andcast houses. With the excellent resistance to attack and corrosion from molten aluminum, the filter can effectively remove inclusions, reduce trapped gas and provide laminar flow,and then the filtered metal is significantly cleaner.

There are many reasons for aluminum pollution:

● In the smelting process, aluminum is exposed to the furnace atmosphere in a molten or semi-molten state, easy to oxidize, easy to react with water vapor and absorb hydrogen, easy to form various forms of non-metallic slag (such as furnace lining debris, chloride, carbide in flux, etc.) and coarse metal intercompound particles and so on.

● Part of the waste that makes up the charge brings some non-aluminum impurities into circulation.

● Because the waste comes from the factory of each process waste and waste and waste outside the plant, so the way is different, the composition is complex, the quality is poor. These impurities often make the billet produce bubbles and inclusions, which seriously affect the purity of the metal melt, and further affect the machining properties, mechanical properties, corrosion resistance and the appearance quality of the product.

● Alumina foam ceramic filter plate can effectively remove all kinds of inclusions with fineness up to micron level in aluminum liquid, make aluminum liquid into a steady laminar flow, which is conducive to filling.

● It has a unique mullite-corundum structure, good mechanical strength and chemical stability, excellent resistance to aluminum liquid erosion performance.

● It can obtain stable filtration effect by strict control of hole size and through hole rate.

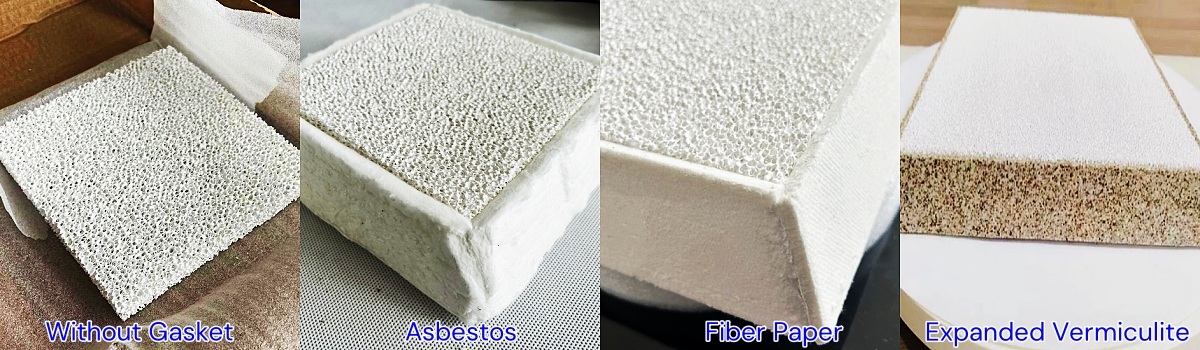

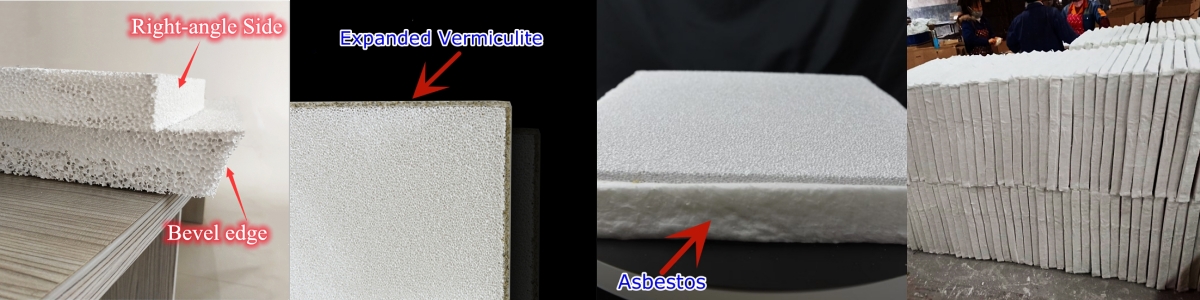

● The ceramic foam filter plate is surrounded by a sealing ceramic fiber liner, which facilitates the seal of the filter plate in the filter box to ensure that there is no metal liquid sideflow.

