Jan. 08, 2024

As a filter equipment often used in industrial production, cap filter plays an important role in metal smelting industry. In recent years, with the development of industry, its application is more and more wide.

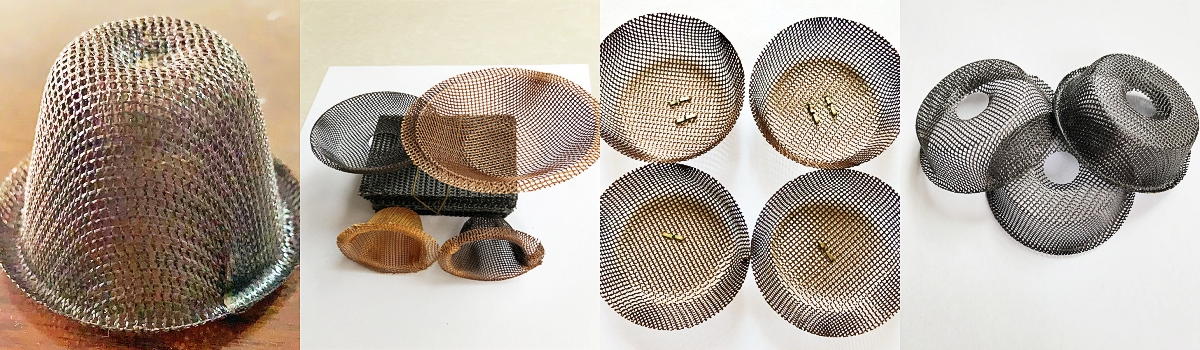

The Fiberglass cap-style is woven with special high-twist & high-strength alkali-free fiberglass yarn (E-fiberglass), special post-treatment, coated with resin and carbonized by high temperature(Very important point). The maximum temperature resistance can reach 900 ℃.

There are two models:

● Normal yellow(brown) color type (without high temperature carbonization)

● Black color type (with high temperature carbonization)

Application:

It is widely used in automobile and motorcycle wheels, cylinder pistons, aluminum rods, aluminum materials, aluminum ingots, aluminum plates and precision casting of all types of aluminum alloy casting.

Functions:

● Effectively remove impurities,

● Reduce turbulence and eliminate air bubbles,

● Improving the quality of castings and reducing costs,

● Does not pollute the aluminum liquid, Does not affect the chemical properties of the metal,

● Aluminum waste containing the filter mesh, aluminum liquid from sprue and the riser can be directly returned to the furnace for remelting, greatly reducing costs.

The KEY points of fiberglass cap filter working temperature:

● It is divided into working temperature and softening temperature:

1. The working temperature of aluminum water filter is 700~800 ° C.

2. The softening temperature is 900 ° C.

We need to choose the suitable filter according to the different pouring temperatures of liquid aluminum, rather than let the filter working temperature affect the pouring temperature of the liquid metal in turn, which will cause more casting defects and lose the meaning of filtration.

● The reasons for the change of fiberglass cap filter temperature:

1. The initial temperature of liquid aluminum is too low. This is a more common reason.

2. The design of pouring system is unreasonable. The heat dissipation is too fast, or the metal is not preheated, so that the metal liquid is sharply cooled in the process of entering the cavity.

3. Operation error. The initial overheating temperature reservation is too high. As far as possible to ensure that the casting process meticulous specification is the main way to solve the problem.

● The control measures of use temperature of fiberglass cap filter:

1. Do not exceed the filter operating temperature

From the perspective of filtration, exceeds the working temperature limit, the filter will lose its original performance because of overheating softening, and it will not play the role of filtration. Therefore, the working temperature of the filter must not be exceeded.

2. Use induction furnace for smelting

In production, using induction furnace melting can better control the liquid metal temperature. Reasonable control of the pouring process, to consider the time required for each step, to avoid some step that waited for a long time to make liquid cool. This requires that the liquid metal initially have a certain overheating temperature, and pay attention to heat preservation at any time during the pouring process.

3. Increase the temperature of liquid aluminum when coming out from smelting furnace.

It is necessary to increase the temperature of the aluminum liquid and appropriate sedation to facilitate the floating and aggregation of non-metallic inclusions. Remove the residue on the surface of the liquid aluminum, and put the covering agent (perlite, plant ash, etc.) on the surface of the liquid aluminum to prevent the oxygenation of the liquid aluminum. Choose the appropriate pouring temperature, try not to lower than 1350℃.

4. Shorten the solidification time

Under normal circumstances, the higher the pouring temperature, the greater the tendency of graphite to float, because the casting in liquid state for a long time is conducive to the precipitation of graphite. It is found that if the solidification time is shortened, the floating tendency of graphite decreases with the increase of pouring temperature.

In summary, in the case of grasping a reasonable pouring time, the appropriate working temperature of the filter is very reasonable for the casting, after all, the design of fiberglass cap filter is to reduce the scrap rate of the casting.

why are Cap Filters so widely used?

First of all, it is imperative to reduce the waste of resources in the metal industry. It can effectively reduce more than half of the slag, impurities caused by the waste phenomenon. This is also the main reason for the wide use of filters, also the main trend.

Secondly, it can effectively remove non-metallic inclusions in liquid metal, which is also a big use of cap filter. It can significantly improve the casting structure and mechanical properties, so that the casting quality is higher, better quality, reduce the rejection rate, reduce tool wear.

Thirdly, Cap Casting filter is not only used to reduce casting porosity, but also can effectively reduce casting surface defects and increase process yield. It can effectively screen and adsorb small pre-slag, so that the quality of metal castings is better, the performance is better, to create high-quality castings.

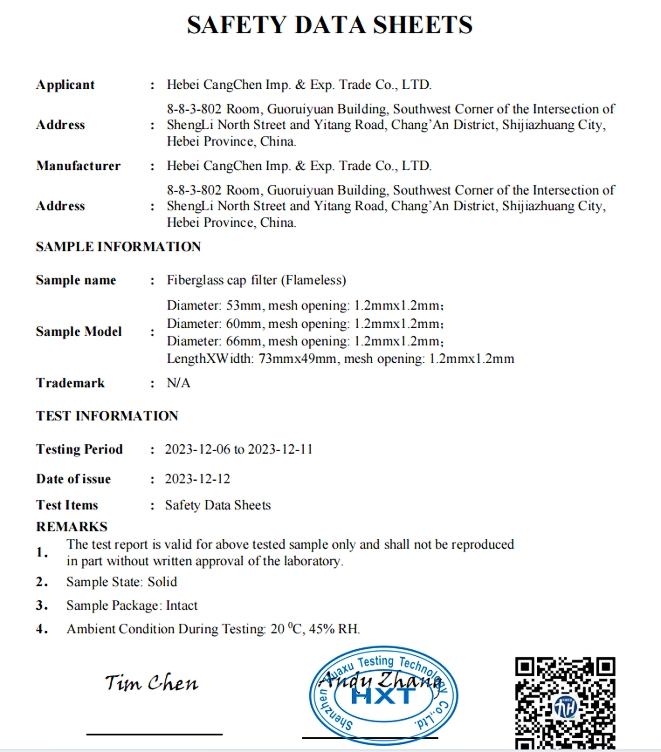

Hebei Cangchen fiberglass cap filters has been passed the SDS test, all shapes and mesh opening can be customized according to your samples and drawings.

Contact Us

+86 158 3011 4065

Guoruiyuan Building, ShengLi North Street, Chang'An District, Shijiazhuang City, Hebei Province, China.

Navigation

Navigation