| Color | White |

| Edge Covering | Asbestos---Normal |

| Expanded Vermiculite---Superior | |

| PPI | 10/20/30/40/50/60(Customized) |

| AL2O3 Content | ≥83% |

| Porosity | ≥85% |

| Proportion | 0.3g/cm³-0.45g/cm³ |

| Refractory temperature | ≥1500℃ |

| Bending strength | >0.5Mpa |

| Thermal shock resistance | 750℃/5times |

| Solubility | Under the temperature of metal aluminum and aluminum alloy solution, the filter equipment will not chemically react with the solution and dissolve. |

| Certificate | ISO9001:2015 |

| REACH & RoHS |

| Dimension(mm) | Tolerance(mm) | Thickness(mm) | Rake Angle | Tortuosity(mm) | Diagonal Line | Effective Filtration Area(%) | Filtration Flow Range(Kg/min.) |

| 12"/(305*305*50) | ±3 | 50±1 | 17.5°+1° | Max.4 | <1% of side length | 82 | 52-158 |

| 15"/(381*381*50) | ±3 | 50±1 | 17.5°+1° | Max.4 | <1% of side length | 86 | 86-255 |

| 17"/(432*432*50) | ±3 | 50±1 | 17.5°+1° | Max.4 | <1% of side length | 87 | 112-345 |

| 20"/(508*508*50) | ±4 | 50±1 | 17.5°+1° | Max.4 | <1% of side length | 89 | 158-480 |

| 23"/(584*584*50) | ±4 | 50±1 | 17.5°+1° | Max.4 | <1% of side length | 91 | 212-645 |

| Item | Allowable variation | |||

| ≤381mm | 381mm~430mm | ≥430mm | ||

| Side length allowable variation(mm) | ±3 | ±4 | ±5 | |

| Diagonal line allowable variation(mm) | ±5 | ±7 | ±9 | |

| Plane clearance allowable variation(mm) | ≤3 | ≤6 | ||

| Thickness allowable variation(mm) | ±2 | |||

| Side rake allowable variation(°) | ±1° | |||

Remarks: 1. Diagonal deviation refers to the difference between the lengths of two diagonals on large surface of filter plate. 2. The plane gap is to place the large surface of filter plate on platform, and measure the gap between filter plate & platform. 3. Side bevel refers to the angle between side bevel and large surface. 4. The filter plates involved in the table are all products with a theoretical thickness of 50mm & a side inclination angle 17.5°. | ||||

● Superior dimensional tolerances.

● Stable chemical property.

● Excellent filtration efficiency.

● Excellent mechanical strength.

● Resistant to corrosion and thermal shock resistance.

● Beveled edges and compressible gasket.

Aluminum Ceramic Foam Filter is mainly applied to the aluminum and aluminum alloys fusion filter equipment of continuous casting, half continuous casting, gravity casting, and low-pressure casting. It is also applied to other non-ferrous metal precision casting, gas-solid and liquid-solid separation medium, high-temperature gas filter, chemical filling, sound absorbing material and catalysis carrier, etc. Get a quote.

This high-tech ceramic product has three-dimensional connected pores, and its shape, pore size, permeability, surface area, and chemical properties can be adjusted appropriately.

The whole body is composed of many uniform and countless micropores. When the fluid passes through these tiny pores, suspended substances, colloidal particles, and macromolecules are trapped on the surface of the alumina ceramic foam medium, and the fluid passes through the microporous channel to produce various physical effects, achieving mechanical filtration purification or diffusion, fluidization, and other effects.

Application:

Filtration Of Molten Aluminium

Molten Aluminium Alloy

Ductile and steel alloy

Ferrous metals including grey

Copper-based alloys

Look forward to hearing from you:

Contact Us

+86 158 3011 4065

Guoruiyuan Building, ShengLi North Street, Chang'An District, Shijiazhuang City, Hebei Province, China.

Navigation

Navigation